Hydraulic aggregate for underground transportation vehicle

A technology for hydraulic units and transportation tools, which can be used in fluid pressure actuation system components, mechanical equipment, fluid pressure actuation devices, etc., and can solve problems such as limitations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

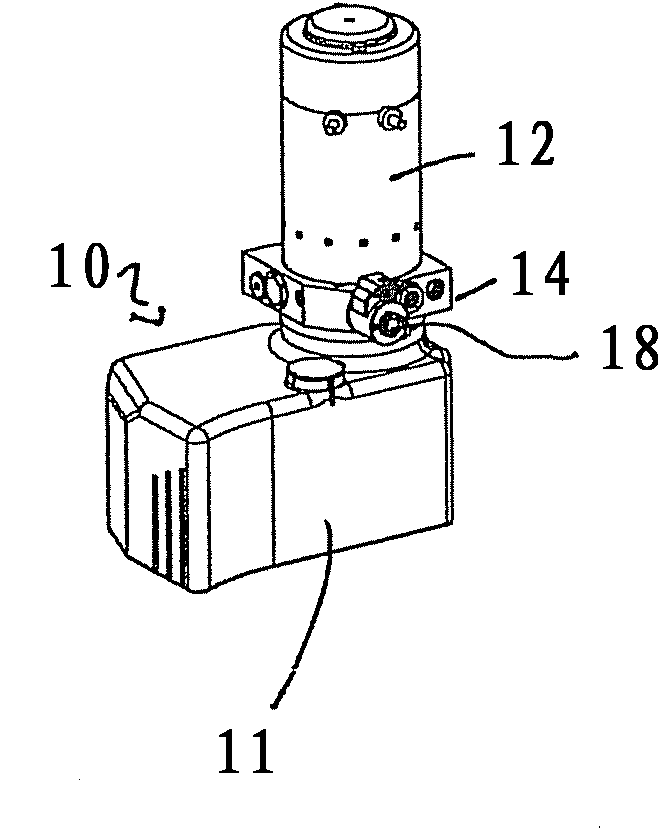

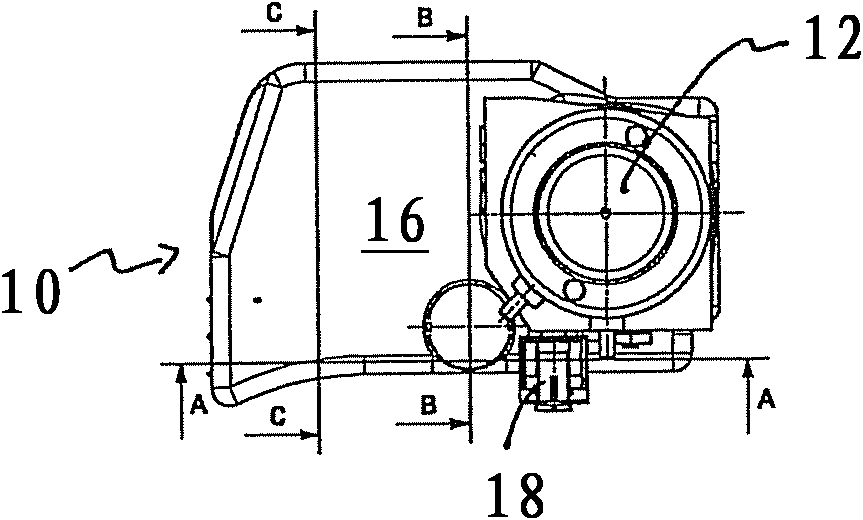

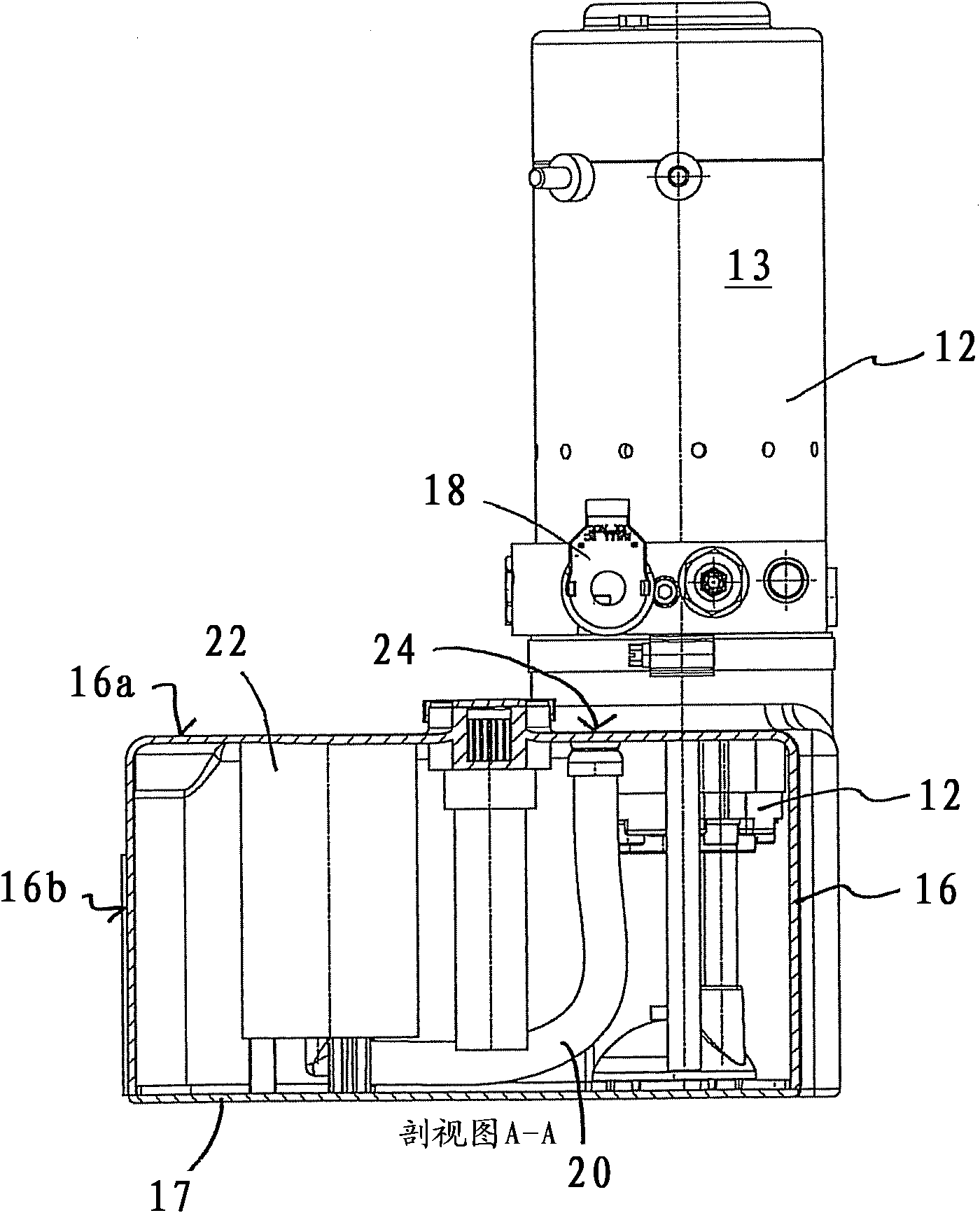

[0029] figure 1 and 2 A compact hydraulic unit 10 is shown with an installed motor-pump unit 12 and a tank 11 . The tank 11 is composed of a tank body 16 and a tank cover 17 . The tank shell 16 has an upper side 16 a and a surrounding side wall 16 b which is laser welded to the substantially planar tank cover 17 . This weld is welded on the end face of the side wall 16b facing away from the upper side 16a to the surface of the tank top plate 17 pointing inwards towards the tank interior. If the welding is done at the contact surface between the tank cover and the tank shell, the laser thus only follows the two-dimensional contour of the tank circumference and no height adjustment is necessary.

[0030] Mounted on the motor-pump unit 12 is a valve housing 14 which has a solenoid valve 18 . With the hydraulic unit 10 shown, for example, lift cylinders (not shown) in a ground vehicle can be actuated. When the motor 13 in the motor-pump unit 12 is switched on, hydraulic mediu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com