Gas pressure regulator and gas pressure regulation method

A gas pressure and regulator technology, used in the measurement of fluid pressure, fluid pressure control without auxiliary power, instruments, etc., can solve the problems of large temperature influence, high dynamic sealing requirements, excessive mechanical energy, etc. The effect of high control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

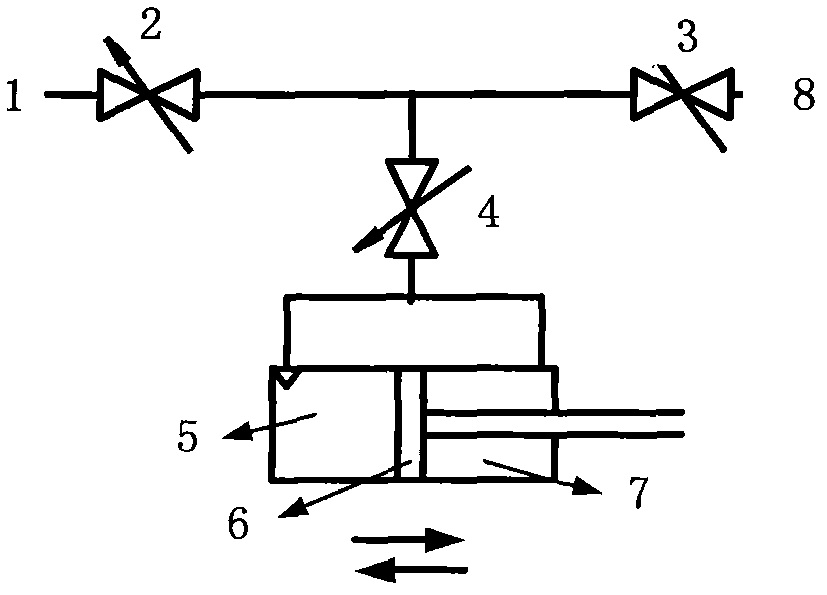

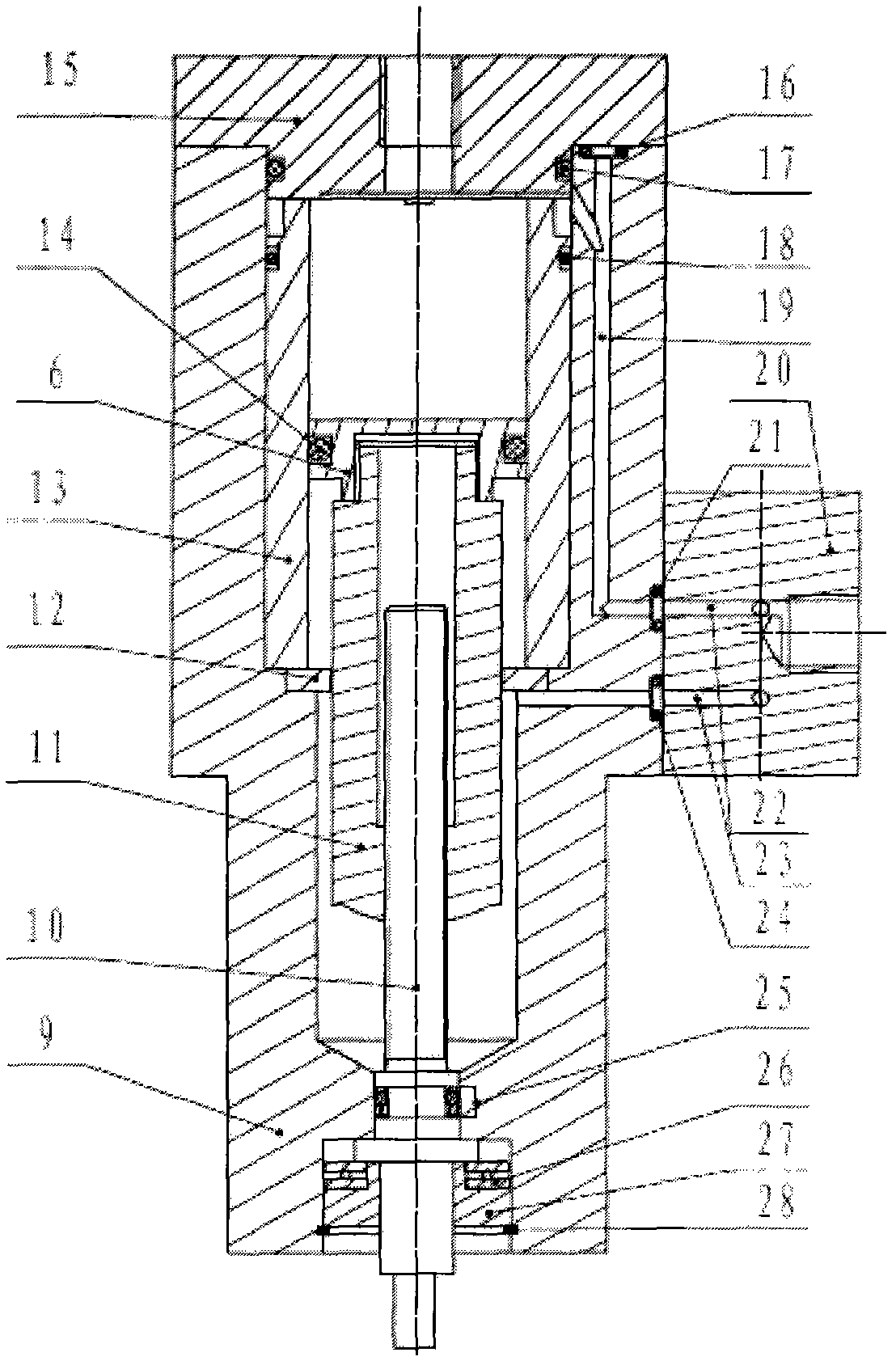

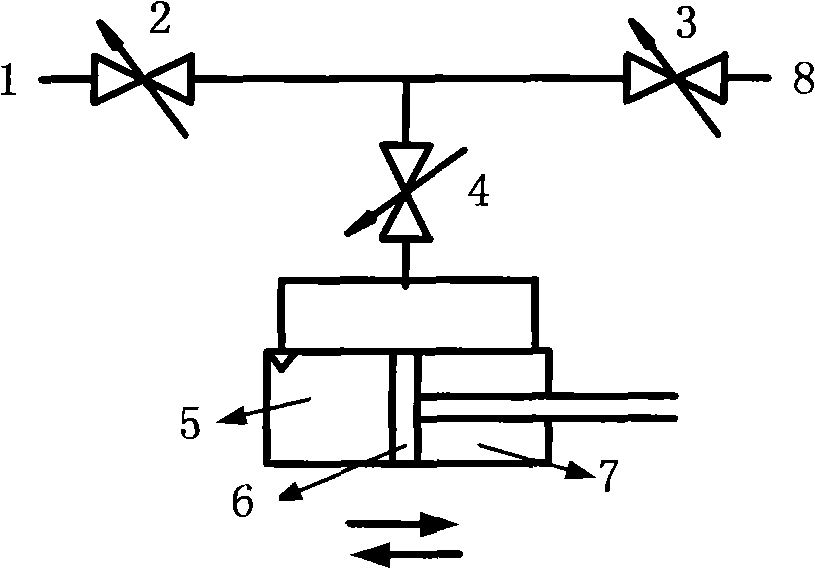

[0024] combine figure 1 , figure 2 The present invention is described in detail below.

[0025] The gas pressure regulator includes five parts: the regulator main body 9, the transmission part, the piston assembly, the combined valve and the seal. The top end of the regulator main body 9 is provided with an end cover 15; the piston cylinder 13 is placed in the cavity of the regulator main body 9, and the piston 6 Located in the piston barrel 13, the nut actuator 11 is connected to the piston 6, one end of the lead screw 10 is connected to the nut actuator 11, the other end of the lead screw 10 is provided with a limit step, and the plane thrust bearing 25, the bearing gasket 26 and 27 sets of retaining ring sleeves Connect to the lead screw 10, and fix the lead screw 10 on the regulator main body 9; the regulator main body 9 corresponds to the front chamber 5 and rear chamber 7 limit positions of the piston 6 with two air holes 22, 23, two air holes 22 , 23 are connected th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com