Impedance composite type sound absorbing plate

A sound-absorbing panel and composite technology, applied in the direction of sound-producing equipment, instruments, etc., can solve the problems of unsightly appearance, inconvenient installation and fixing of marine sound-absorbing panels, and uneven installation holes, so as to achieve overall beauty and neatness and better sound absorption effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

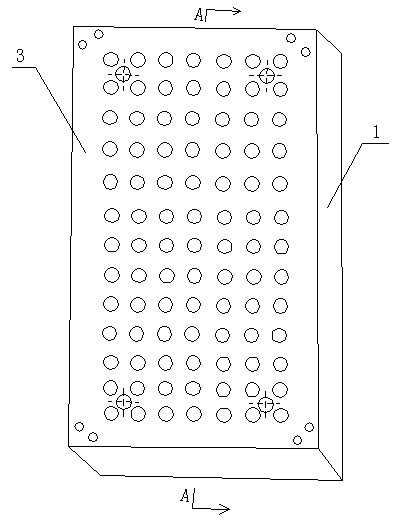

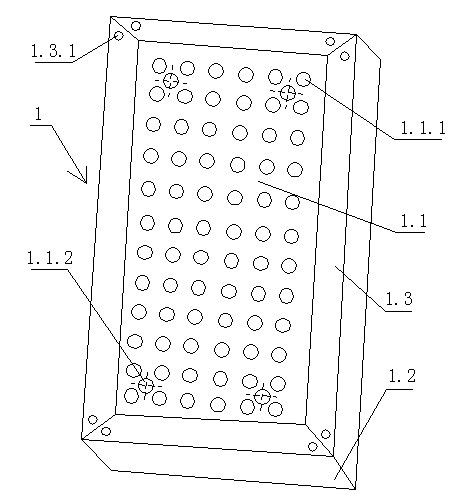

[0023] see Figure 1 to Figure 7 , The present invention relates to an impedance composite sound-absorbing panel, comprising a panel 1 , a sound-absorbing material 2 and a back panel 3 .

[0024] The panel 1 includes a panel main body 1.1, the four sides of the panel main body 1.1 are bent vertically upward to form a vertical side 1.1.1, and the upper parts of the four vertical sides 1.1.1 are bent horizontally inward to form a flange 1.3, the panel main body 1.1 is provided with several panel small holes 1.1.1 and four panel installation holes 1.1.2, and each of the left and right sides of the surface of the four flanges 1.3 is provided with a panel positioning hole 1.3.1.

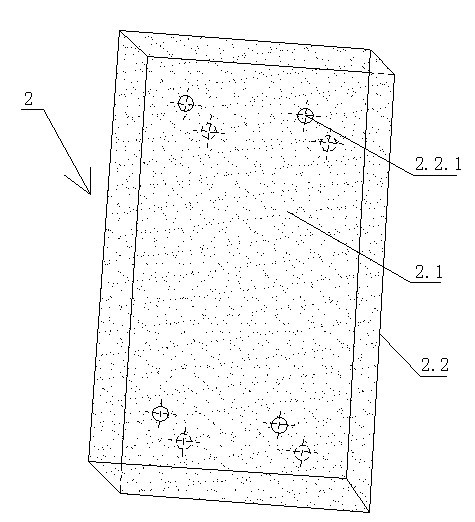

[0025] The sound-absorbing material 2 includes glass wool 2.1 and glass mat 2.2. The glass wool 2.2 is wrapped outside the glass wool 2.1. The shape of the glass wool 2.2 is consistent with the shape of the panel main body 1.1. There are four glass mat installation holes 2.2.1 on the surface.

[0026] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com