Vacuum cleaner

A technology for vacuum cleaners and containers, applied in the direction of vacuum cleaners, suction filters, household appliances, etc., can solve the problems of lack of stability and lack of attention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

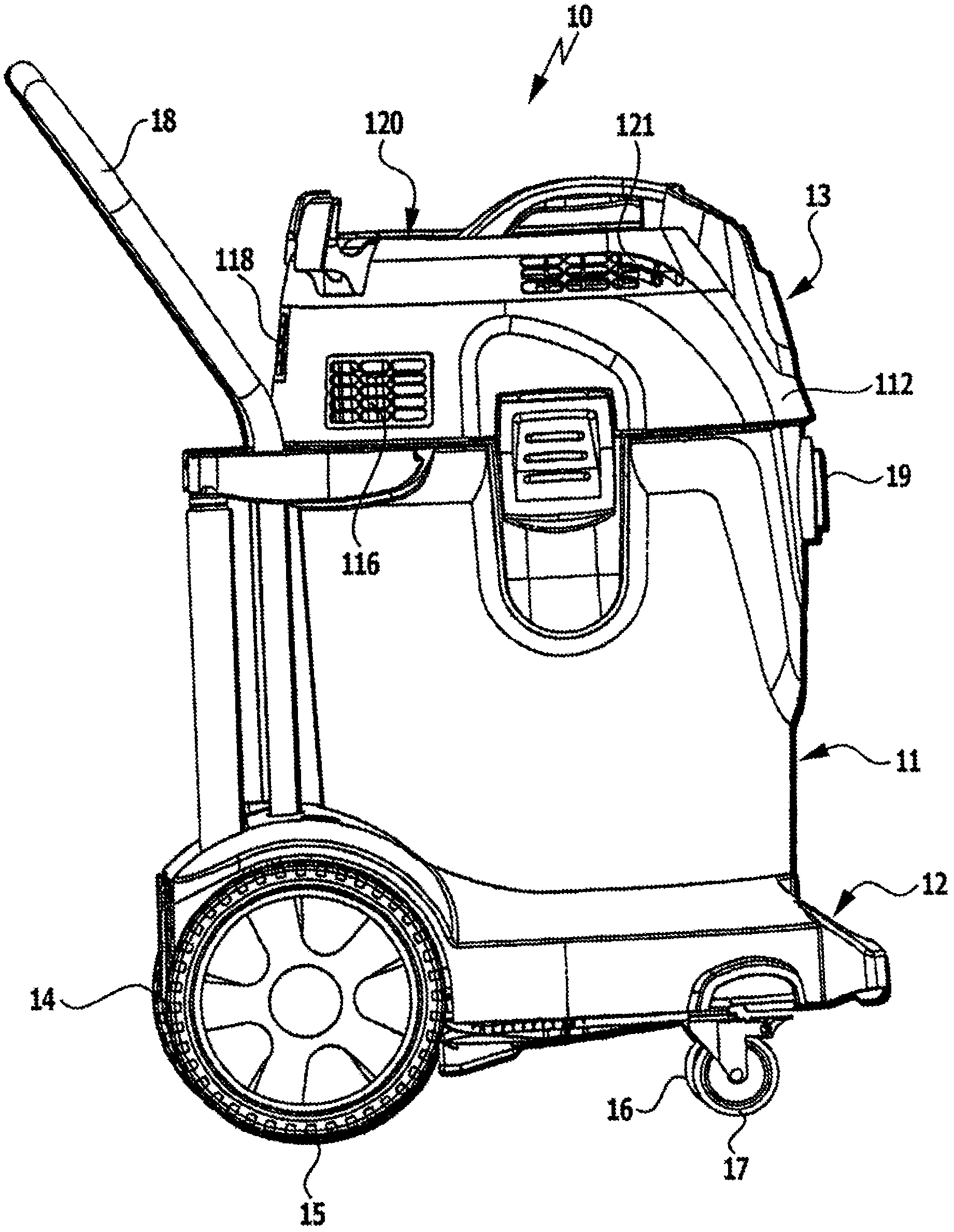

[0024] exist figure 1 A vacuum cleaner 10 according to the invention is shown schematically with a dirt collection container 11 which can be moved by means of a chassis 12 and on which a suction head 13 is fitted. The chassis 12 has two rear wheels 14 , 15 and two steerable front wheels 16 , 17 as well as a push bar 18 . The vacuum cleaner 10 can be moved along the ground surface by means of the chassis 12 . A suction hose can be connected to the suction connection 19 of the dirt collection container 11 in a conventional manner. The suction hose is not shown in the figures.

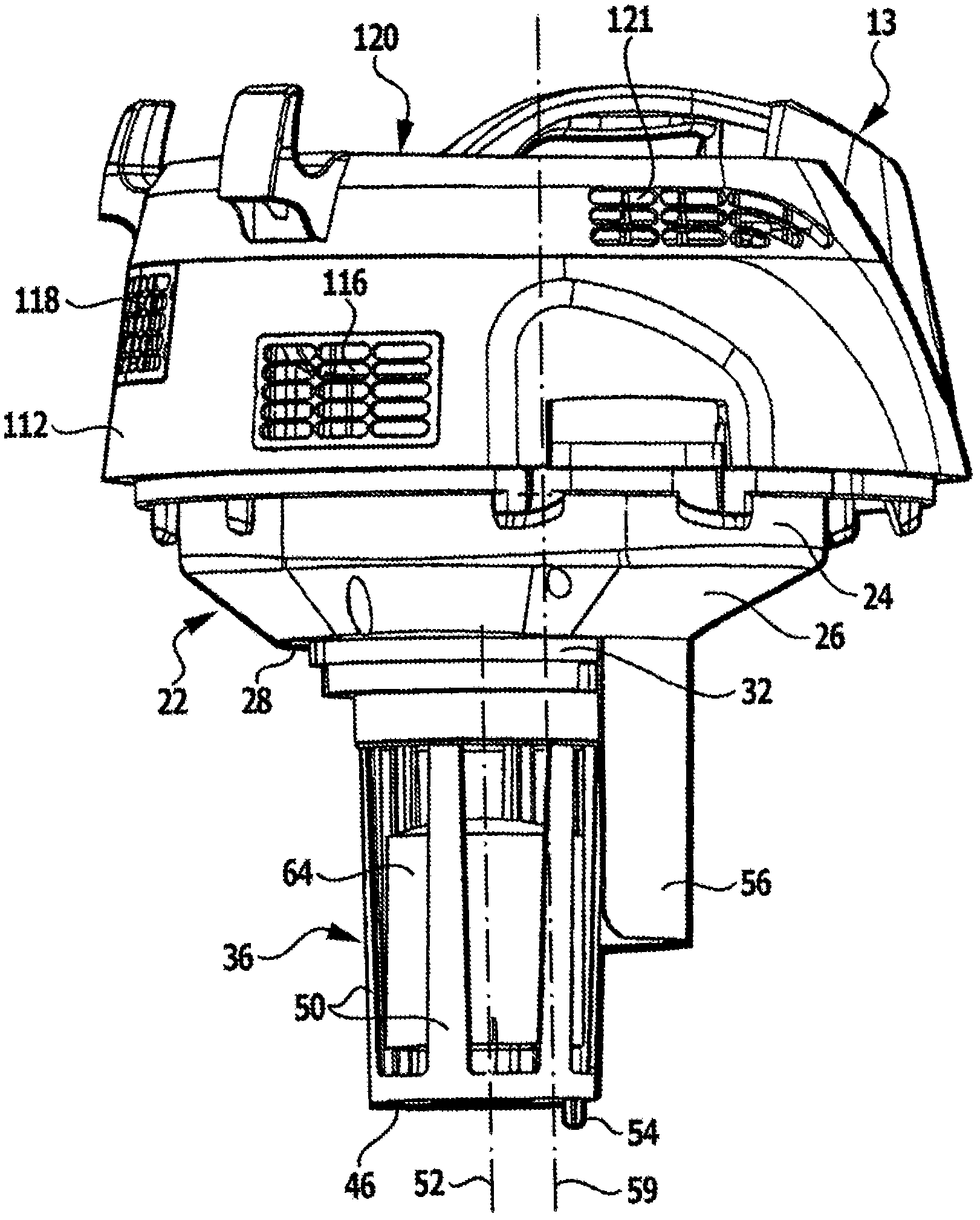

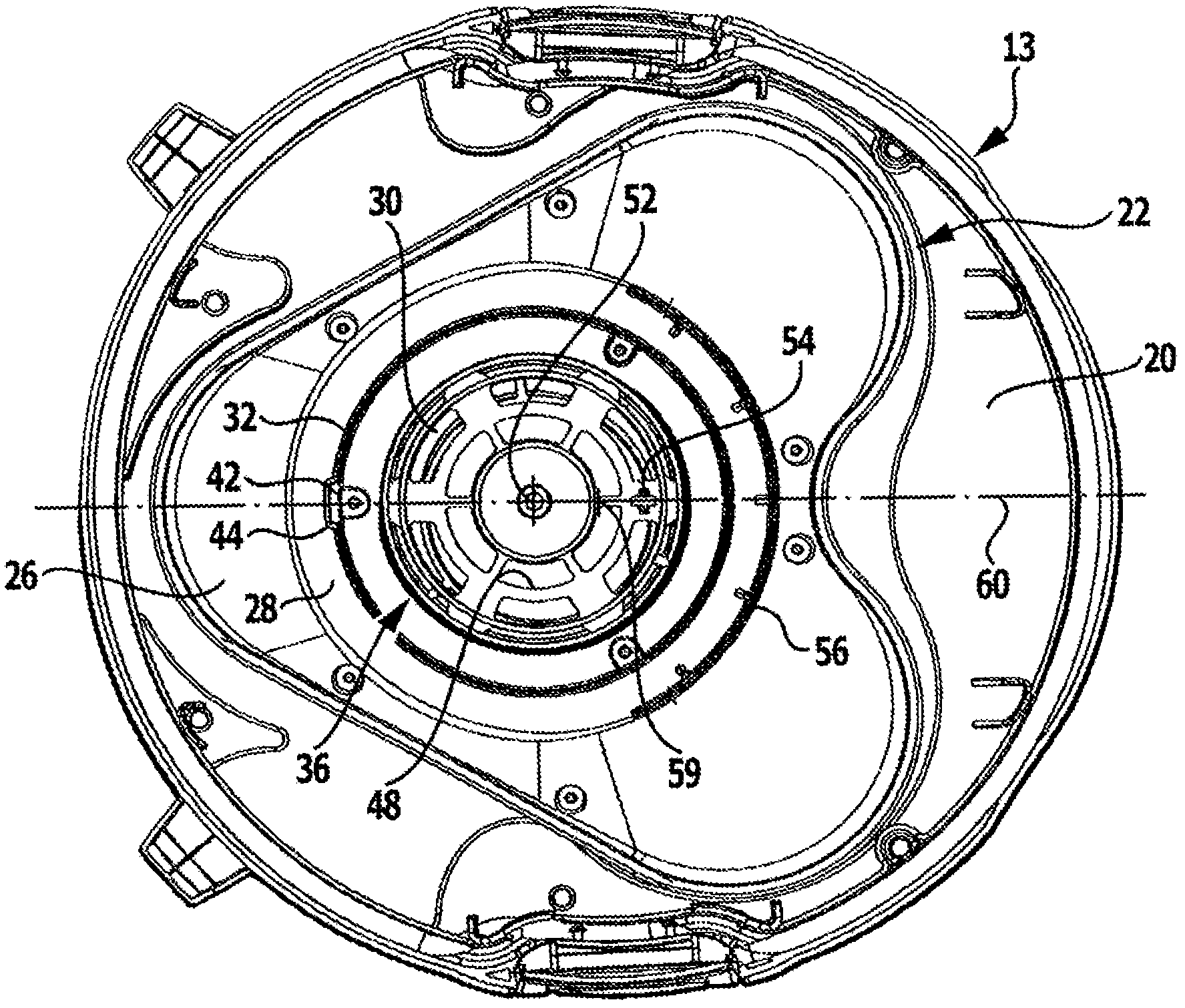

[0025] The suction head 13 can be removed from the dirt collection container 11 . The suction head 13 comprises a circular base plate 20 , on the underside of which a funnel-shaped suction inlet part 22 , which is heart-shaped in bottom view, is fastened. The suction inlet part 22 has an upper edge region 24 protruding flange-like from the underside of the base plate 20 , which defines a heart-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com