Protective sheet and the applications thereof

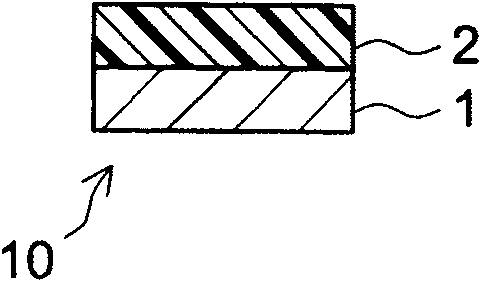

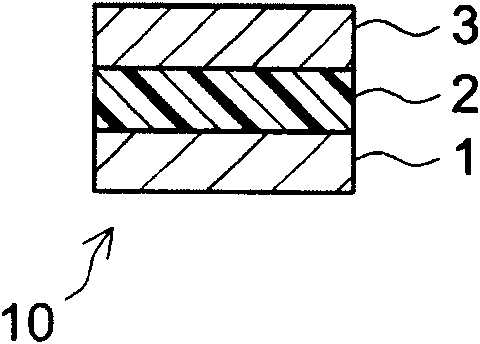

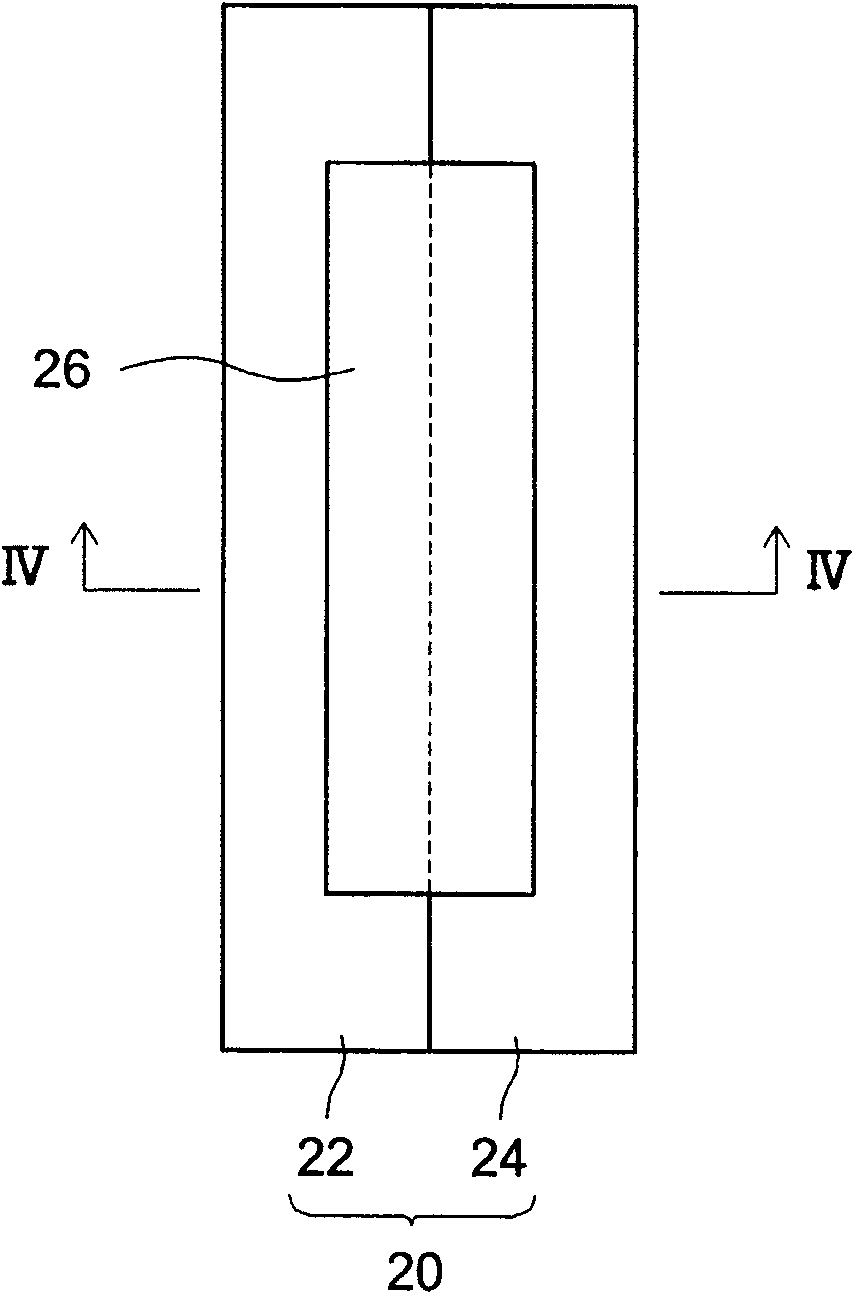

A protective sheet, single-sided technology, applied to film/sheet adhesives, transportation and packaging, thin material handling, etc., can solve the problem of productivity decline, protective sheet handling (easily reduced operability, reduced workability, etc.) question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0065] Hereinafter, some examples related to the present invention will be described, but the present invention is not intended to be limited to the contents shown in the examples. In addition, in the following description, "part" and "%" are a mass basis unless otherwise indicated.

[0066] In addition, each characteristic in the following description was measured or evaluated as follows, respectively.

[0067] [tensile modulus of elasticity]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com