Ring embedding or glue injecting sealing method for rigid touch surface channel

A channel and glue injection technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of short-term, inconvenient, and indirect sealing methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

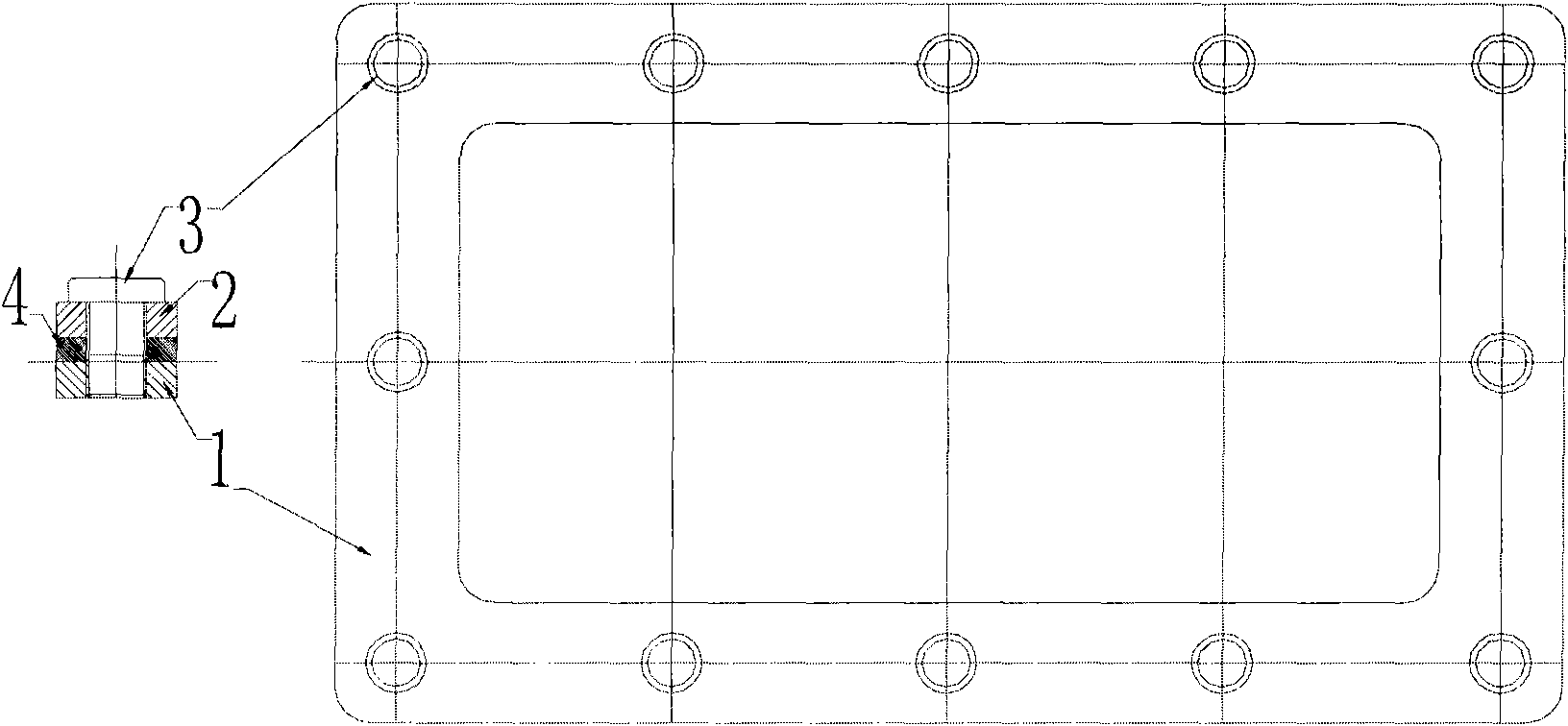

[0021] like figure 1 As shown, the traditional sealing method is achieved by placing a traditional gasket 4 between the rigid body 1 and the cover plate 2 and pressing it with the bolt 3 . Since the entire gasket is placed between the rigid body 1 and the cover plate 2 through all the bolts, after compression, what can be closed is only around the bolts and along the contact surface, and cannot form a closed-loop sealing system. When subjected to changes in temperature, humidity and working environment and pressure conditions, liquid or gas can seep out through thread gaps and other convex and concave gaps.

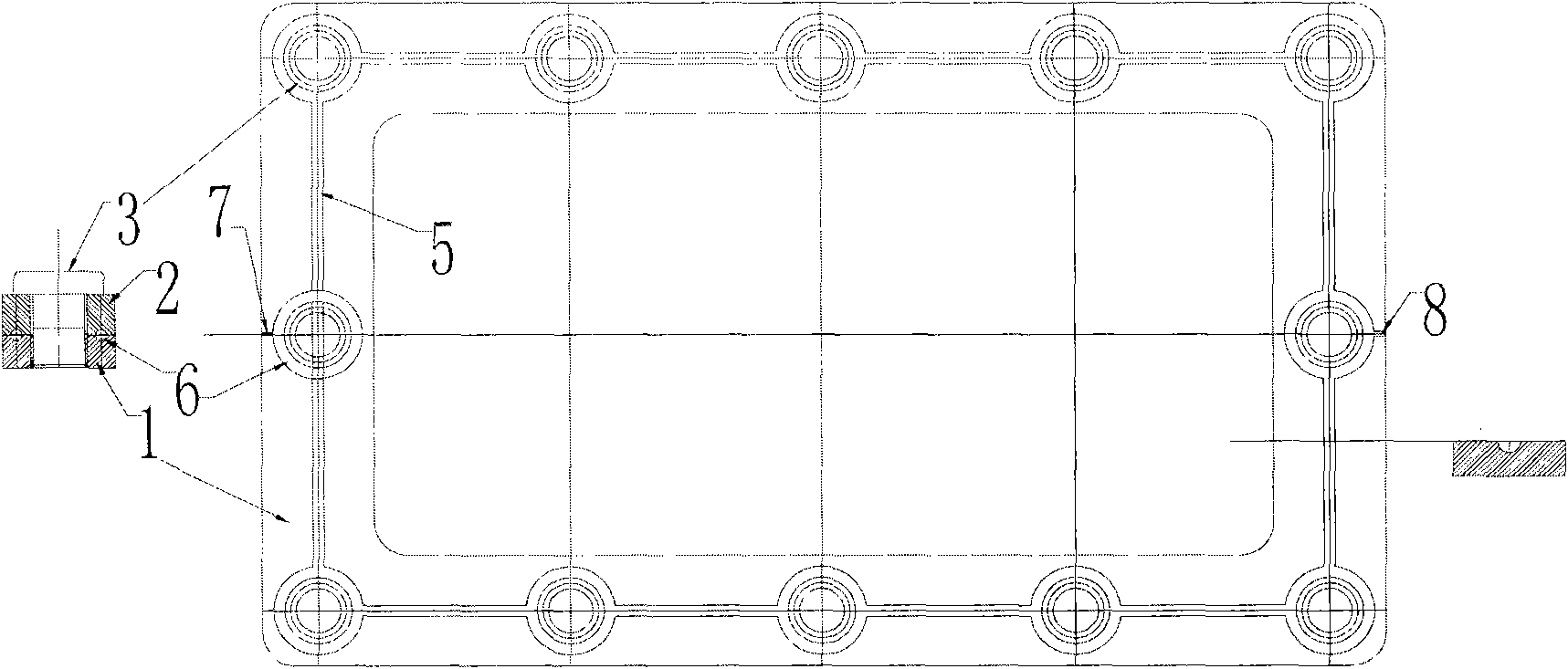

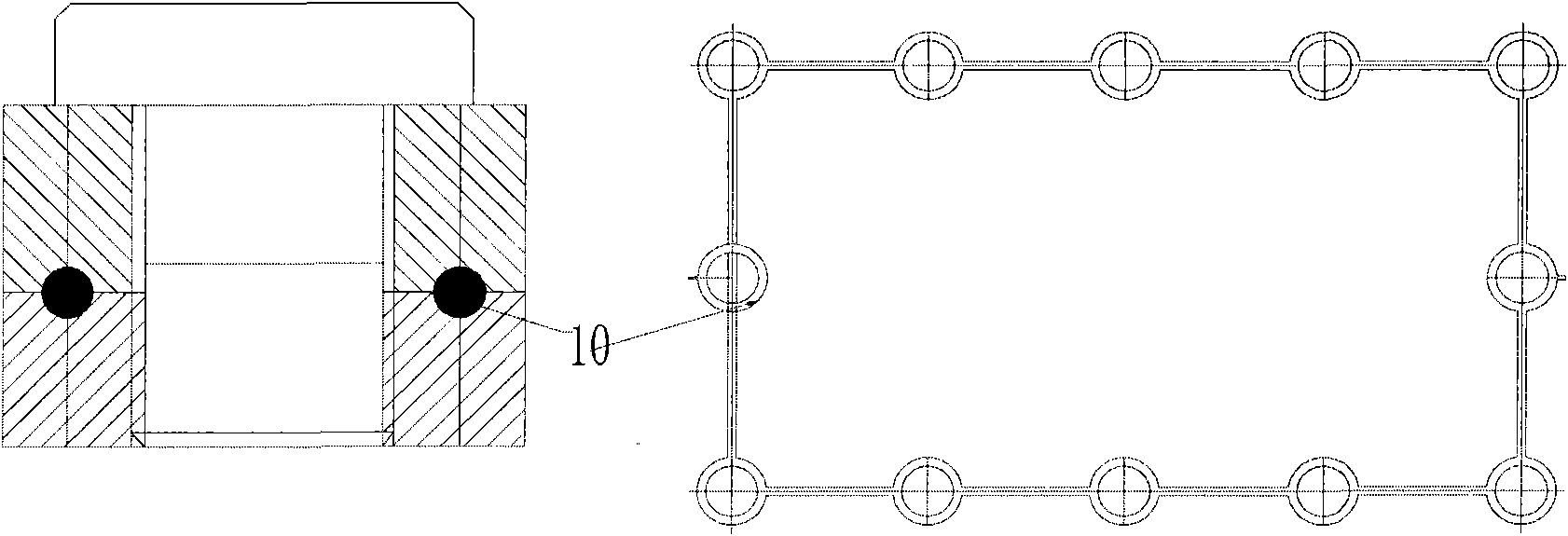

[0022] Rigid contact channel inserts or injection seals, such as figure 2 As shown, the structure is that the same number of annular semicircular passages 6 encircling the fastening bolts and the straight semicircular passages 5 connected therewith are arranged on the contact surfaces of the rigid body 1 and the cover plate 2, forming a circular passage and A closed-lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com