Automatic coffee machine

A coffee machine, automatic technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of increased cost and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

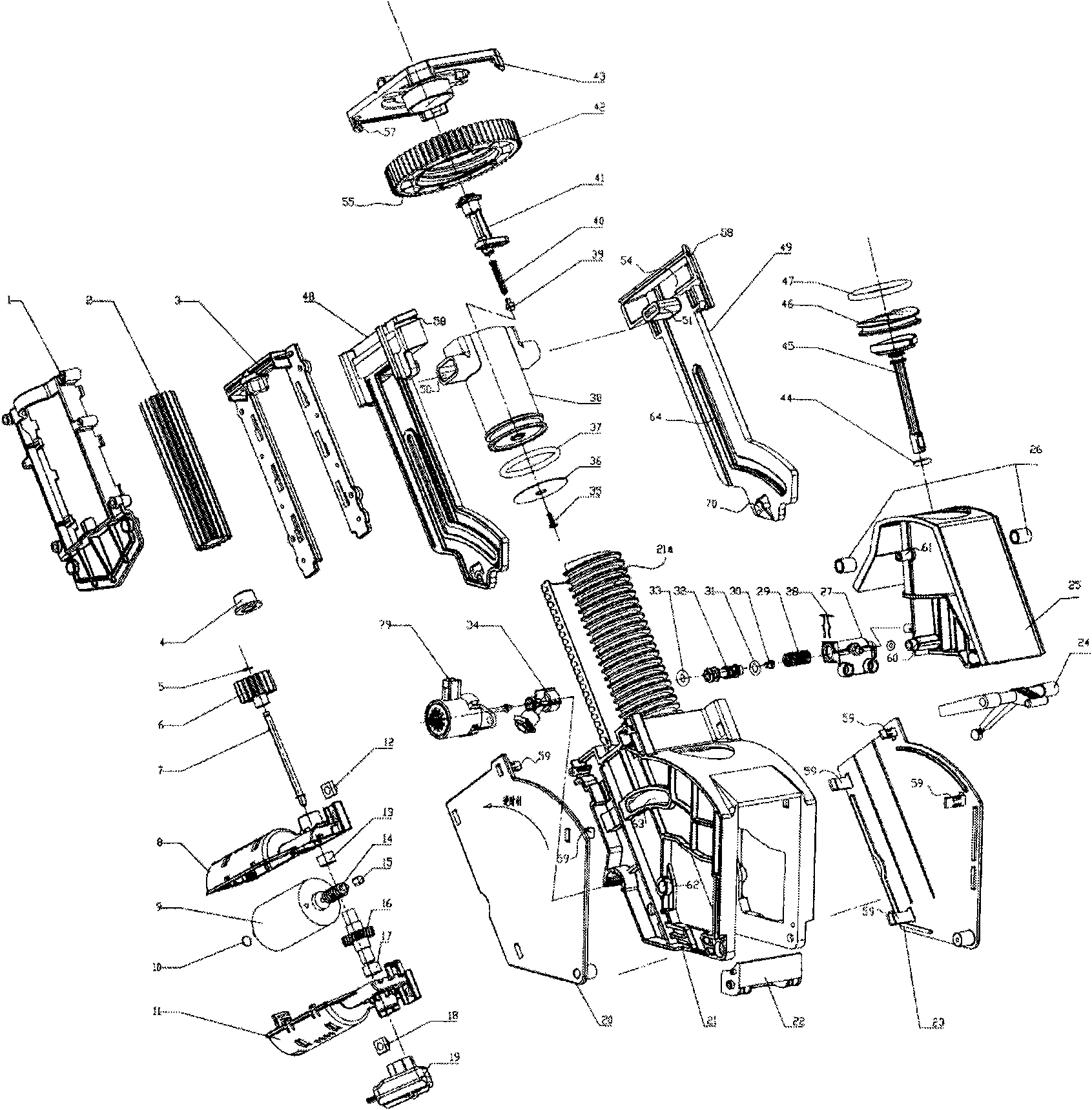

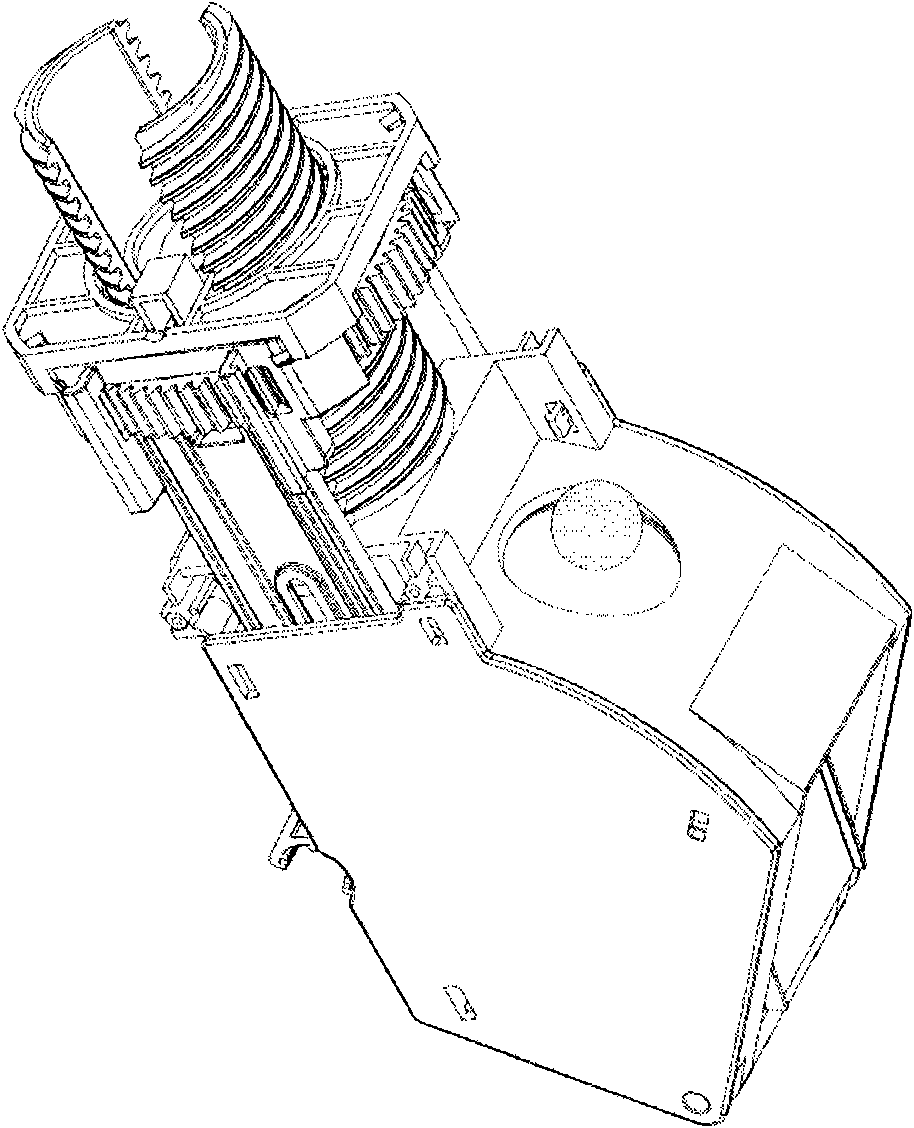

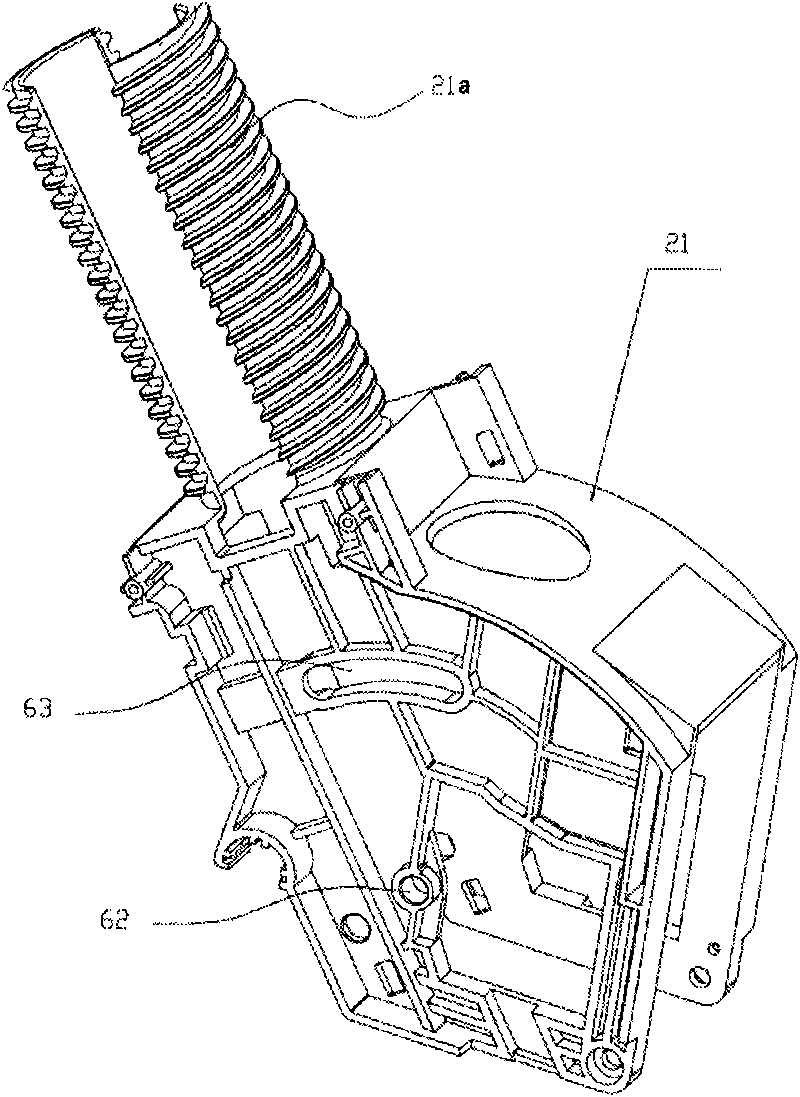

[0031] See attached figure 1 to attach Figure 15, an automatic coffee machine, including a brewing device as a core working unit, the brewing device includes a main frame 21 and a coffee box 25 accommodated therein, a transmission motor 9 as a power source of the transmission mechanism, and the transmission mechanism The brewing mechanism, the water inlet mechanism and the water discharge mechanism driven by the stepping motor 79 are connected and driven by the transmission mechanism. The transmission mechanism includes a transmission motor 9 that is fixed between the upper transmission motor seat 8 and the lower transmission motor seat 11 . In order to prevent axial serial movement when the transmission motor 9 is working, buffer pads 10 and motor shaft sleeves 15 are respectively provided at both ends of the shaft of the transmission motor 9 . In addition, the upper copper sleeve 12 and the lower copper sleeve 18 are sleeved in the screw holes, so that when the transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com