Method for comprehensively utilizing and processing gracilaria

A processing method and technology of Gracilaria, applied in the field of comprehensive utilization of Gracilaria, can solve the problems of polluting the environment, wasting resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

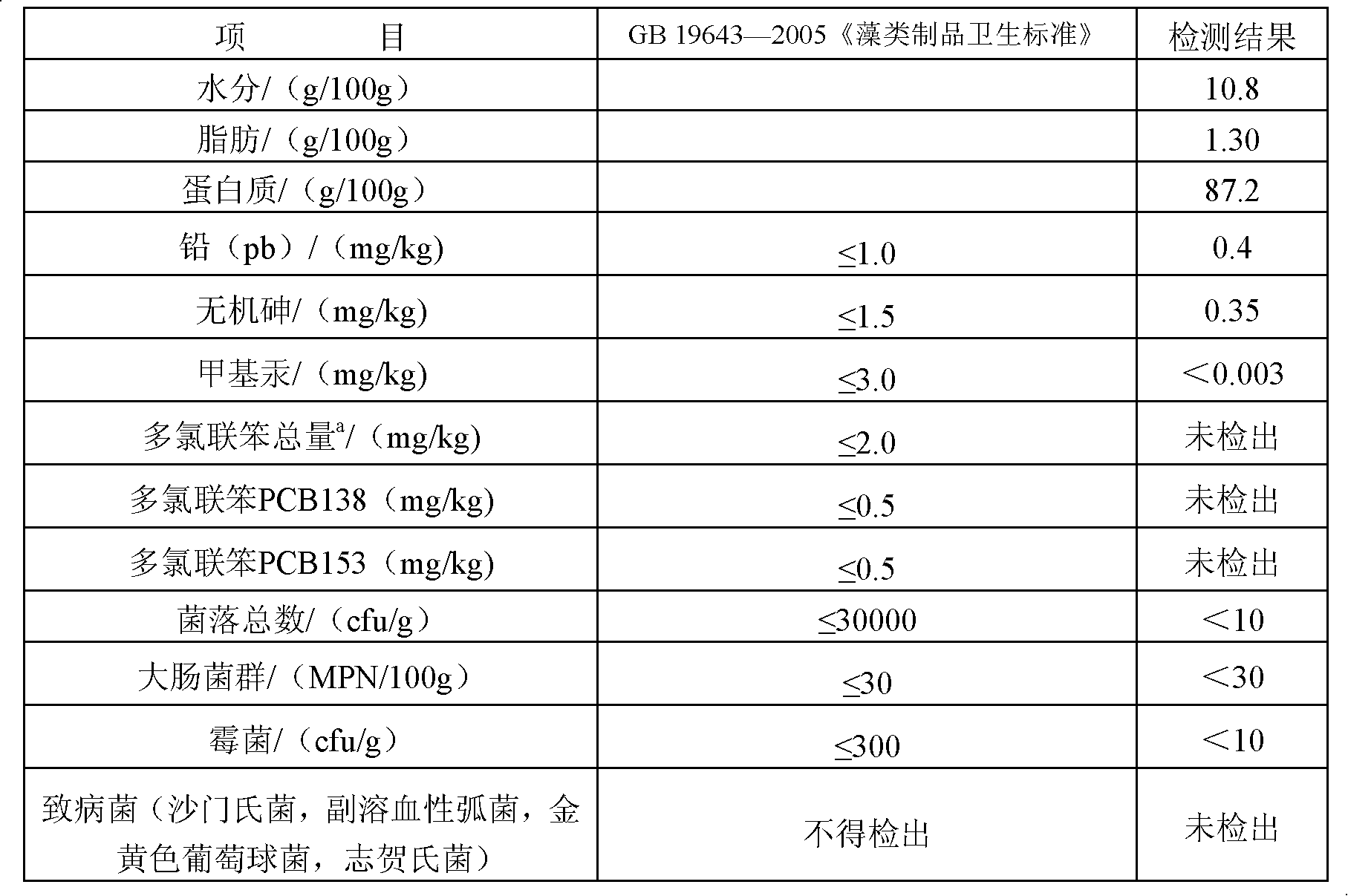

[0027] 1) Adjust the pH value of Gracilaria (ratio of material to liquid: 1:10) to 7, add papain with 3% mass of Gracilaria, adjust the temperature to 40° C. and hydrolyze for 8 hours, then filter, and heat the filtrate to 80° C. for 20 minutes. Phycoerythrin polypeptide is obtained after the enzyme is inactivated, concentrated and spray-dried; the physical and chemical indicators of the product are 10.8% moisture, 87.2% protein, and 1.3% fat.

[0028] 2) Add the residue obtained in step 1) to a 6% NaOH solution that is 3 times the wet weight of the residue, adjust the temperature to 90°C for 3 hours, then bleach with an allowed bleaching agent, and add water 8 times the total mass of the original Gracilaria after bleaching , heat up to 95°C and boil the glue for 4 hours, then use a plate and frame filter press to filter, the filtrate is solidified and chopped, then squeezed and dehydrated with an oil press, then dried at 50°C for 6 hours, and finally crushed with a pulverizer ...

Embodiment 2

[0032] 1) Adjust the pH value of Gracilaria (ratio of material to liquid: 1:12) to 9, add trypsin with 4% mass of Gracilaria, adjust the temperature to 38°C and hydrolyze for 7 hours, filter, and heat the filtrate to 80°C for 20 minutes to make Phycoerythrin polypeptide is obtained after the enzyme is inactivated, concentrated and spray-dried; the physical and chemical indicators of the product are 9.8% moisture, 88.0% protein, and 11% fat.

[0033] 2) Add the residue obtained in step 1) to a 7% NaOH solution that is 4 times the wet weight of the residue, adjust the temperature to 95°C for 2.5 hours, then bleach with an allowed bleaching agent, and add 10 times the total mass of the original Gracilaria after bleaching water, heated up to 90°C and boiled for 5 hours, then filtered with a plate and frame filter press, the filtrate was solidified and chopped, then dehydrated with an oil press, dried at 50°C for 6 hours, and finally crushed with a pulverizer to obtain powdered agar...

Embodiment 3

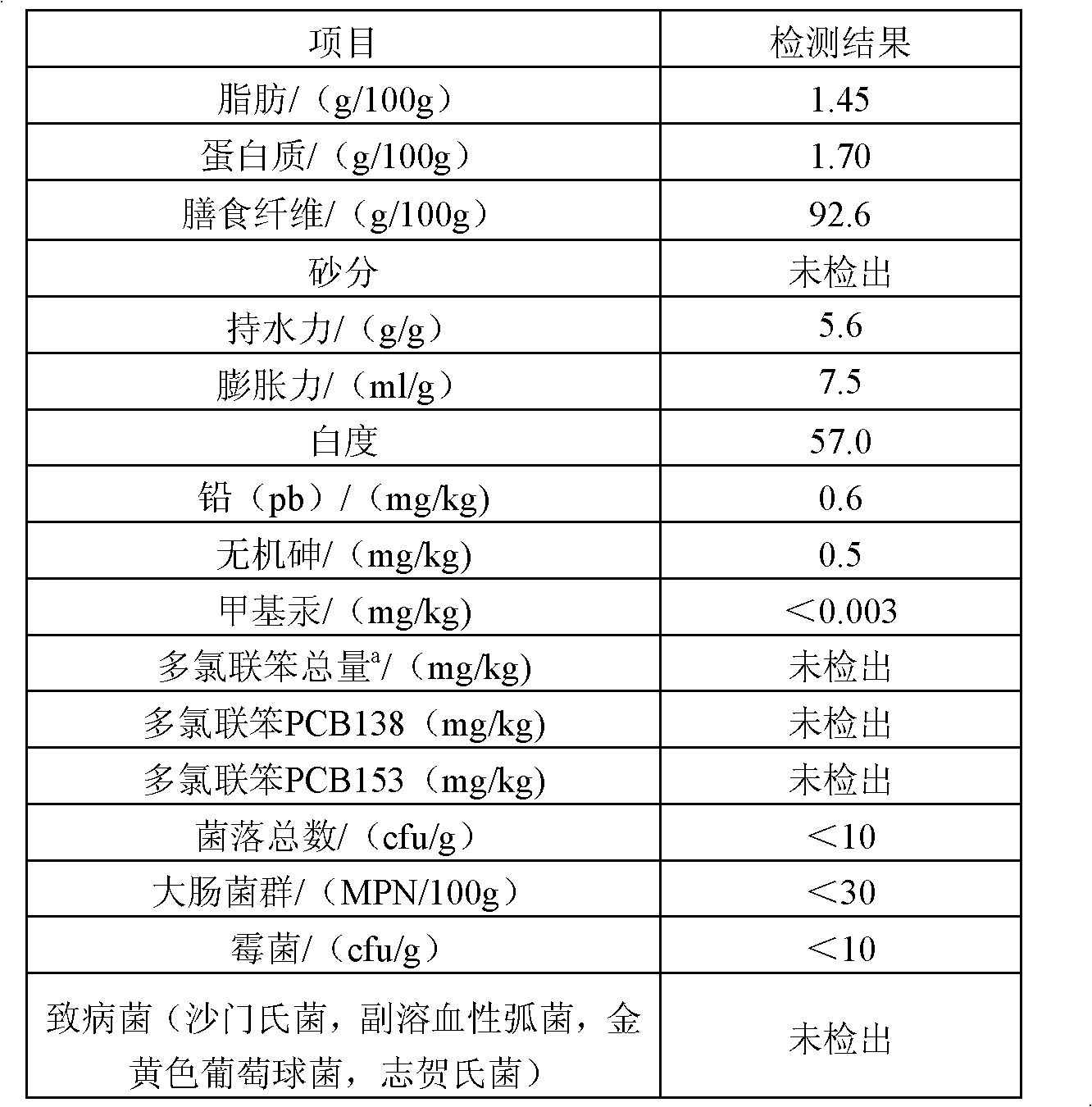

[0036] 1) Adjust the pH value of Gracilaria (material-to-liquid ratio 1:14) to 8, add 4.5% subtilisin of Gracilaria mass, adjust the temperature to 42°C and hydrolyze for 9 hours, filter, and heat the filtrate to 80°C for 20 minutes Inactivate the enzyme, then concentrate and spray-dry to obtain the phycoerythrin polypeptide; the physical and chemical indicators of the product are 9.0% moisture, 89.0% protein, and 11% fat, and the hygienic indicators comply with GB 19643-2005 "Hygienic Standards for Algae Products".

[0037] 2) Add the residue obtained in step 1) to an 8% NaOH solution that is 4.5 times the wet weight of the residue, adjust the temperature to 90°C for 3.0 hours, then bleach with an allowed bleaching agent, and add 12 times the total mass of the original Gracilaria after bleaching Water, warmed up to 95°C and boiled for 4.5 hours, then filtered with a plate and frame filter press, the filtrate was solidified and chopped, then squeezed and dehydrated with an oil ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Expansion force | aaaaa | aaaaa |

| Expansion force | aaaaa | aaaaa |

| Expansion force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com