Method for testing load of front axle of commercial vehicle

A load test, commercial vehicle technology, applied in the vertical force and braking torque test, the longitudinal force on the front axle of commercial vehicles, and the lateral force field, can solve the problems of expensive equipment, high maintenance and repair costs, and achieve small cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

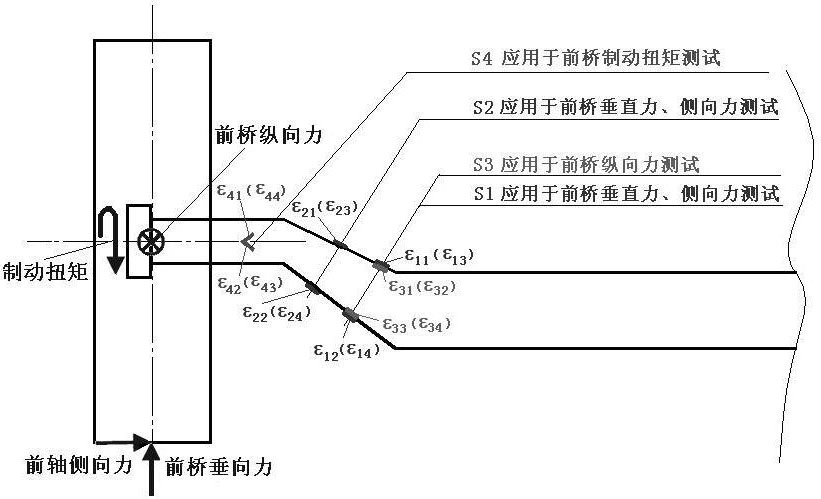

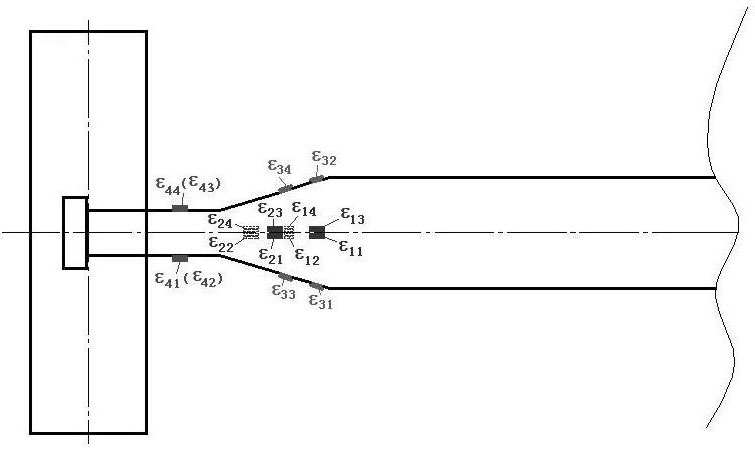

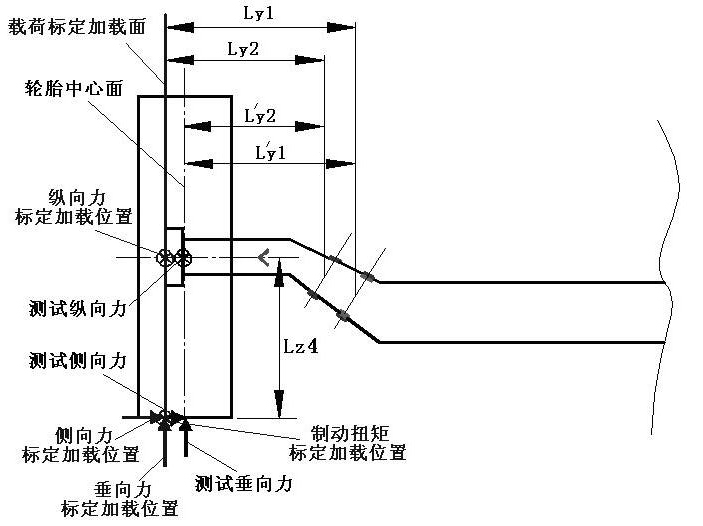

[0011] Such as figure 1 , figure 2 As shown, paste the resistance strain gauges 11, 13, 21, 23 on the left side of the front axle, and paste the resistance strain gauges 12, 14, 22, 24 on the left side of the front axle. The 1 / 4 and 3 / 4 proportions of the front side of the downward curve are attached along the axial direction of the resistance strain gauges 32, 34, and the 1 / 4 and 3 / 4 proportions of the rear side of the left downward curve of the front axle are along the axial direction. Paste the resistance strain gauges 31 and 33 respectively, and paste the resistance strain gauges 43 and 44 on the middle front side of the horizontal part of the front axle on the left side of the front axle before bending down, in the direction of ±45o to the axial direction, respectively, on the left side of the front axle Paste the resistance strain gauges 41 and 42 on the middle and rear side of the horizontal part before the front axle is bent down, in the direction of ±45o with the axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com