Device for simulating load capacity of door lock during closing of sliding door of automobile

A technology of load force and door lock, which is applied in the field of simulation devices, can solve the problems of increasing the labor force of testers, cumbersomeness, and high site requirements, and achieve the effects of shortening the research and development cycle, simplifying test steps, and facilitating test work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

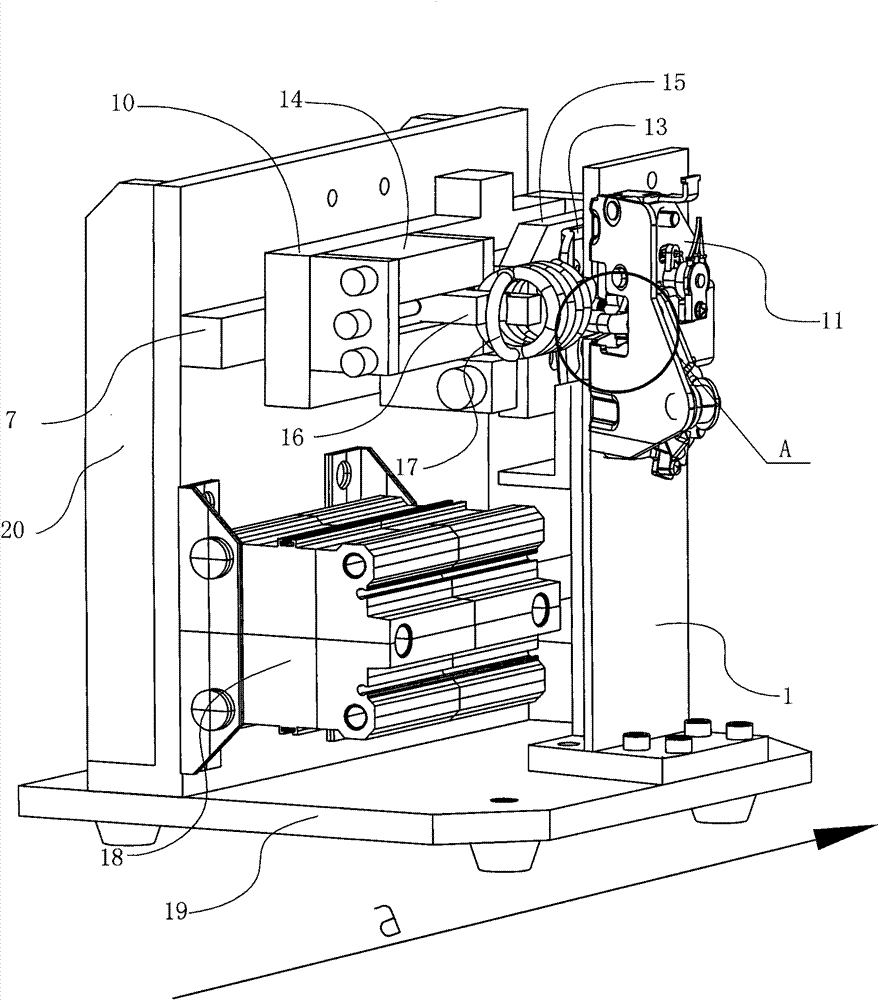

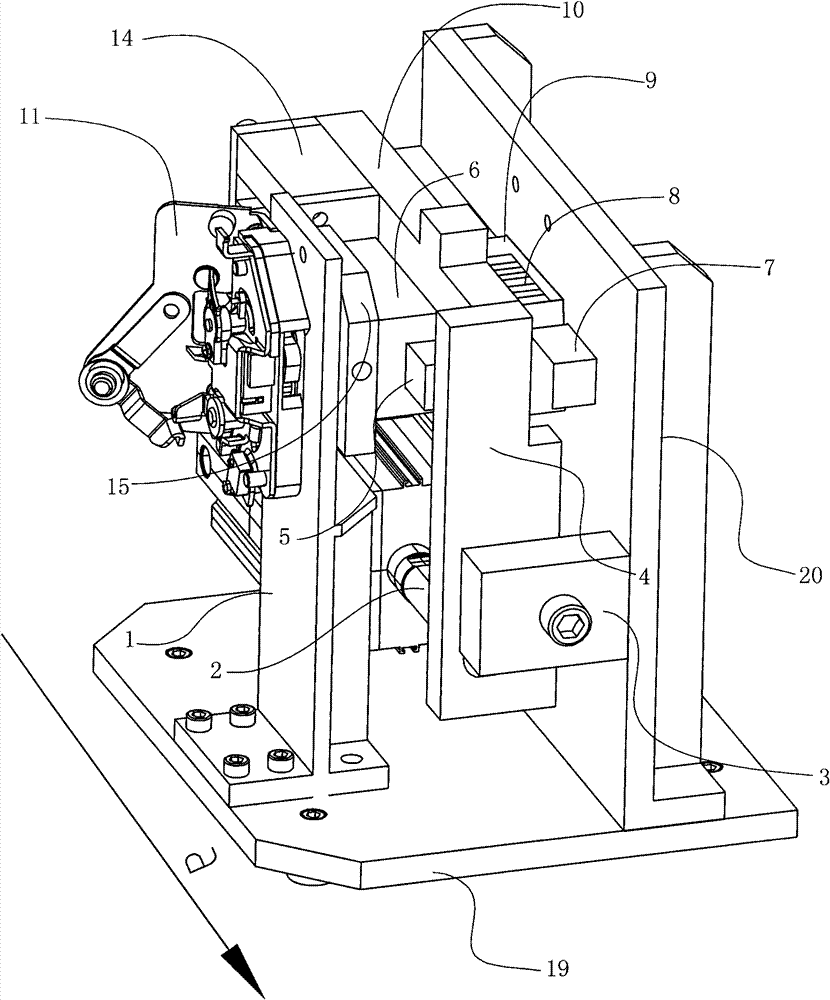

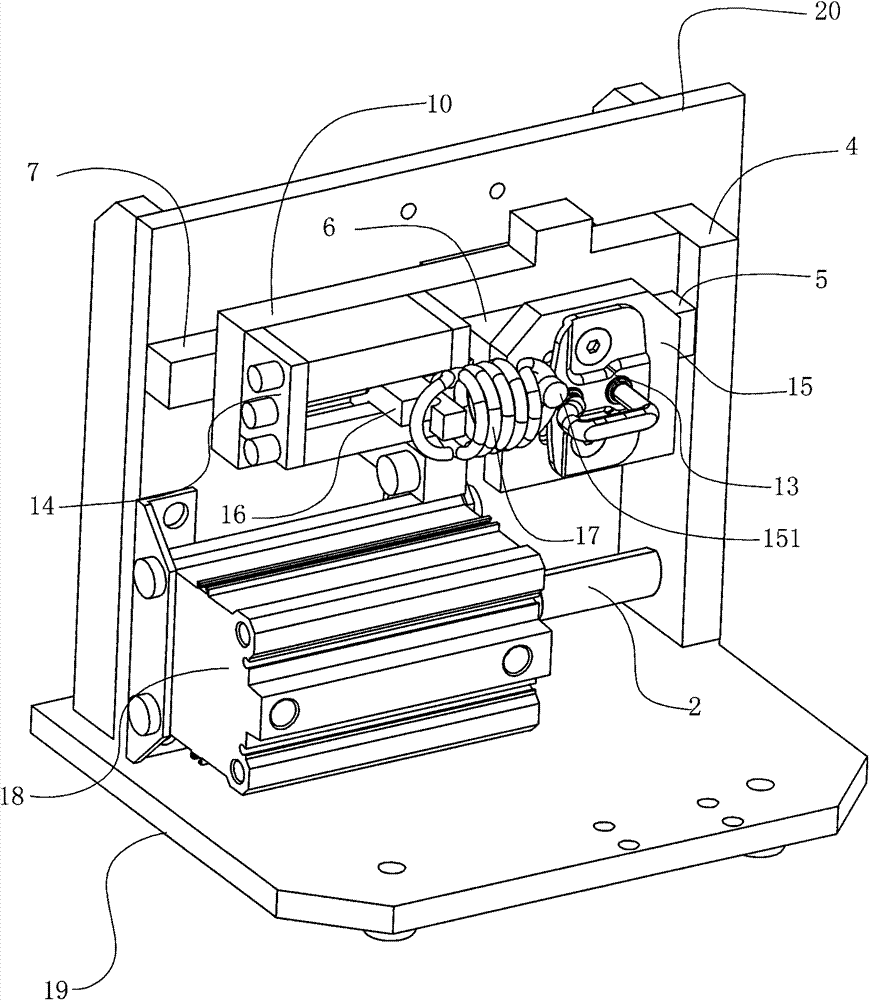

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0021] The device of the present invention for simulating the load force of the door lock when the sliding door of the automobile is closed, such as Figure 1-4 As shown, it includes a base plate 19, a door lock mounting plate 1 and a fixed mounting plate 20 vertically fixed on the base plate 19, and the door lock mounting plate 1 and the fixed mounting plate 20 are arranged in parallel at a certain distance. A transverse linear guide rail 7 is fixed on the fixed mounting plate 20 , the load mounting plate 10 is mounted on the linear guide rail 7 , and the load mounting plate 10 can move laterally on the linear guide rail 7 along the linear guide rail 7 .

[0022] One end of the load mounting plate 10 is also fixed with a vertical load transition plate 4 perpendicular to the load mounting plate 10, and the other end of the load mounting plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com