Heat sink material

A heat dissipation and base material technology, applied in the direction of electrolytic coating, thin material processing, coating, etc., can solve problems such as difficulty in correspondence, shape limitation of heat dissipation materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

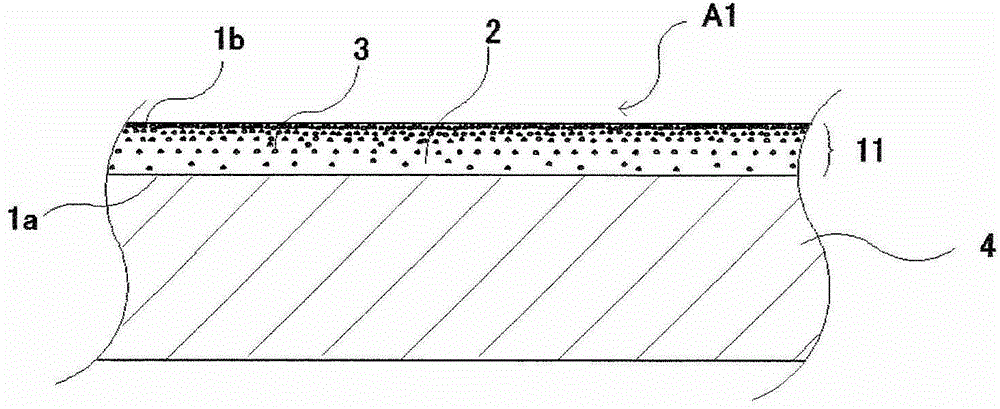

[0067] use Figure 7 The indicated electroplating device (the anode material is an electrolytic nickel plate) uses a stainless steel plate (20mm×20mm×0.5mm) as a base material, and the heat dissipation material of Example 1 is prepared according to the operation method described below.

[0068]

[0069] Diamond particles manufactured by Element Six Ltd. with an average particle diameter of 25 μm were dispersed in a nickel plating solution having a composition shown in Table 1 below so that the dispersion amount was 50 g / liter. Set the current density to 8A / dm 2 Then, a plating treatment was performed for 300 minutes to obtain a composite plating film having a predetermined total plating film thickness of 500 μm. During the formation of the composite electroplating film, the stirring speed is gradually changed from 500rpm to 150rpm, so that the eutectoid density of the diamond particles is gradually increased from the substrate surface side to the film surface side from 0vol...

Embodiment 2

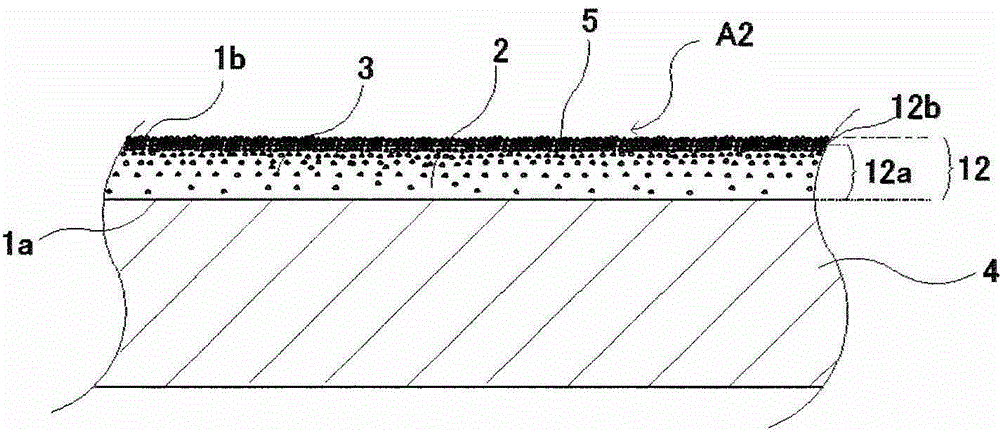

[0073] use Figure 7 The electroplating device shown (the anode material is an electrolytic copper plate) uses a stainless steel plate (20mm×20mm×0.5mm) as a base material, and the heat dissipation material of Example 2 is produced according to the operation method described below.

[0074]

[0075] Diamond particles with an average particle diameter of 25 μm manufactured by Element Six Ltd. were dispersed in a copper electroplating solution having a composition shown in Table 2 below so that the dispersion amount was 50 g / liter. The current density was set at 0.1-6A / dm2 and electroplating was performed for 540 minutes to obtain a composite electroplating film with a predetermined total electroplating film thickness of 500 μm. During the formation of the composite electroplating film, the stirring speed is gradually changed from 600rpm to 50rpm, so that the eutectoid density of the diamond particles is gradually increased from the substrate surface side to the film surface s...

Embodiment 3

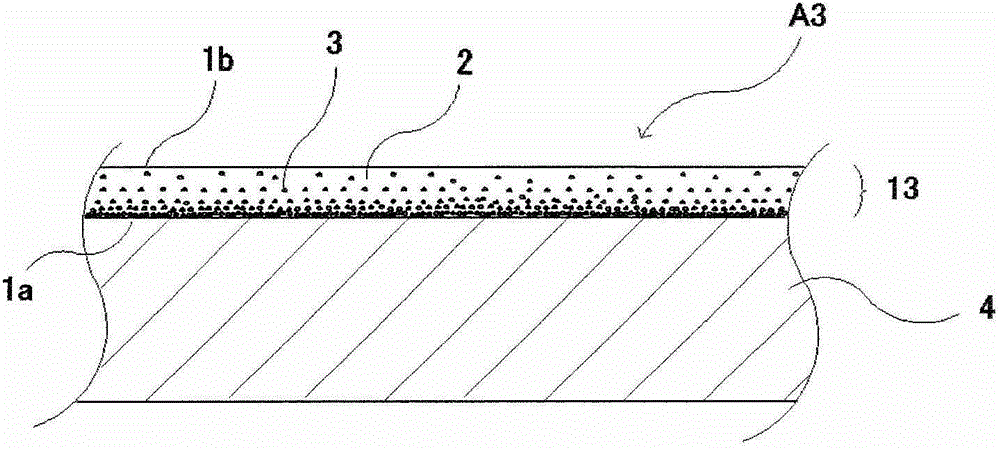

[0079] use Figure 7 The electroplating device shown (the anode material is an electrolytic nickel plate) uses a stainless steel plate (20mm×20mm×0.5mm) as a base material, and the heat dissipation material of Example 3 is prepared according to the following operation method.

[0080] Diamond particles with an average particle diameter of 25 μm manufactured by Element Six Ltd were dispersed in a nickel plating solution having a composition shown in Table 3 below so that the dispersion amount was 50 g / liter. Set the current density to 8A / dm 2 Then, a plating treatment was performed for 290 minutes to obtain a composite plating film having a predetermined plating film thickness of 490 μm. During the formation of the composite electroplating film, the stirring speed is gradually changed from 500rpm to 150rpm, so that the eutectoid density of the diamond particles gradually increases from 0vol% to 35vol% from the surface side of the substrate to the surface side of the film. Grad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com