Method for comprehensively utilizing and processing gracilaria

A processing method and technology of Gracilaria, applied in the field of comprehensive utilization of Gracilaria, can solve problems such as polluting the environment and wasting resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

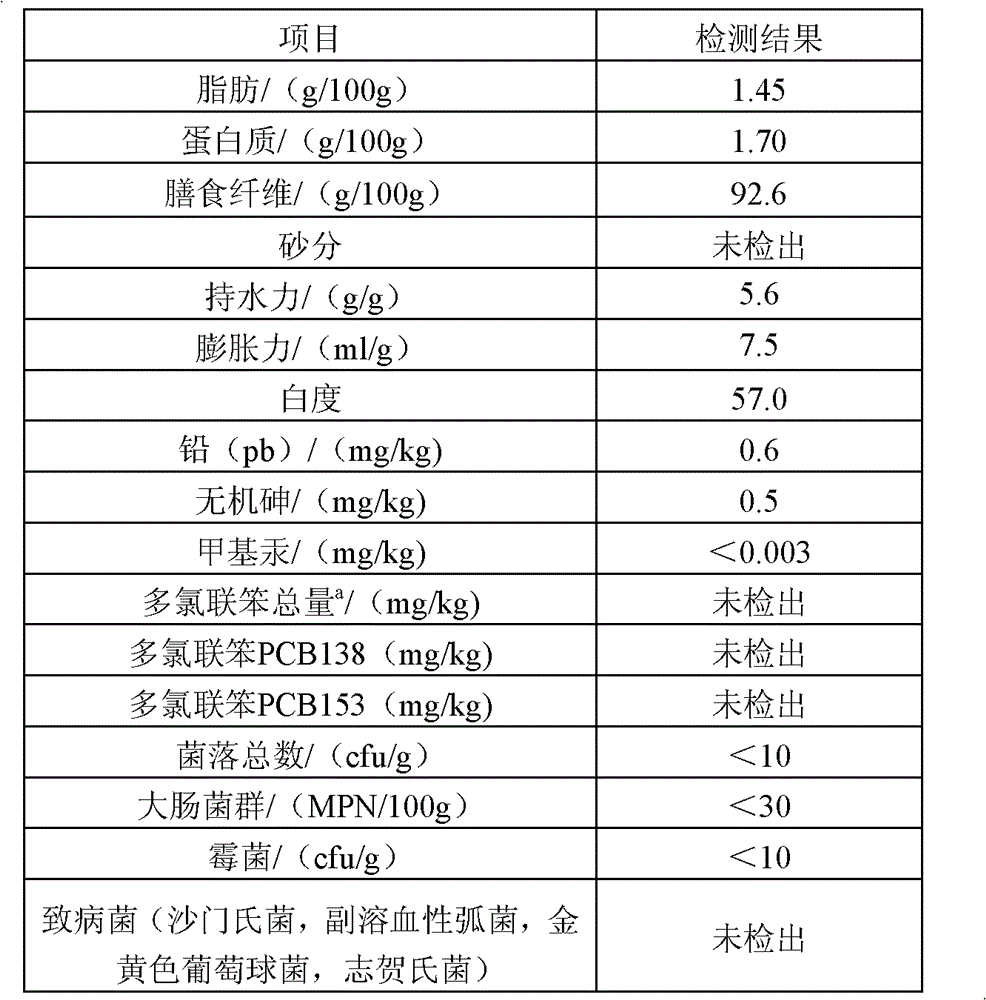

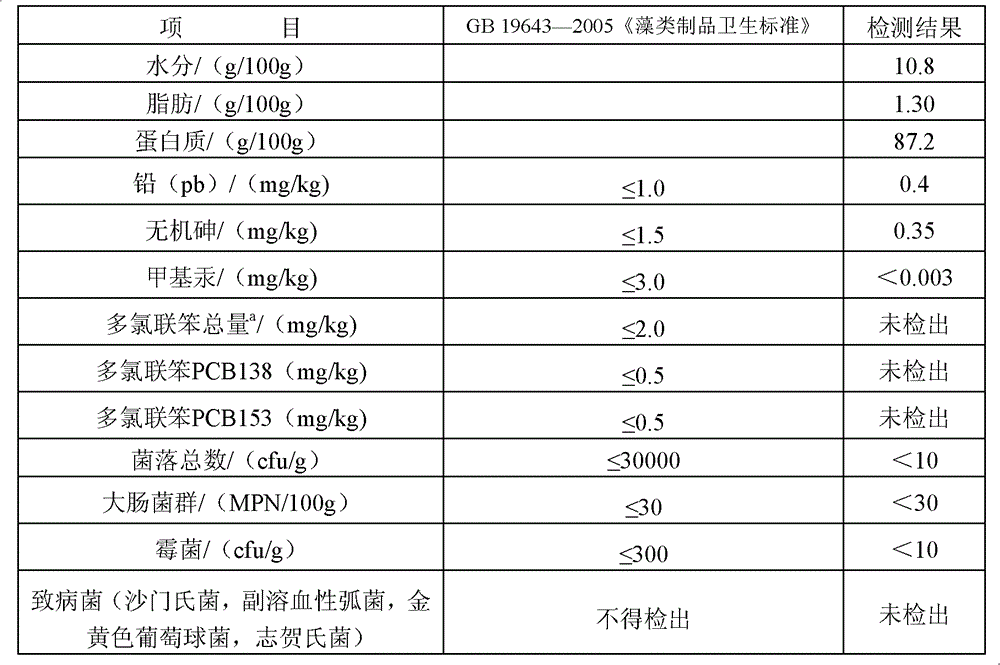

[0027] 1) Adjust the pH value of Gracilaria (ratio of material to liquid: 1:10) to 7, add papain with 3% mass of Gracilaria, adjust the temperature to 40° C. and hydrolyze for 8 hours, then filter, and heat the filtrate to 80° C. for 20 minutes. Phycoerythrin polypeptide is obtained after the enzyme is inactivated, concentrated and spray-dried; the physical and chemical indicators of the product are 10.8% moisture, 87.2% protein, and 1.3% fat.

[0028] 2) Add the residue obtained in step 1) to a 6% NaOH solution that is 3 times the wet weight of the residue, adjust the temperature to 90°C for 3 hours, then bleach with an allowed bleaching agent, and add water 8 times the total mass of the original Gracilaria after bleaching , heat up to 95°C and boil the glue for 4 hours, then use a plate and frame filter press to filter, the filtrate is solidified and chopped, then squeezed and dehydrated with an oil press, then dried at 50°C for 6 hours, and finally crushed with a pulverizer ...

Embodiment 2

[0032] 1) Adjust the pH value of Gracilaria (ratio of material to liquid: 1:12) to 9, add trypsin with 4% mass of Gracilaria, adjust the temperature to 38°C and hydrolyze for 7 hours, filter, and heat the filtrate to 80°C for 20 minutes to make Phycoerythrin polypeptide is obtained after the enzyme is inactivated, concentrated and spray-dried; the physical and chemical indicators of the product are 9.8% moisture, 88.0% protein, and 11% fat.

[0033] 2) Add the residue obtained in step 1) to a 7% NaOH solution that is 4 times the wet weight of the residue, adjust the temperature to 95°C for 2.5 hours, then bleach with an allowed bleaching agent, and add 10 times the total mass of the original Gracilaria after bleaching water, heated up to 90°C and boiled for 5 hours, then filtered with a plate and frame filter press, the filtrate was solidified and chopped, then dehydrated with an oil press, dried at 50°C for 6 hours, and finally crushed with a pulverizer to obtain powdered agar...

Embodiment 3

[0036] 1) Adjust the pH value of Gracilaria (material-to-liquid ratio 1:14) to 8, add 4.5% subtilisin of Gracilaria mass, adjust the temperature to 42°C and hydrolyze for 9 hours, filter, and heat the filtrate to 80°C for 20 minutes Inactivate the enzyme, then concentrate and spray-dry to obtain the phycoerythrin polypeptide; the physical and chemical indicators of the product are 9.0% moisture, 89.0% protein, and 11% fat, and the hygienic indicators comply with GB 19643-2005 "Hygienic Standards for Algae Products".

[0037] 2) Add the residue obtained in step 1) to an 8% NaOH solution that is 4.5 times the wet weight of the residue, adjust the temperature to 90°C for 3.0 hours, then bleach with an allowed bleaching agent, and add 12 times the total mass of the original Gracilaria after bleaching Water, warmed up to 95°C and boiled for 4.5 hours, then filtered with a plate and frame filter press, the filtrate was solidified and chopped, then squeezed and dehydrated with an oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com