Weight adjusting device with screwing type guiding sleeve

A technology for adjusting devices and guide sleeves, applied to heavy objects, dumbbells, etc., can solve problems such as complex structures, imperfections, and time-consuming, and achieve the effect of simplifying the weight adjustment structure and coordinating the pick-and-place process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

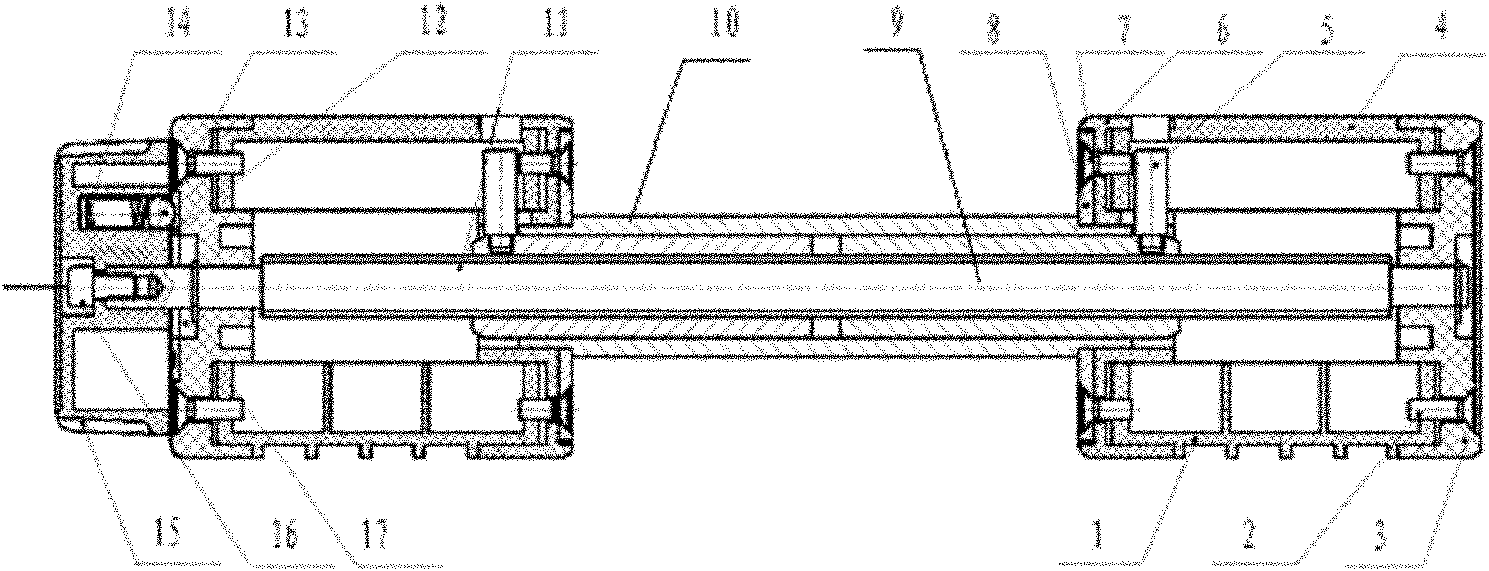

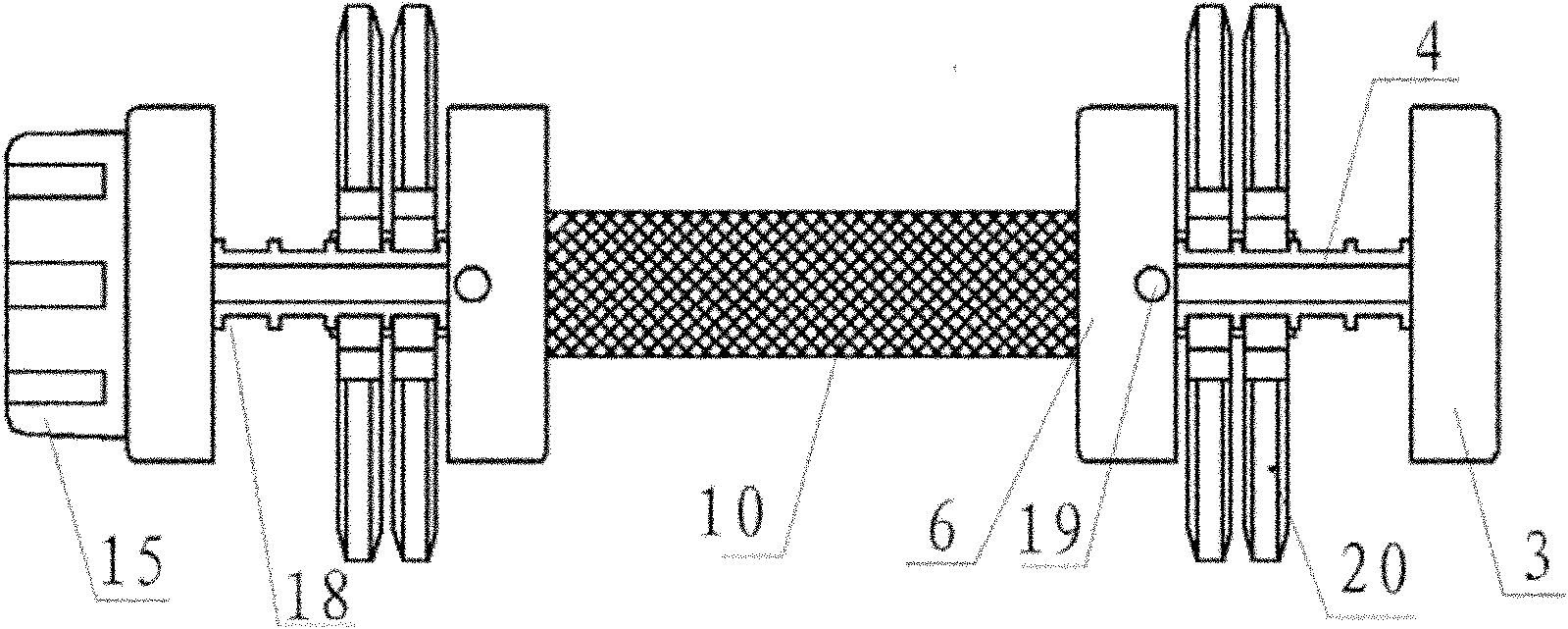

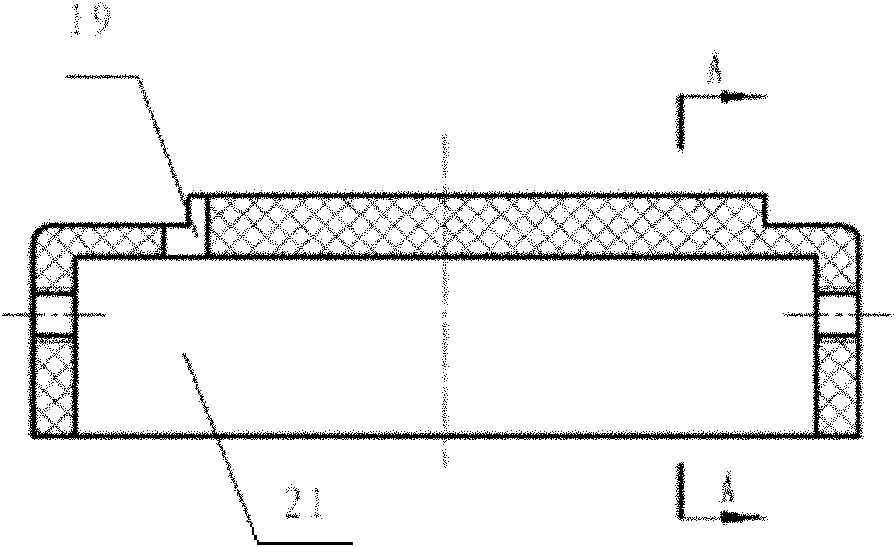

[0021] The schematic diagram of the guide sleeve screw-in weight adjustment device of the present invention is as follows: Figure 1-Figure 6 As shown, it includes a handle cover 10, two supporting units, a counterweight adjustment mechanism and a counterweight 20, and the schematic diagram of the counterweight 20 is as follows Figure 6 As shown, it includes a disc-shaped body 25, a central hole 24 is arranged in the center of the body 25, and an opening groove 23 is arranged on the body, and the opening groove 23 passes through the central hole 24 in a radial direction and opens to one side. The counterweight adjustment mechanism includes a screw cap 15 , an adjustment spring 14 , a steel ball 13 , a positioning plate 12 , an adjustment screw 11 , two guide sleeves 9 and two guide posts 3 . The support unit includes an outer end cover 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com