Solar component junction box suitable for automated assembly

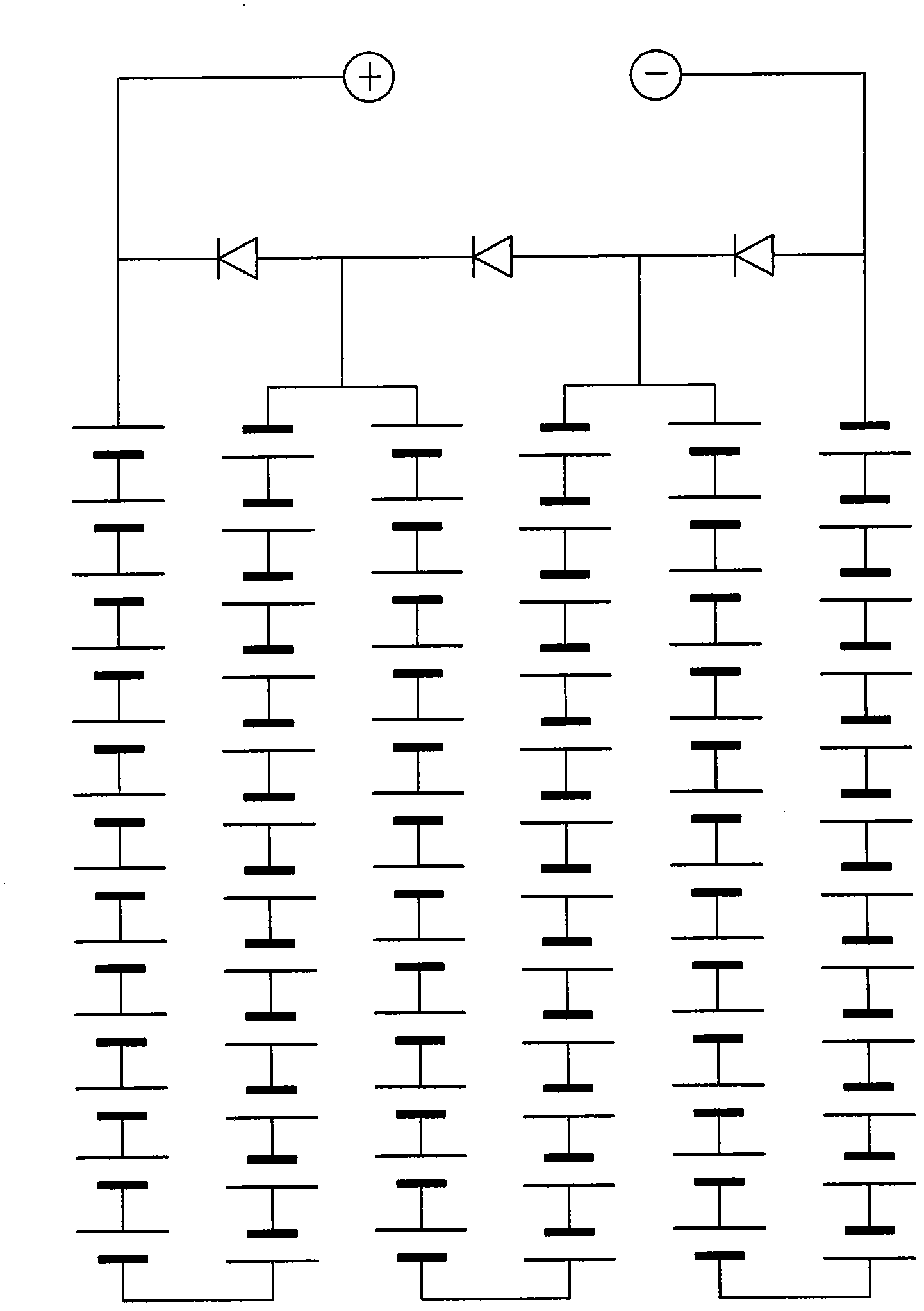

A solar module and junction box technology, applied in electrical components, photovoltaic modules, photovoltaic power generation, etc., can solve the problems of increasing the complexity factor of automatic assembly lines, the impact of assembly line reliability, and increasing the cost of automatic assembly lines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

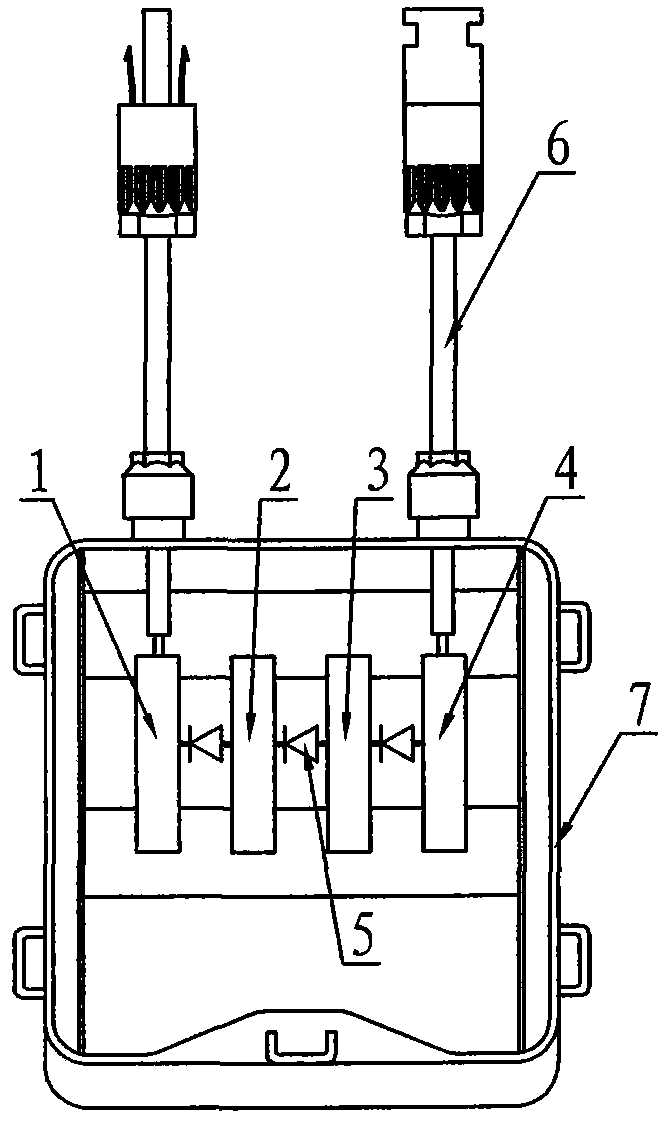

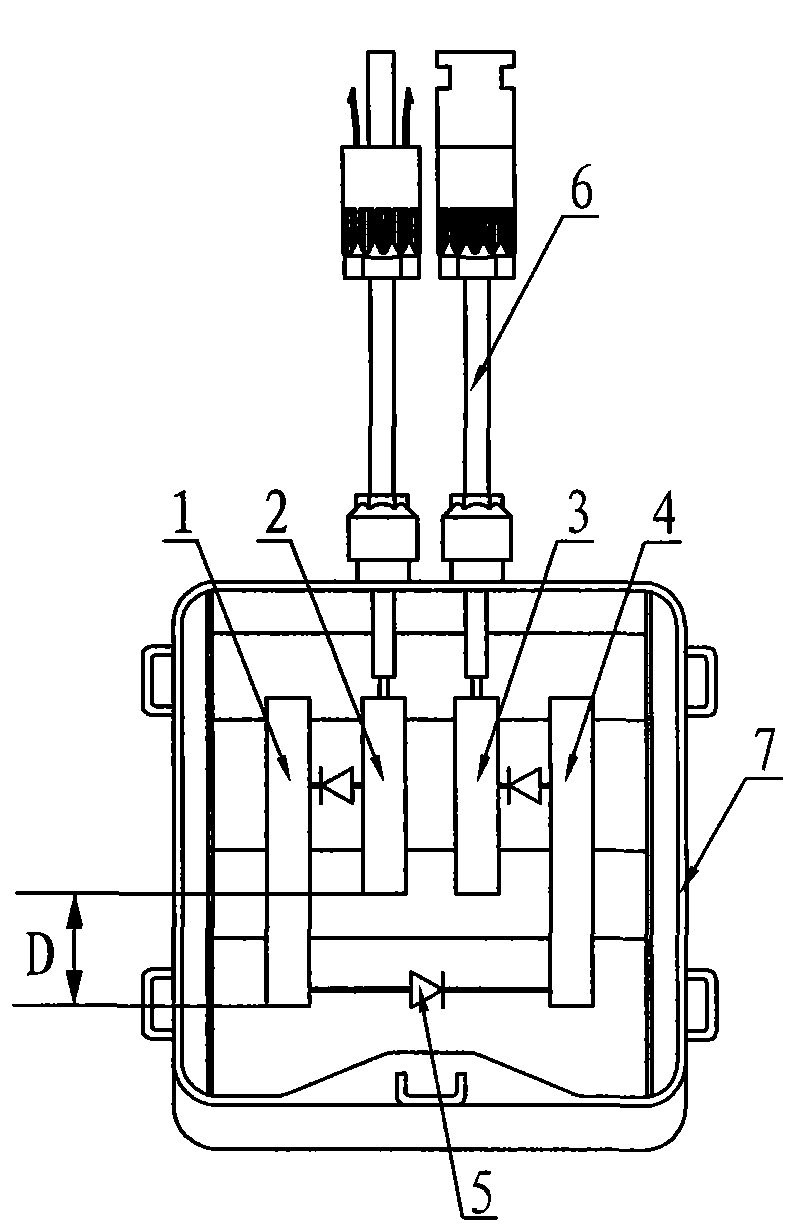

[0017] The solar module junction box suitable for automatic assembly, such as image 3 ~ Figure 4 As shown, it includes No. 1 metal sheet 1, No. 2 metal sheet 2, No. 3 metal sheet 3, No. 4 metal sheet 4, diode 5, output cable 6 and junction box body 7, No. 1 metal sheet 1, No. 2 metal sheet Metal sheet 2, No. 3 metal sheet 3 and No. 4 metal sheet 4 are distributed in the junction box body 7 in parallel intervals from left to right, and the upper ends are flush. The lengths of No. 1 metal sheet 1 and No. 4 metal sheet 4 are the same. No. 2 metal piece 2 and No. 3 metal piece 3 have the same length, the difference D between No. 1 metal piece 1 and No. 2 metal piece 2 is 8 mm, and the L-shaped metal busbar A5 and the straight metal busbar A6 are in the horizontal direction The upper height difference F is 10 mm, a diode 5 is connected between the second metal sheet 2 and the first metal sheet 1, and the two pins of the diode 5 are respectively welded in the middle of the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com