Pressure stabilizing valve for crankcase for engine

A crankcase and engine technology, applied in engine components, crankcase ventilation, machine/engine, etc., can solve the problems of slow response of crankcase pressure, high relative pressure of crankcase, oil channeling, etc., to ensure service life and reduce channeling. The effect of oil quantity and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment, the present invention is further described, but does not constitute any restriction to the present invention, anyone makes the limited number of amendments in the scope of claims of the present invention, still within the scope of claims of the present invention.

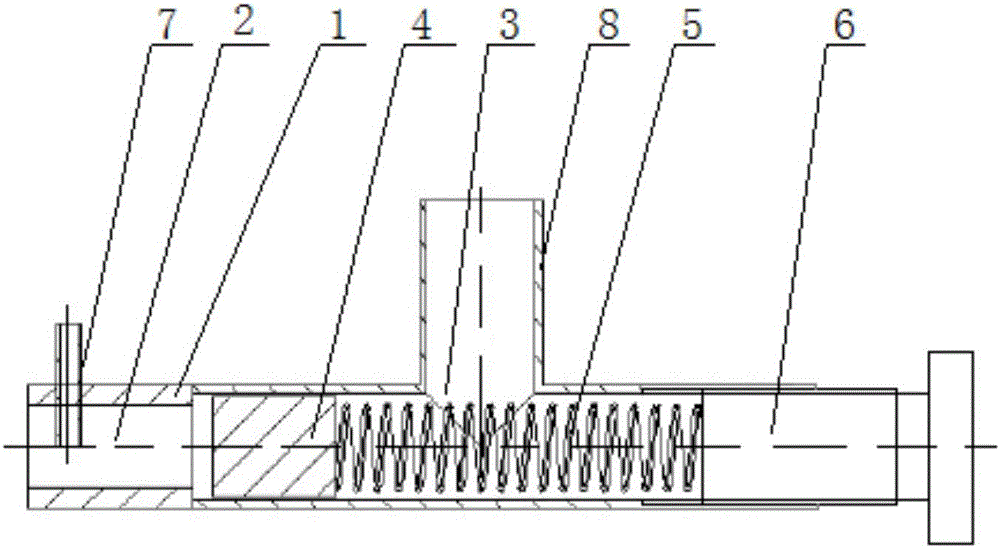

[0014] The specific embodiment of the present invention is like this: with reference to figure 1 Shown, a kind of engine crankcase pressure-stabilizing valve comprises hollow columnar valve body 1, and one end of valve body 1 is provided with the intake cavity 2 that connects engine crankcase outlet, and the other end is closed, and the side wall of valve body 1 is provided with There is an air outlet 3 connected to the oil-gas separator, and the cavity of the valve body 1 between the air inlet chamber 2 and the closed end is an adjustment chamber, and the adjustment chamber is equipped with a controllable conduction or cut-off regulator. The air pressure in the intake c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com