Through Hole Processing Method

A processing method and high aspect ratio process technology, applied in the field of semiconductor manufacturing and packaging, can solve the problems of difficulty in conformal coverage of copper barrier layer and copper seed layer, affecting TSV interconnection characteristics, and difficulty in insulating layer technology, so as to achieve reduction The possibility of failure of small TSV devices, the effect of improving coverage and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

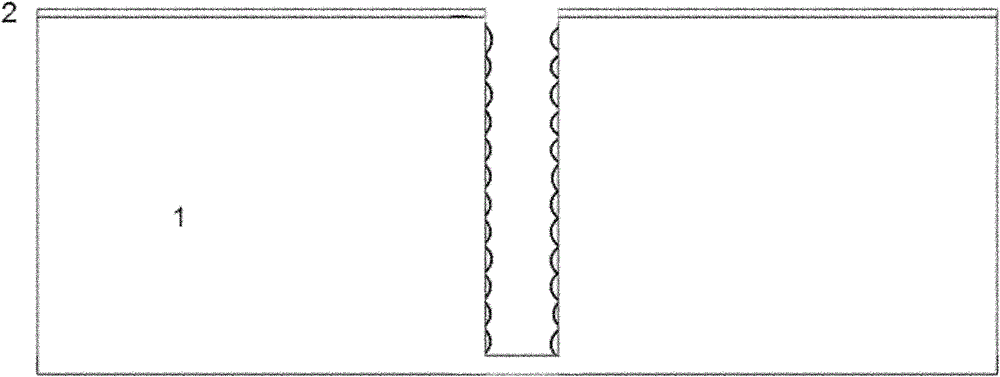

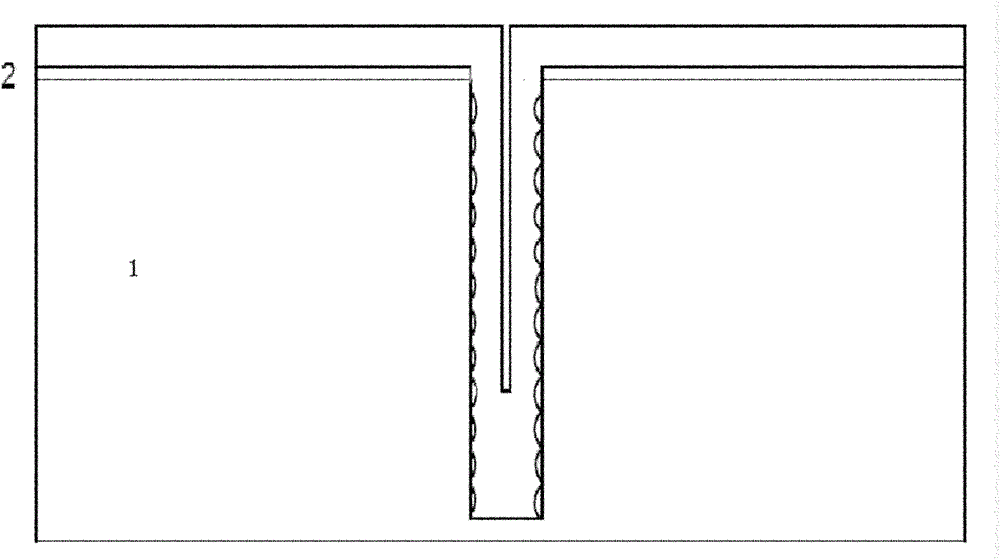

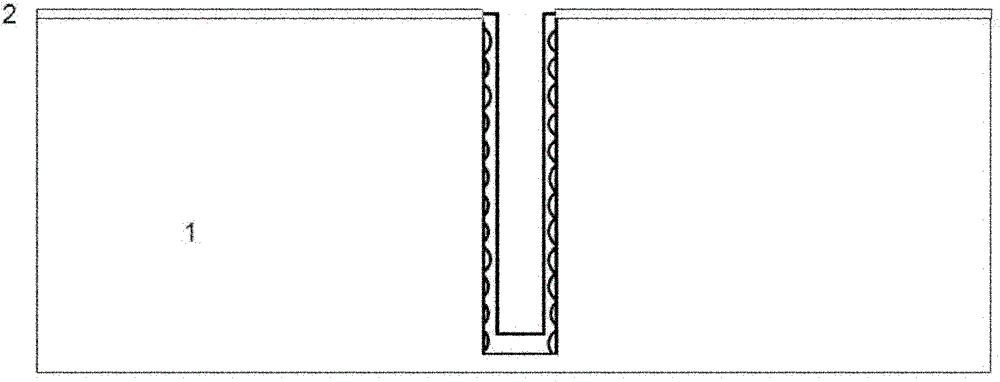

[0030] In a preferred embodiment of the present invention, a method for eliminating the influence of the scallop shape of the side wall of the TSV via hole on the subsequent process and forming an insulating oxide film with good conformal coverage is provided, including: providing a hard A semiconductor substrate with a mask pattern, the hard mask pattern corresponds to a through hole; using the hard mask pattern as a mask, Boschetch is used to etch the semiconductor substrate to form a through hole; Use high aspect ratio process (High AspectRatioProcess, HARP) to partially fill the through-silicon hole; use a one-step high-temperature annealing process to heat-treat the silicon wafer; use SiCoNi to modify the morphology of the partially filled t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com