Roller heating mechanism

A heating mechanism and heating roller technology, applied in induction heating, induction heating devices and other directions, can solve the problems of high heating cost, loss of economy, difficult temperature control, etc., and achieve the effect of ensuring heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

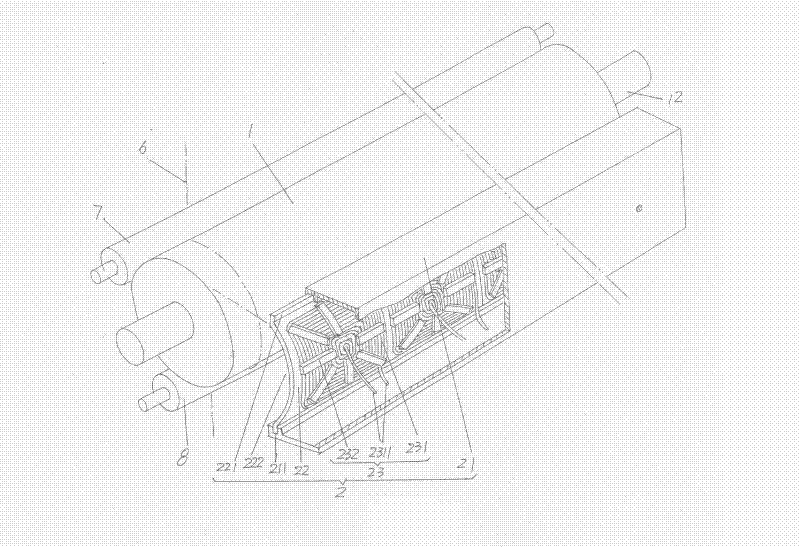

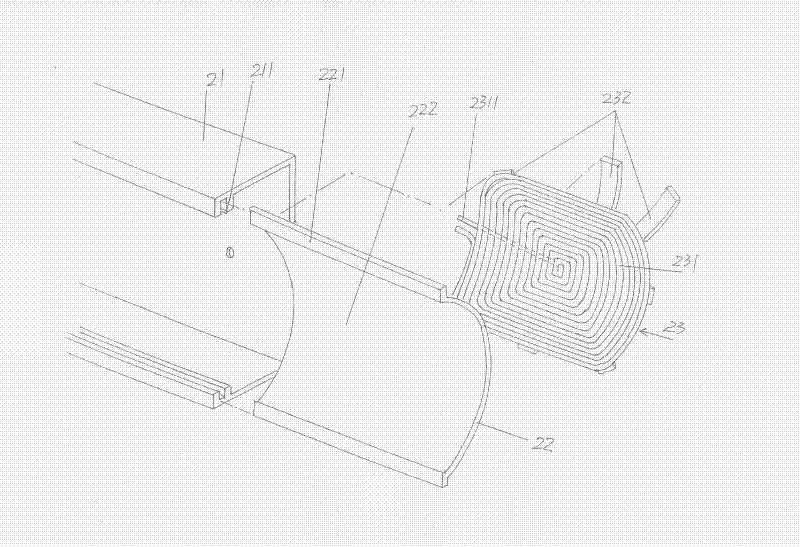

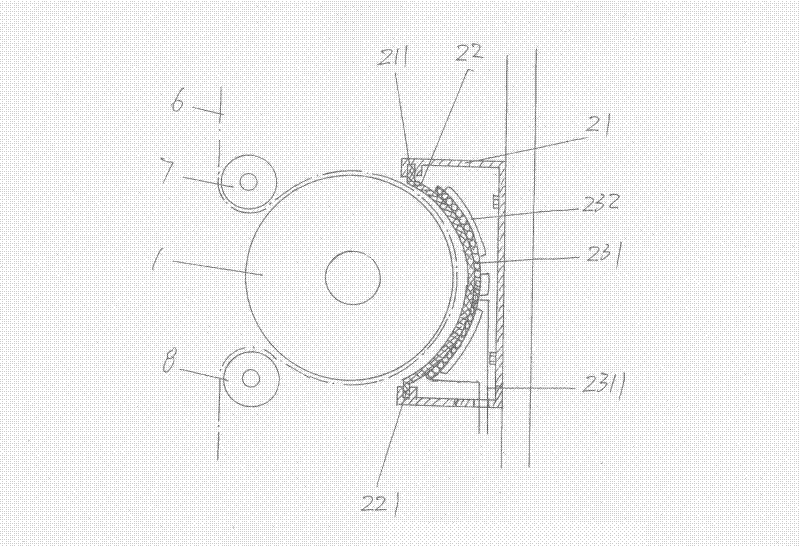

[0019] please see Figure 1 to Figure 4 , a heating roller body 1 made of iron is provided. If the material of the heating roller body 1 is aluminum or copper, it is not suitable for the solution of the present invention. A thermal energy supply device 2 is arranged on one side of the length direction of the heating roller body 1, and the thermal energy supply device 2 includes a support 21, a plurality of tile plates 22 and electromagnetic coils 23 equal to the number of the tile plates 22, and the support 21 faces One side of the heating roller body 1 is open, and a tile plate insertion groove 211 is formed (opened) on the upper and lower parts of the side, and on both sides of the length direction of the tile plate 22 ( figure 1 The shown upper side and the lower side) respectively form an inserting rib 221 , and the inserting rib 221 is mated with the tile inserting groove 211 . The tile 22 is made of ceramics, and the cavity 222 of the tile 22 faces the heating roller bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com