Heat storage heat insulation knitted fabric

A technology for knitted fabrics and heat storage, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve problems such as poor tear resistance, airtightness, affecting wearing comfort and heat preservation effect, and achieve strong heat storage and warmth preservation Function, comfortable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

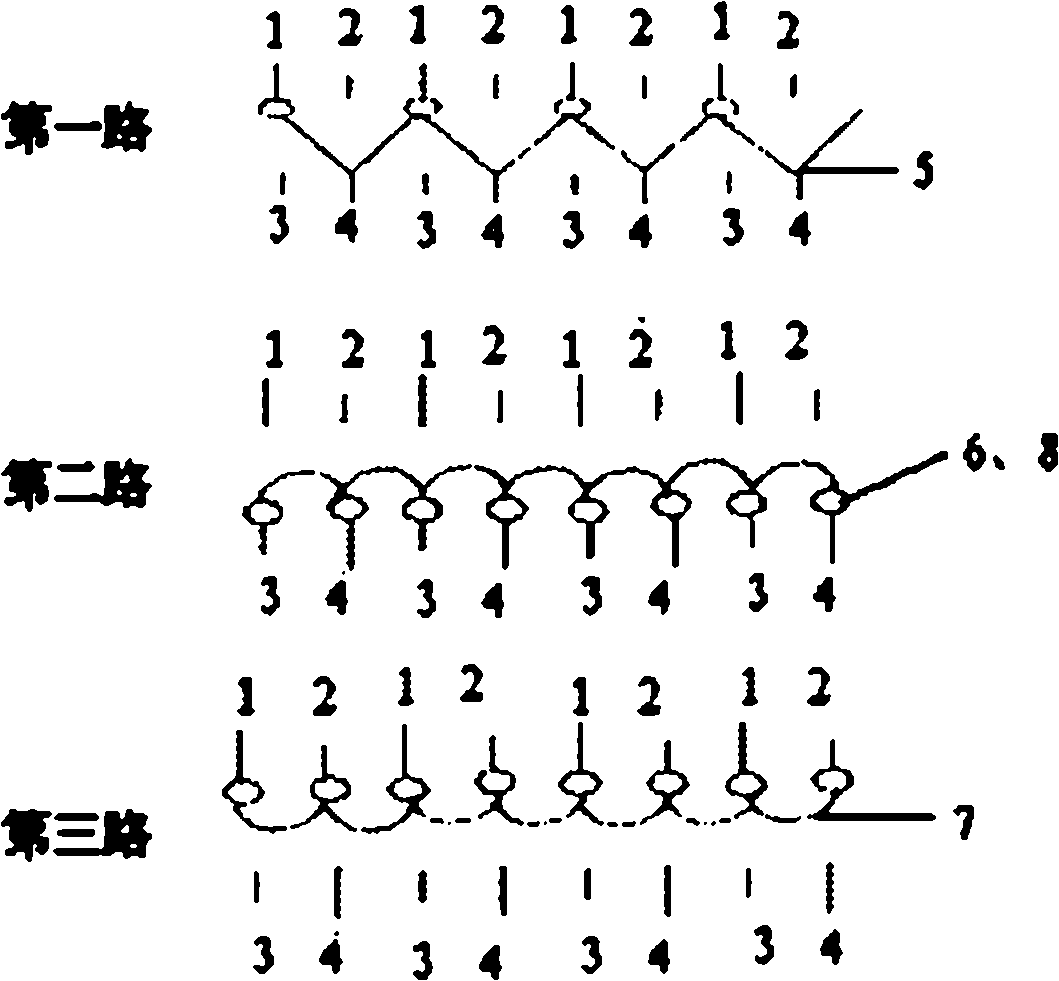

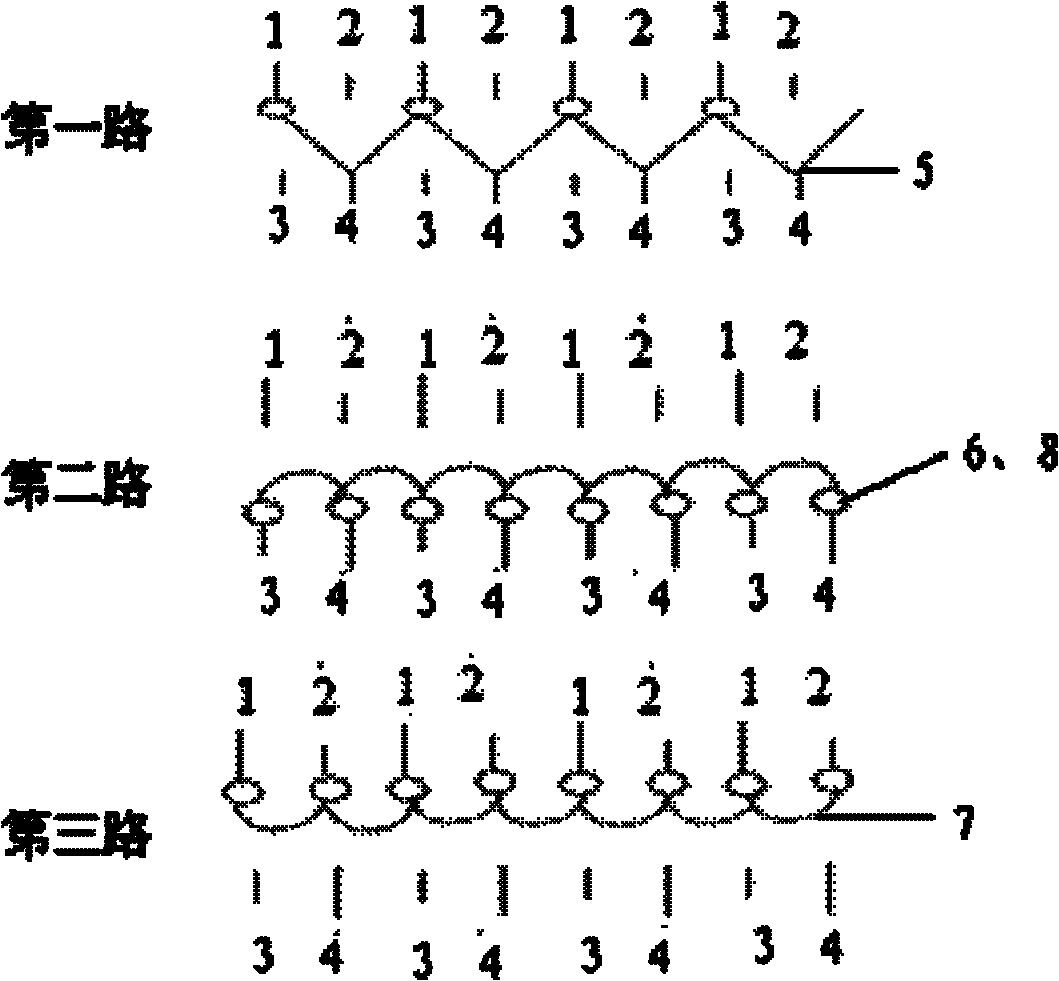

[0013] The present invention will be further described below in conjunction with the specific drawings.

[0014] The heat storage type thermal insulation knitted fabric of the present invention is knitted on a weft knitting machine, the weft knitting machine includes a dial knitting needle and a needle cylinder knitting needle, and the dial knitting needle includes the first high needle 1 and The first low needle 2, the cylinder knitting needle includes a second high needle 4 and a second low needle 3 arranged at intervals;

[0015] The fabric is woven using the following steps:

[0016] In the first way, the polyester fiber yarn 5 is fed into the yarn, forming a loop with the first high needle 1 of the dial knitting needle in the weft knitting machine, forming a floating thread with the first low needle 2, and forming a floating thread with the second low needle 3 of the cylinder knitting needle Form a floating line, forming a circle with the second high and low 4;

[0017]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com