Buoyancy force control switch for set water level

A technology for controlling switch and buoyancy, applied in mechanical equipment, valve details, engine components, etc., can solve the problems of inflexible installation position, low water level control accuracy, low reliability, etc., to achieve high water level control accuracy, long stroke, and reliable. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

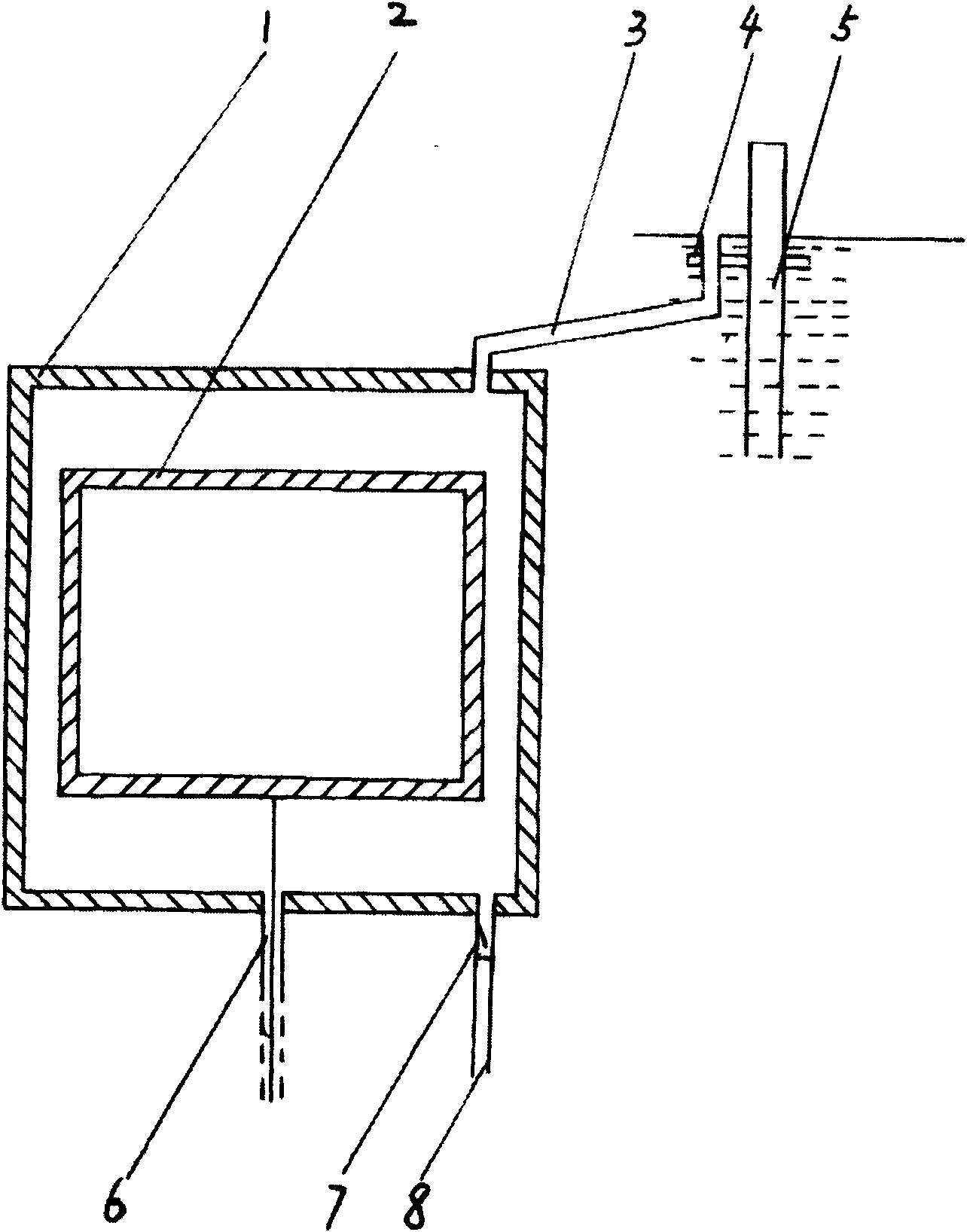

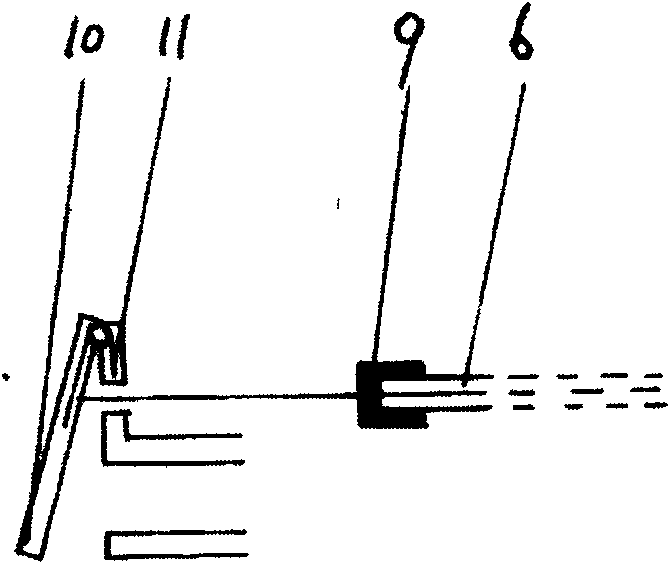

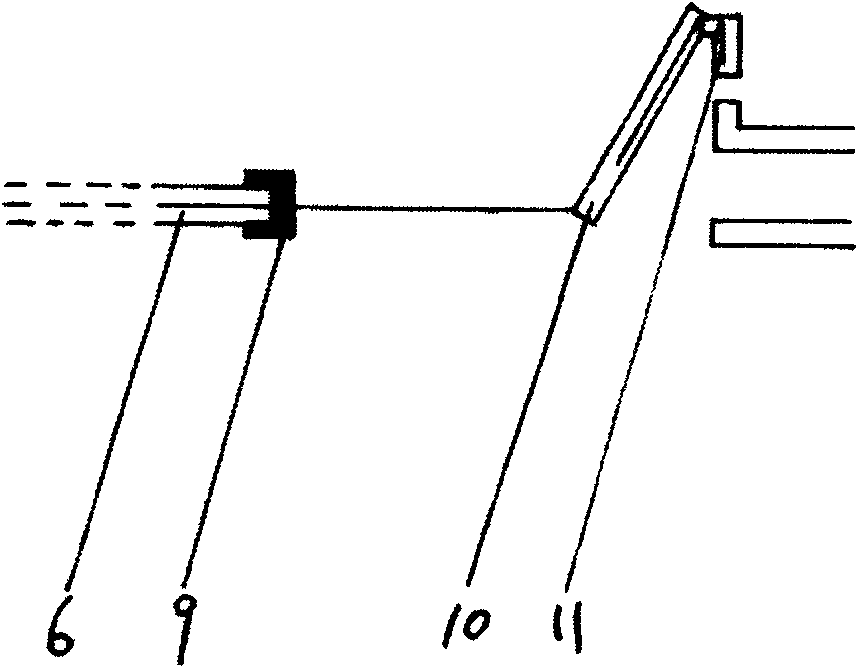

[0011] In the accompanying drawings, the outer sealed container (1) is equipped with a floating body (2), and the outer sealed container (1) is connected with a water inlet pipe (3), a one-way water outlet valve (7), and the mouth of the water inlet pipe (3) is fixed. On the fixing clip (4) on the lifting rod (5), the water outlet pipe (8) is connected to the one-way water outlet valve (7) at the bottom of the outer sealed container (1), and the middle part of the bottom of the outer sealed container (1) is connected with a force transmission The pipe of the pipeline (6), the end of the pipe is connected with a sealing rubber (9), the middle part of the bottom of the floating body (2) is connected with the line of the force transmission pipeline (6), and the other end of the line passes through the pipe end of the force transmission pipeline (6) The sealing rubber (9) of the head is connected to the valve cover (10) after the valve cover (10), and the return spring (11) is hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com