Direct drainage toilet bowl with deodorant valve

A toilet and anti-odor technology, which is applied in flushing toilets, water supply devices, buildings, etc., can solve the problems of poor deodorant performance of direct drainage, and achieve significant water saving and good anti-odor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

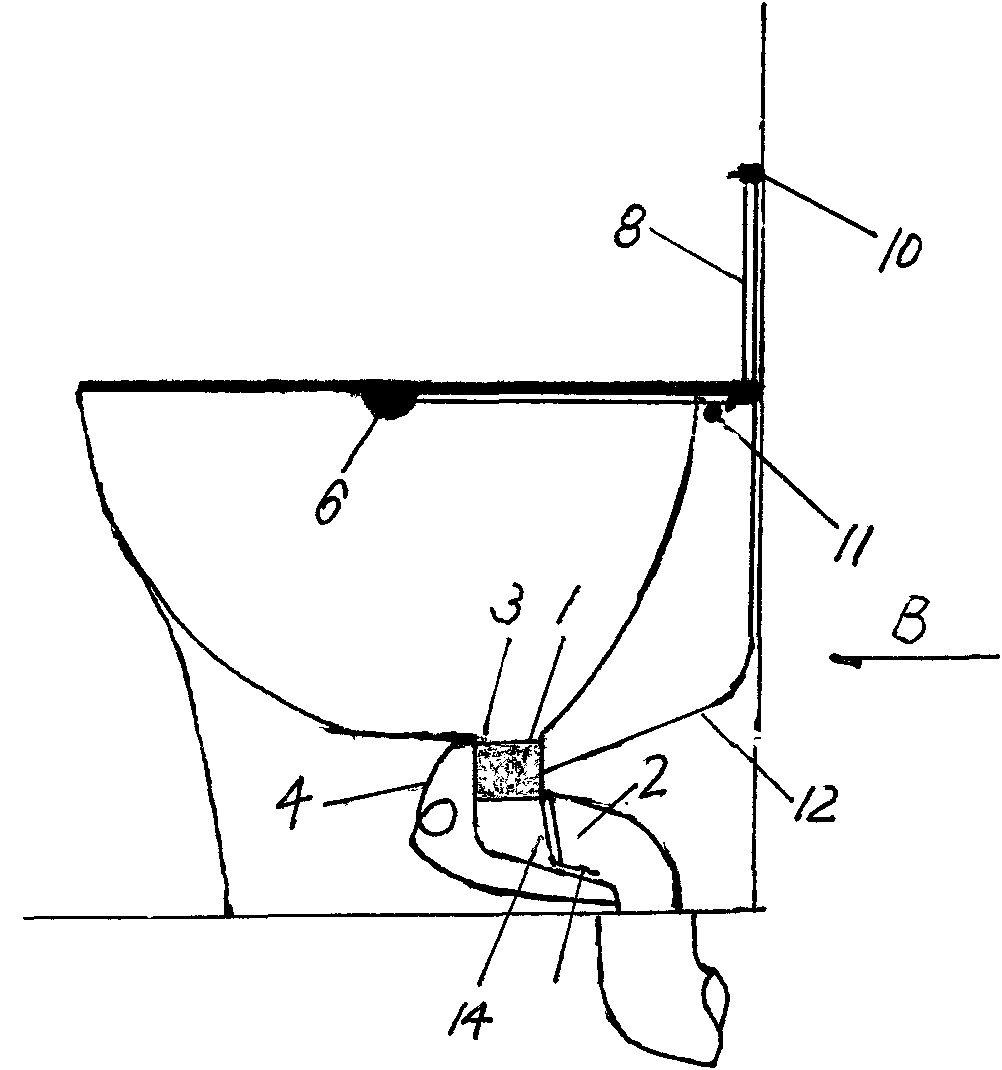

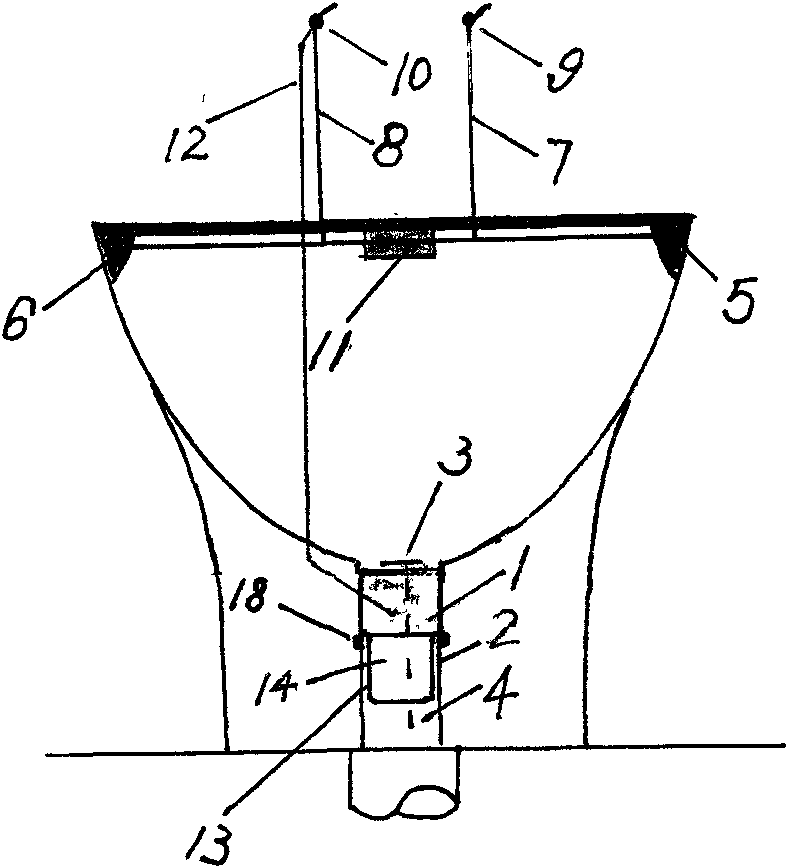

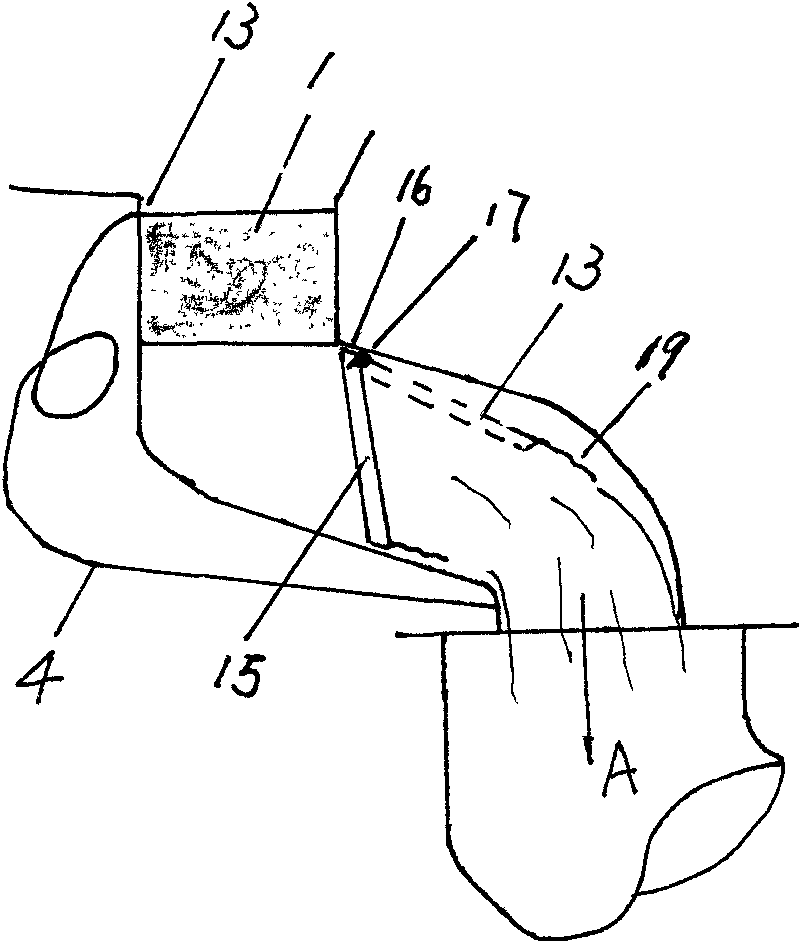

[0007] As shown in the figure, a ball valve 1 with a diameter of about 60 mm is installed at the drain outlet at the bottom of the bedpan, and an anti-odor valve 2 is connected under it to form a straight passage for defecation. The basin wall of the ball valve upper mouth has a horizontal strip opening 3, and the back is connected with the urination capillary 4 with the water trap and passed into the deodorizing valve. Porous nozzle 5,6 is established along bedpan pan, is directly supplied with tap water by pipe 7,8, is controlled the switch of water by valve 9,10 being installed on the wall. A check valve 11 is connected between the pipes 7 and 8, and water can only flow from the pipe 8 to the pipe 7. When the valve 9 is opened, the porous nozzle 5 sprays water; and when the valve 10 is opened, the porous nozzle 5, 6 sprays water. When urinating, the ball valve 1 is in the closed state, and the urine is drained from the urinal channel with a trap. After defecation, the poro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com