Leveling gauge

A spirit level and leveling technology, which is applied in the field of spirit levels, can solve problems such as complex structure, high price, and poor efficiency of spirit levels, and achieve the effect of simple structure, cheap structure, and high-efficiency adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

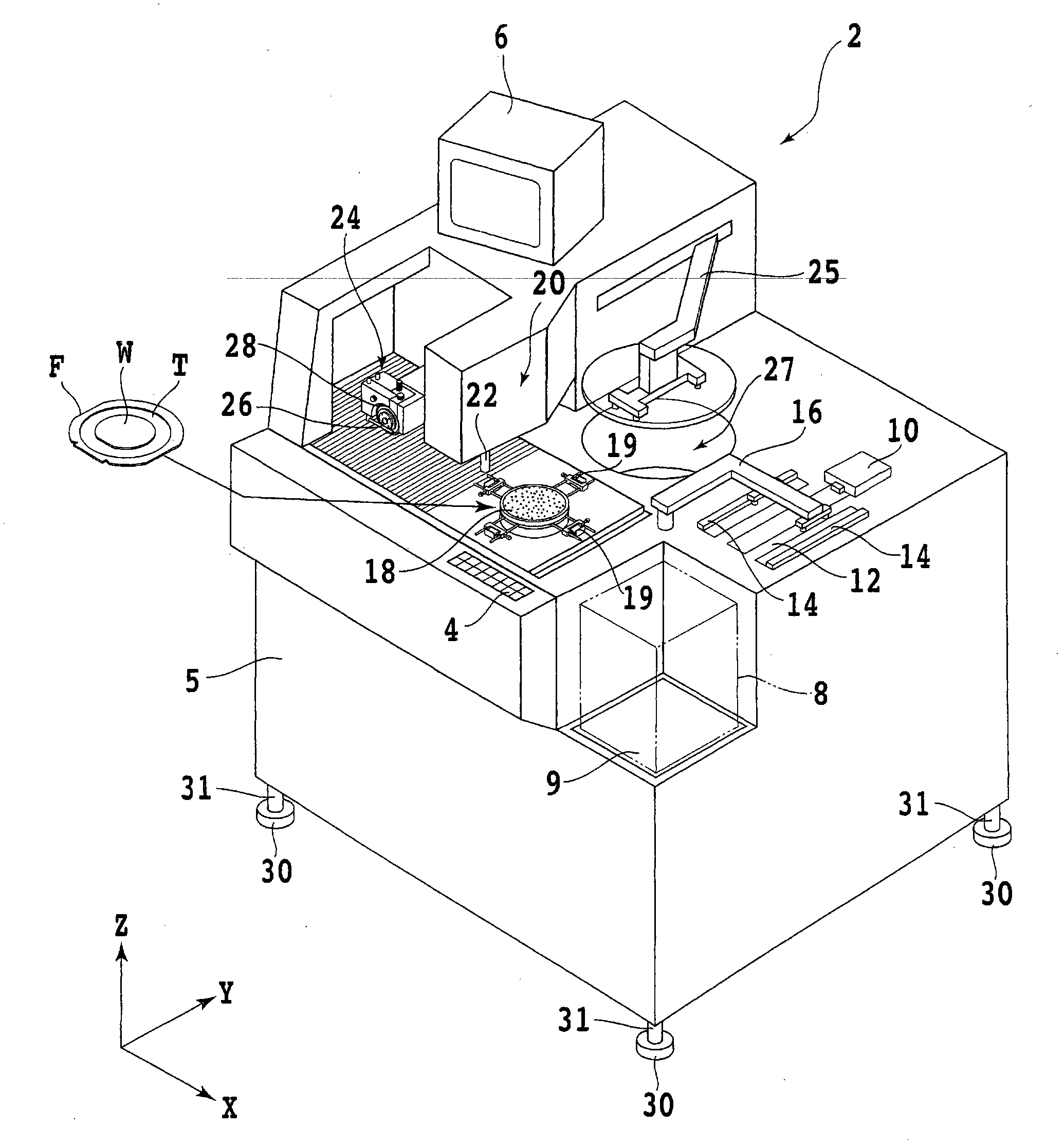

[0022] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings. figure 1 The appearance of the cutting device 2 to which the spirit level of the present invention can be applied at the time of installation is shown, and the cutting device 2 is capable of dicing a semiconductor wafer and dividing it into individual chips (devices).

[0023] On the front surface side of the cutting device 2, an operation member 4 is provided for the operator to input instructions to the device such as machining conditions. A display member 6 such as a CRT (Cathode Ray Tube) for displaying a guide screen for the operator or an image captured by an imaging member described later is provided on the upper part of the apparatus.

[0024] The wafer W is attached to a dicing tape T which is an adhesive tape, and the outer peripheral edge portion of the dicing tape T is attached to the ring-shaped frame F. As shown in FIG. Thereby, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com