Transmission device

A kind of transmission device and active technology, which is applied in the direction of transmission device, transmission device parts, friction transmission device, etc., can solve the problems of increasing energy consumption and complex structure, and achieve the effect of reducing energy consumption and simplifying power configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

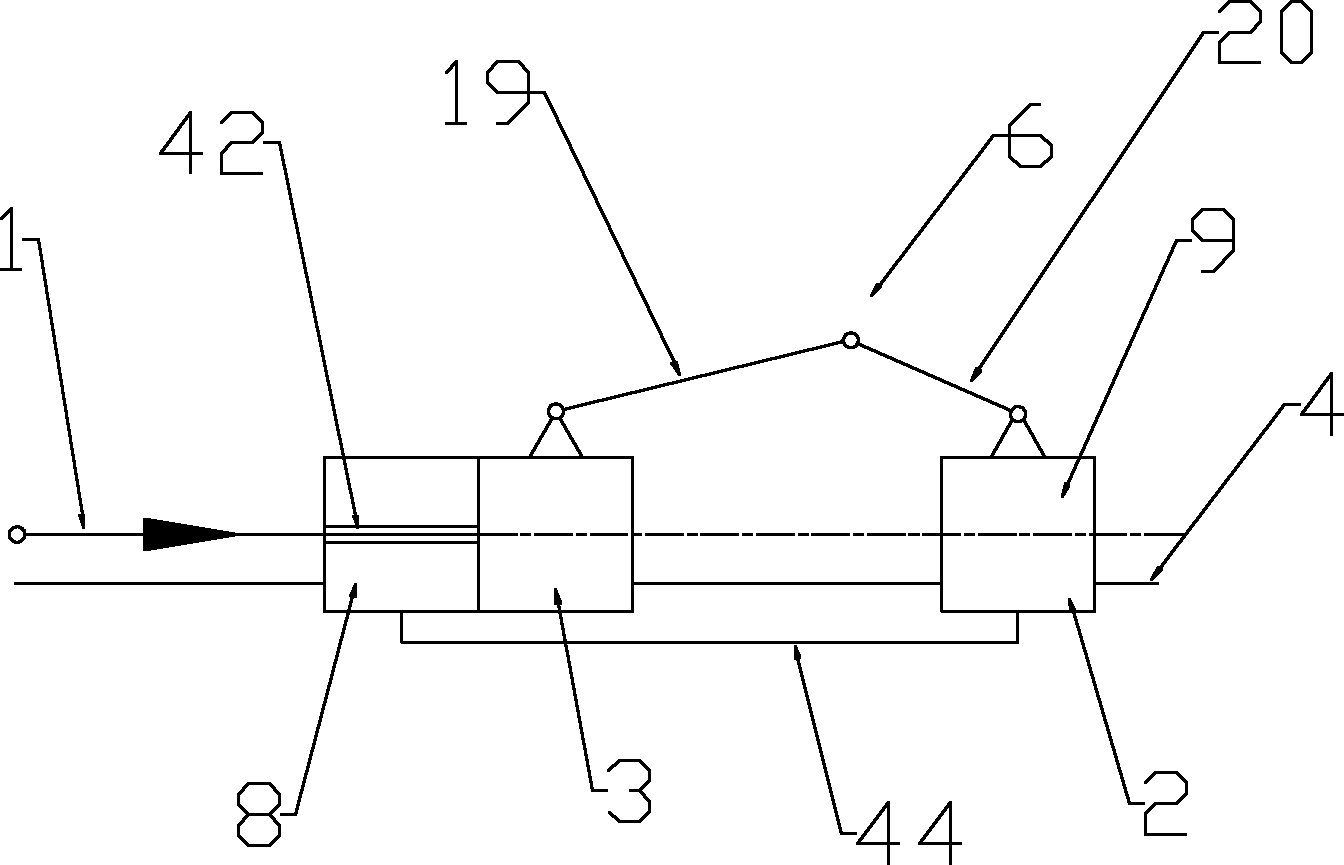

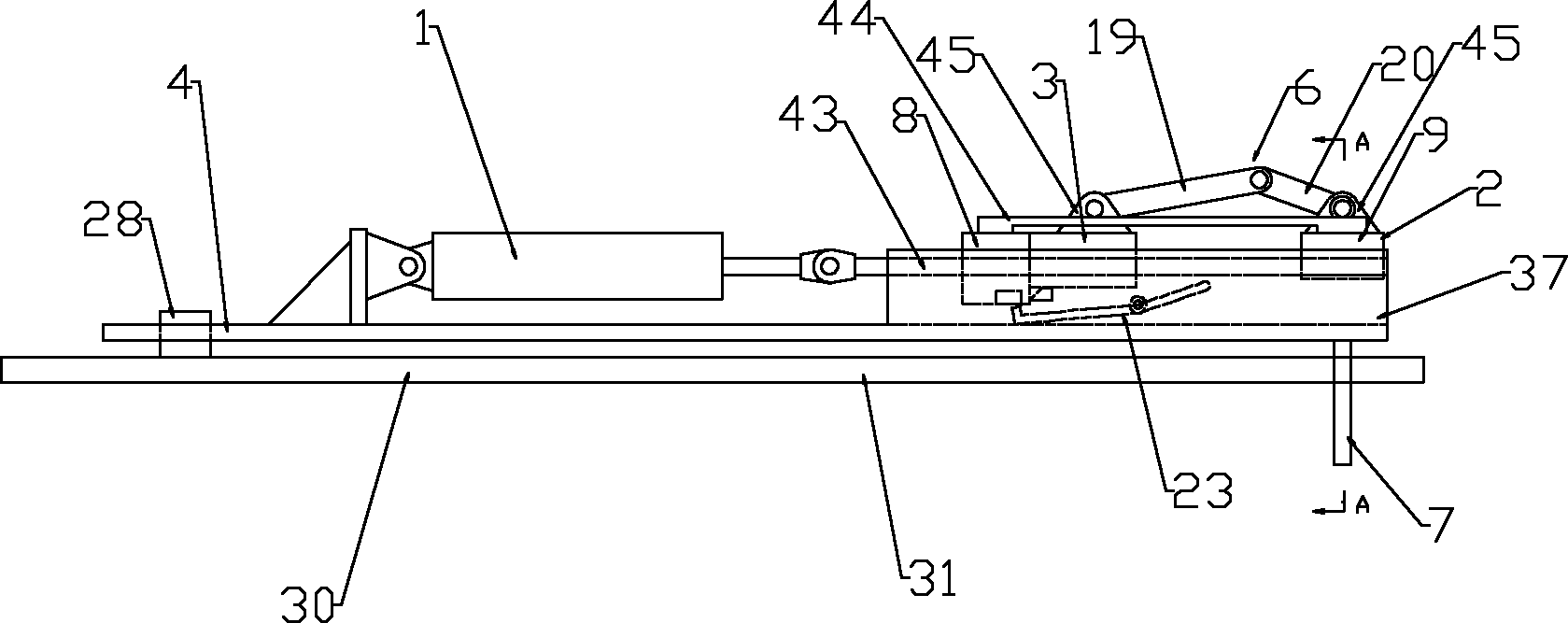

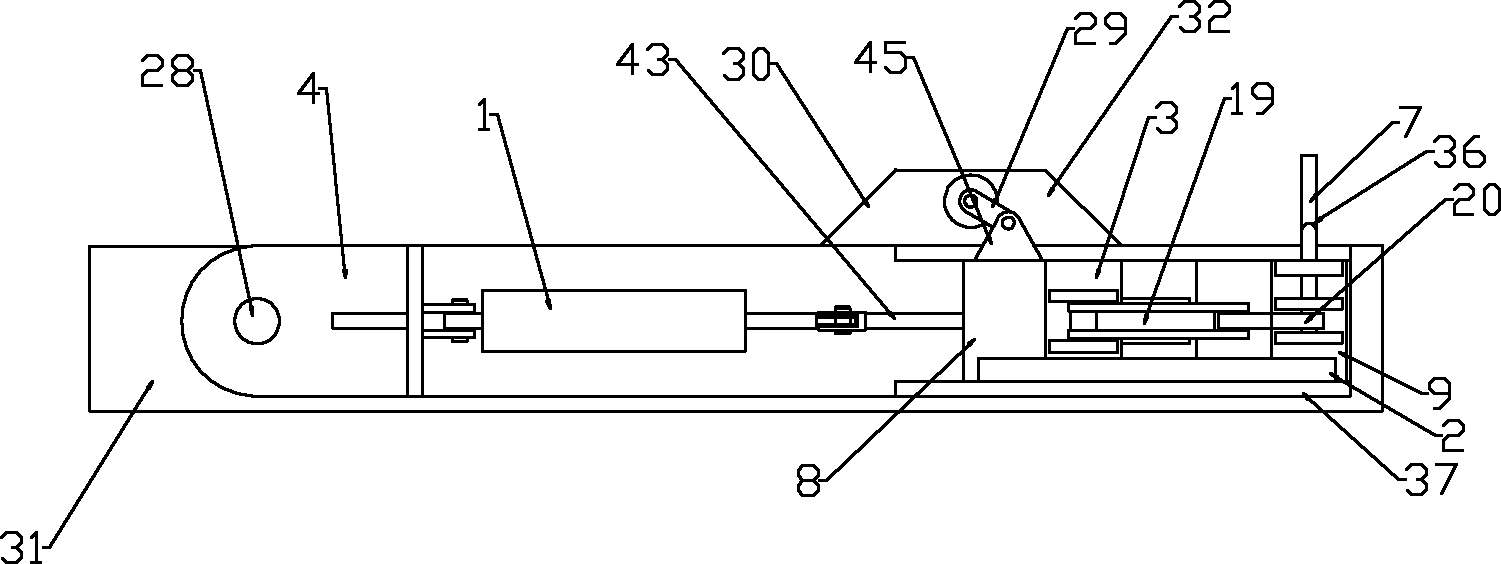

[0067] The passive slider 2 may have only one slider or two or more sliders. In order to facilitate the connection and release between the passive slider 2 and the active slider 3, according to a preferred implementation of the present invention In this way, the passive slider 2 includes a first slider 8 and a second slider 9. The first slider 8 and the second slider 9 are fixedly connected and spaced apart, and the active slider 3 is located in the first slider. Between the sliding block 8 and the second sliding block 9, the first sliding block 8 is pivotally connected to the side portion 32 through the first connecting rod 29. The first sliding block 8 and the second sliding block 9 may be fixedly connected by various suitable methods, for example, fixedly connected by a connecting rod 44. Specifically, one end of the connecting rod 44 is fixedly connected to the first sliding block 8 (for example, by welding or fastening connection), and the other end of the connecting rod 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com