Contact element module and connector using same

A contact and connector technology, applied in the coupling of optical waveguides, etc., can solve the problem that the ceramic sleeve cannot be replaced, and achieve the effect of convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

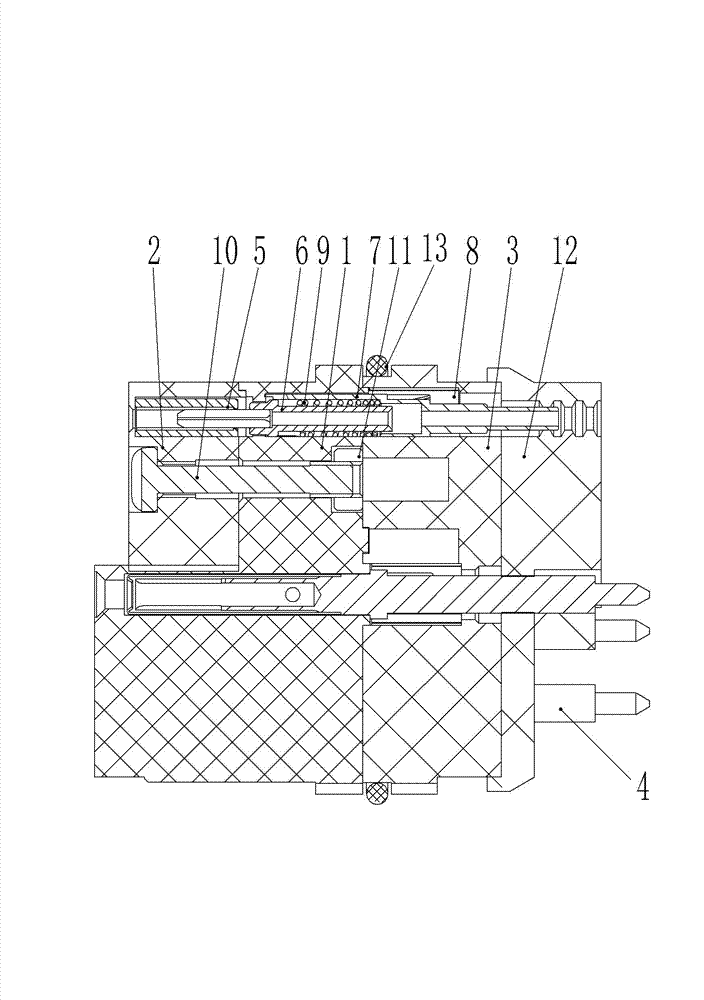

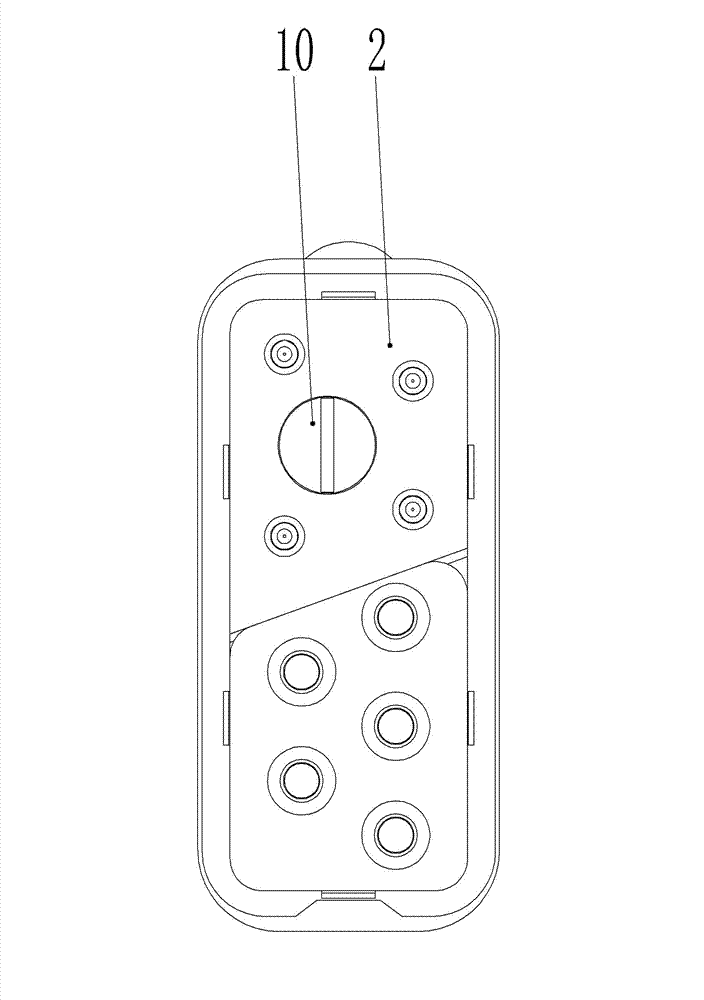

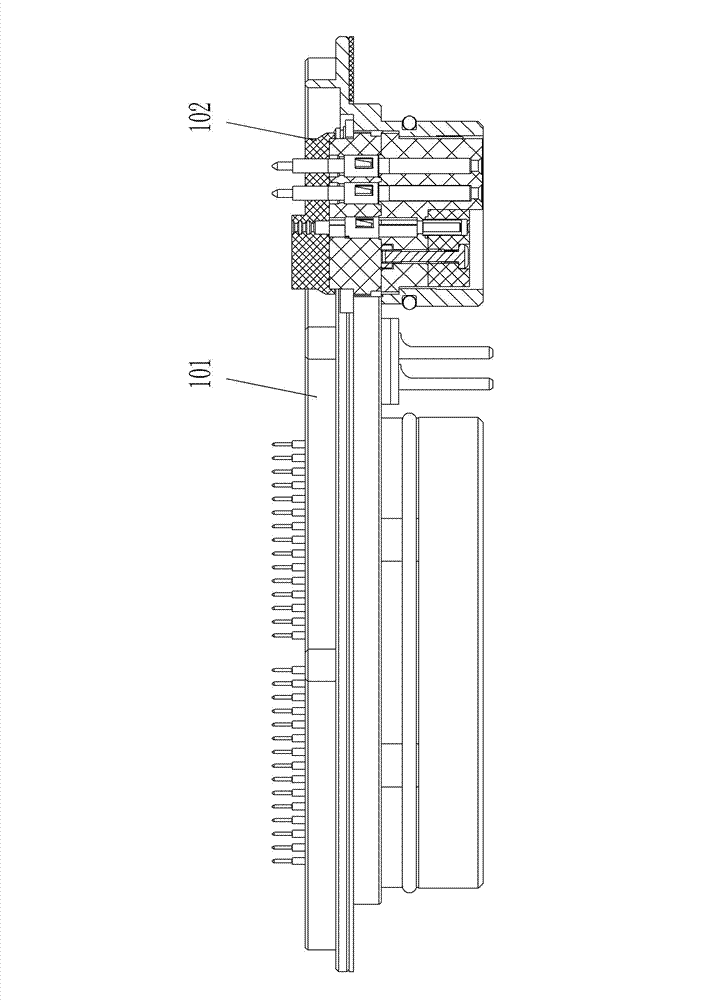

[0021] Embodiment 1 of the contact module of the present invention, such as Figure 1-2 As shown, the contact module is a photoelectric hybrid contact module, which has an insulator 1 and a front insulating pressure plate 2 and a rear insulating pressure plate 3 respectively arranged at the front and rear ends of the insulator 1. The insulator 1 is equipped with an optical contact and an electrical contact 4. , the optical contact includes a ceramic pin 5 and a tail tube 6 that are assembled together one after the other. The outer part of the ceramic pin is provided with a ceramic bushing, and the tail tube 6 is provided with a contact shell movable along the axial direction. The body 7 and the contact housing 7 are located in the assembly hole on the insulator 1 and cooperate with the inversion edge stopper provided at the front end of the corresponding assembly hole through its front end, and the rear insulating pressure plate 3 is bonded to the rear end of the insulator 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com