Concrete mixer helical blade design method based on equal changeable angle helical curve

A technology of concrete mixer truck and variable angle screw, applied in the field of machinery, can solve problems such as single

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A method for designing the helical blade of a concrete mixer truck based on an equal-angle helix, comprising the following steps:

[0024] (1) Establish the correct helical curve of the blade root and the blade top, and the blade root shape line equation is:

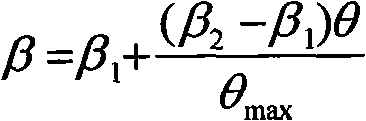

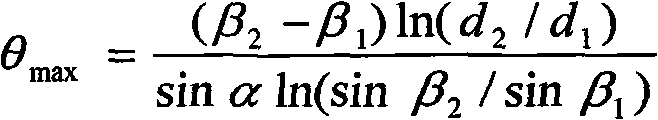

[0025] When β is a variable and changes linearly with θ, β can be expressed as:

[0026] β = β 1 + ( β 2 - β 1 ) θ θ max

[0027] In the formula, r is the radius of the cylinder, β is the helix angle, θ is the helix rotation angle, θ max Maximum Helix Angle

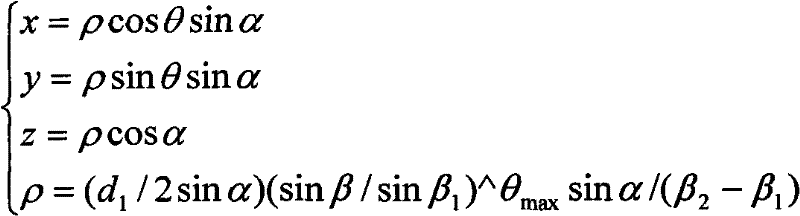

[0028] Then the equation of the constant-angle helix of the conical segment is:

[0029] x = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com