Extension-type spark plug

一种火花塞、细长的技术,应用在火花塞领域,能够解决增加制造过程成本、制造和维修后勤问题、复杂设计要求改造指示等问题,达到增加公差极限、使用寿命增加的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

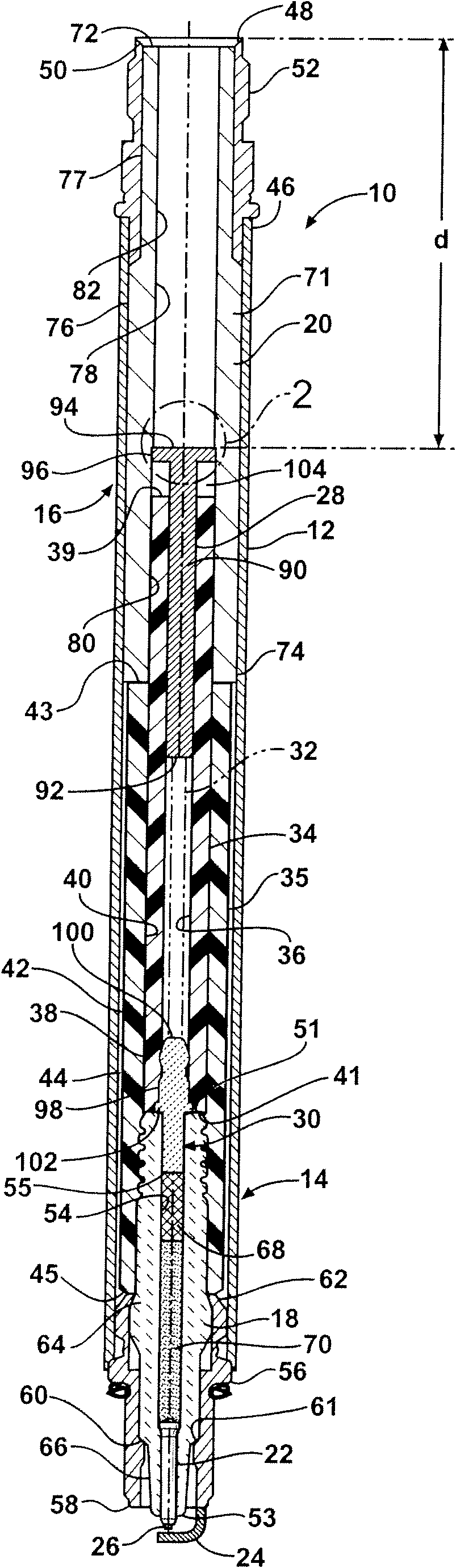

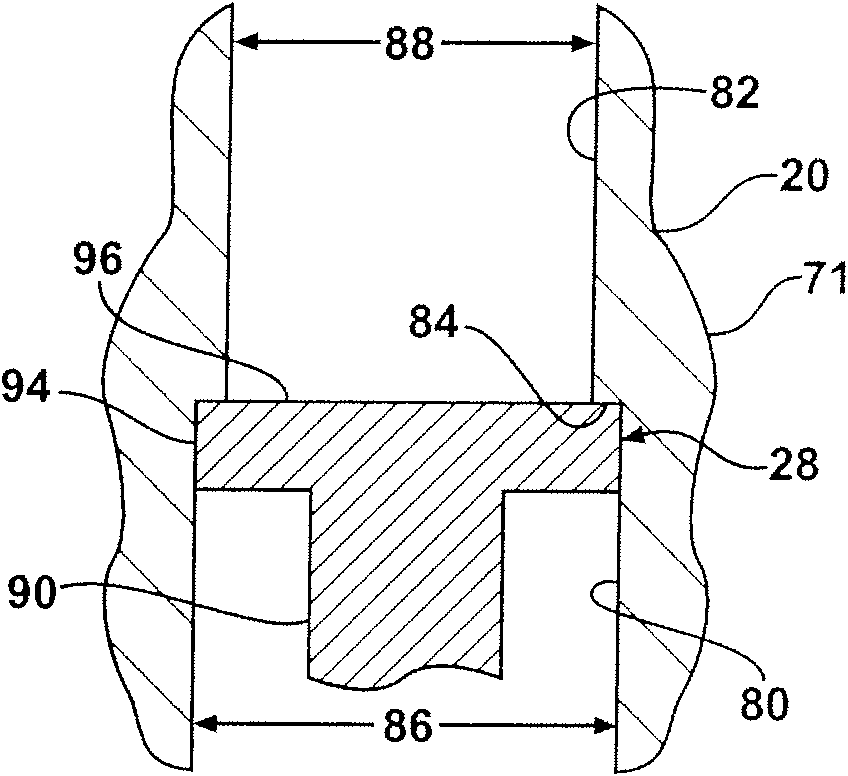

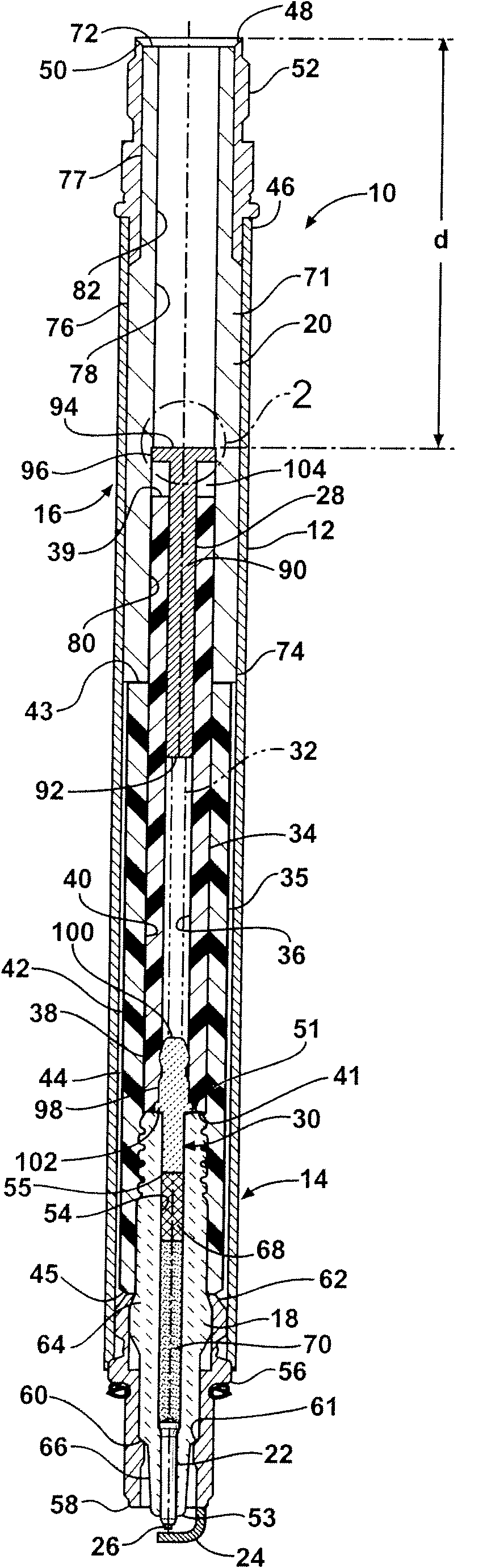

[0012] Referring to the drawings in more detail, FIG. 1 shows a cross-sectional view of an elongated spark plug 10 constructed in accordance with a presently preferred embodiment of the present invention. The spark plug 10 is of the type used in industrial engines and other specific applications where access to the spark plug 10 for repair and replacement purposes is extremely limited. The spark plug 10 includes a mounting housing or tube 12 made of a metallic material, such as stainless steel or some alloy steel. Mounting duct 12 houses a lower assembly, generally indicated at 14 , and an upper assembly, generally indicated at 16 . Both lower assembly 14 and upper assembly 16 are at least partially made of a dielectric material, such as ceramic, and include a lower dielectric insulator 18 and an upper dielectric insulator 20, respectively. The lower insulator 18 houses an ignition electrode 22 adjacent a ground electrode 24 with a spark gap 26 therebetween. The upper assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com