Short-section temporary gob-side entry retaining method

A technology of empty entry retaining and short section, which is used in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of inconvenient safety production management, harsh working environment, manual repair, etc., so as to reduce the amount of roadway excavation and reduce the preparation time. , the effect of simplifying the technical difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

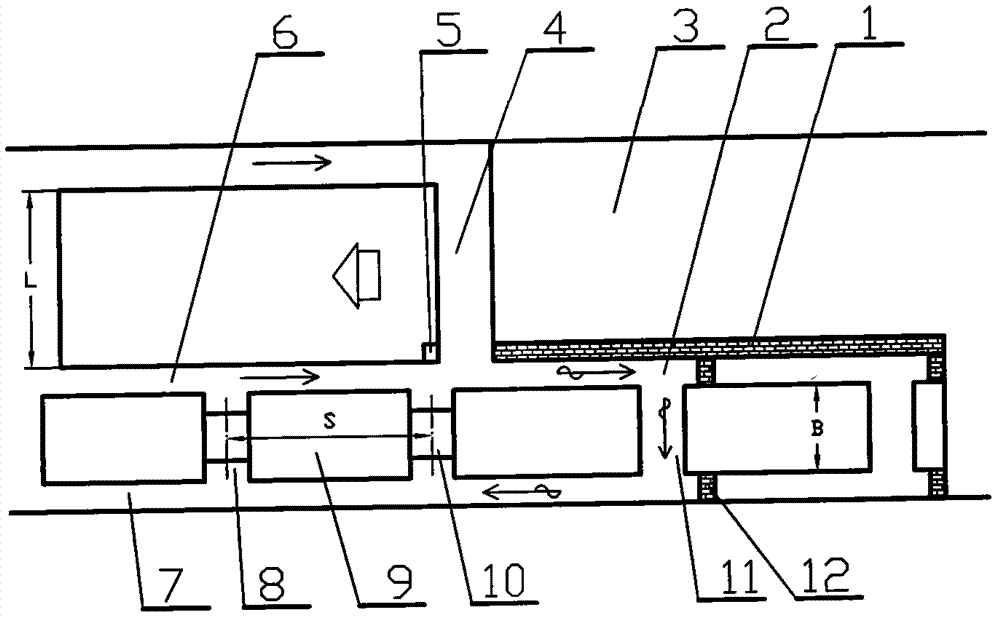

[0020] in the attached figure 1 In the mining face, there are air inlet lanes 6 and air return lanes 7 arranged on the side of the roadway to be retained in the mining face, and coal pillars 9 are reserved between the air inlet roadway 6 and the air return roadway 7, and are arranged at intervals in the extension direction of the roadway A connection lane 8 connecting the air inlet lane 6 and the return air lane 7, the middle of the linkage lane 8 is provided with a sealed partition wall 10, and the connection lane 8 close to the working face opens the closed partition wall 10 to form a return air connection lane 11.

[0021] The temporary gob-side entry retaining method for this short section is as follows:

[0022] (1) Prefabricate high-strength concrete blocks on the ground for use, and the blocks are divided into basic blocks and height-adjusting blocks according to size;

[0023] (2) Open a rectangular gap 5 on the coal wall of the working face 4 on the side of the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com