Process for sifting a mixture of a milled material and a fluid, and mill sifter

A classifier and grinding machine technology, applied in the direction of classification, chemical instruments and methods, and devices whose axial direction of the swirling flow can be reversed, etc., can solve problems such as pressure loss in the production system of finished materials that affect the smooth operation of the mill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

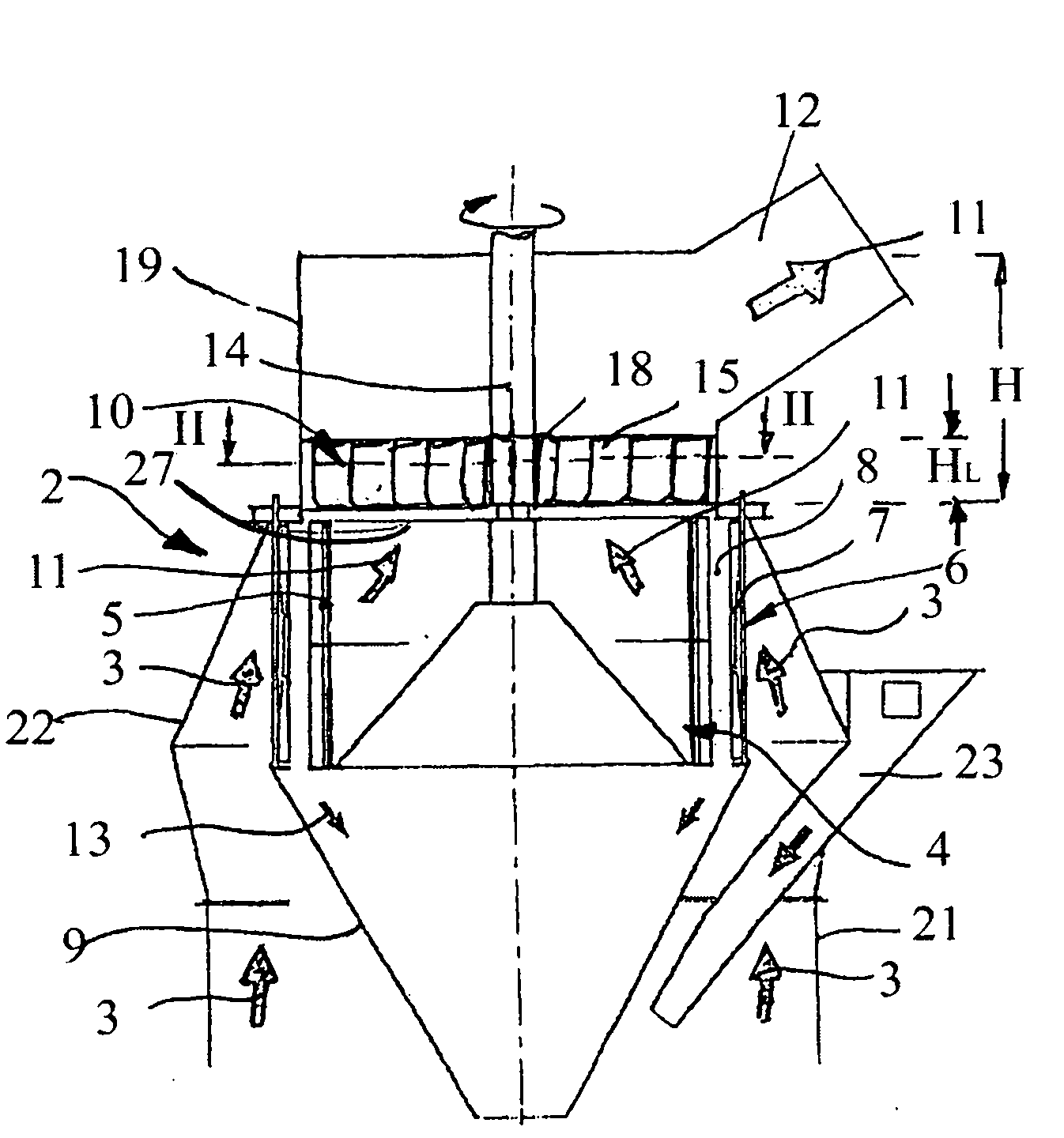

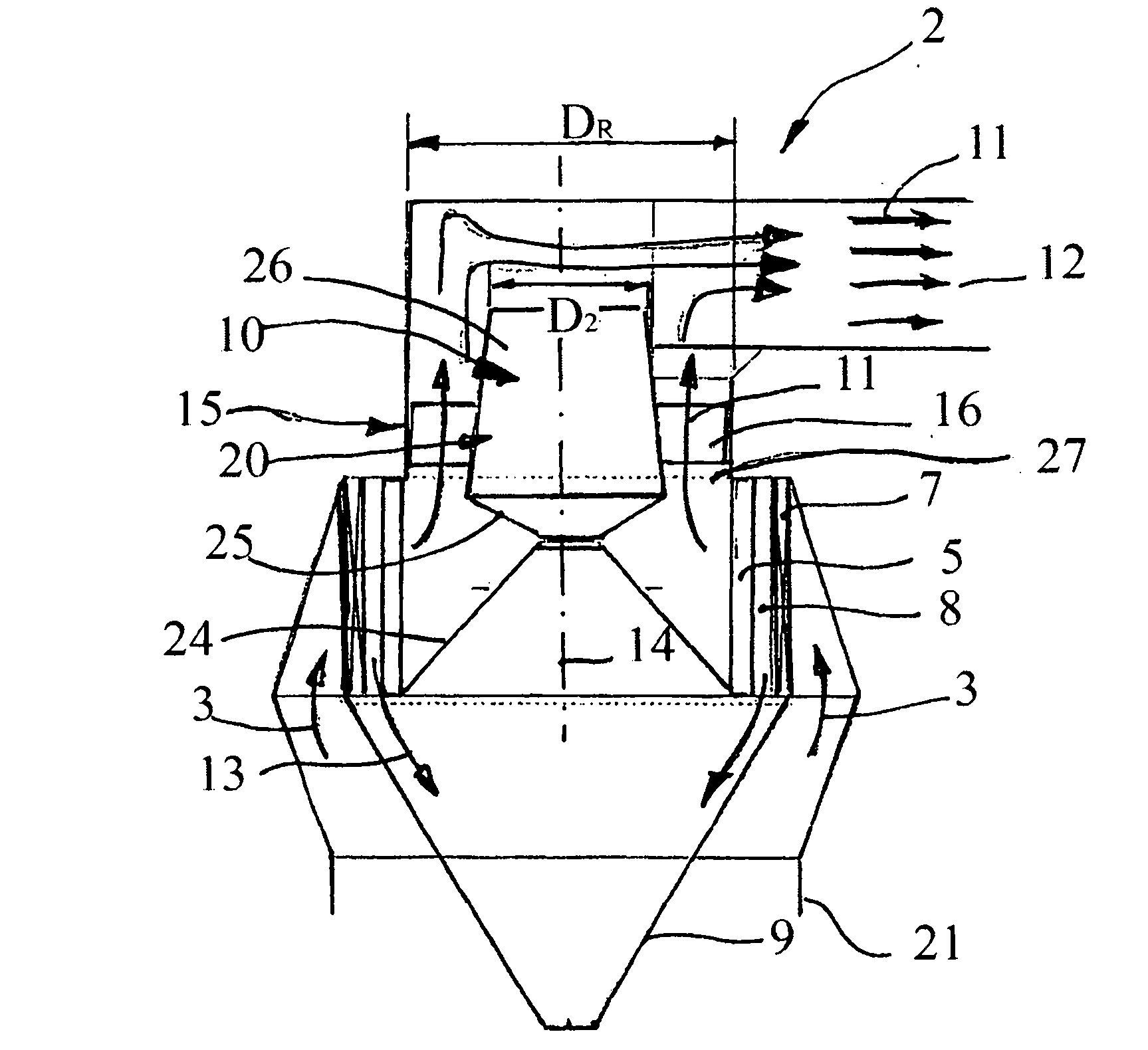

[0045] figure 1 The mill classifier 2 integrated with the roller mill is shown. Only the upper region of the mill housing 21 of the roller mill is shown, with the side grinding stock supply 23 . The classifier housing 22 is connected to the grinding material housing 21 .

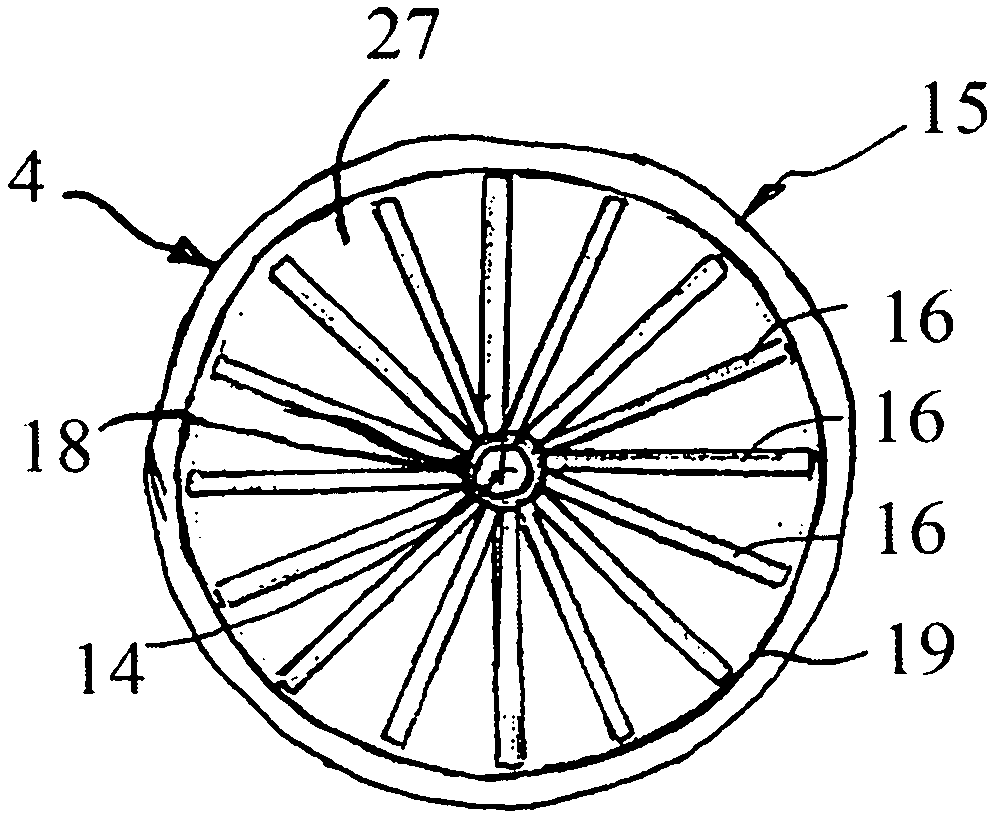

[0046] The mill classifier 2 comprises a dynamic classifier part 4 which in this embodiment is a bar rotor or a rotor with rotor blades 5 arranged coaxially around a rotor axis 14 . A guide vane ring 6 with guide vanes 7 is arranged coaxially to the dynamic classifier part 4 , the guide vanes 7 being stationary and adjustable. The ground material fluid mixture 3 from the grinding chamber enters the classifying chamber 8 in swirling flow from the grinding chamber, where the coarse material particles 13 are separated and supplied via the sand cone 9 as coarse material discharge for regrinding.

[0047] The fine material fluid flow 11 (also called dust gas mixture) enters the classifier outlet housing 19 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com