Garlic peeling machine

The technology of a garlic peeling machine and a motor shaft is applied in the peeling of vegetables or fruits, food science, application and other directions, and can solve the problems of low production efficiency and difficulty in meeting the production requirements of large food processing enterprises.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

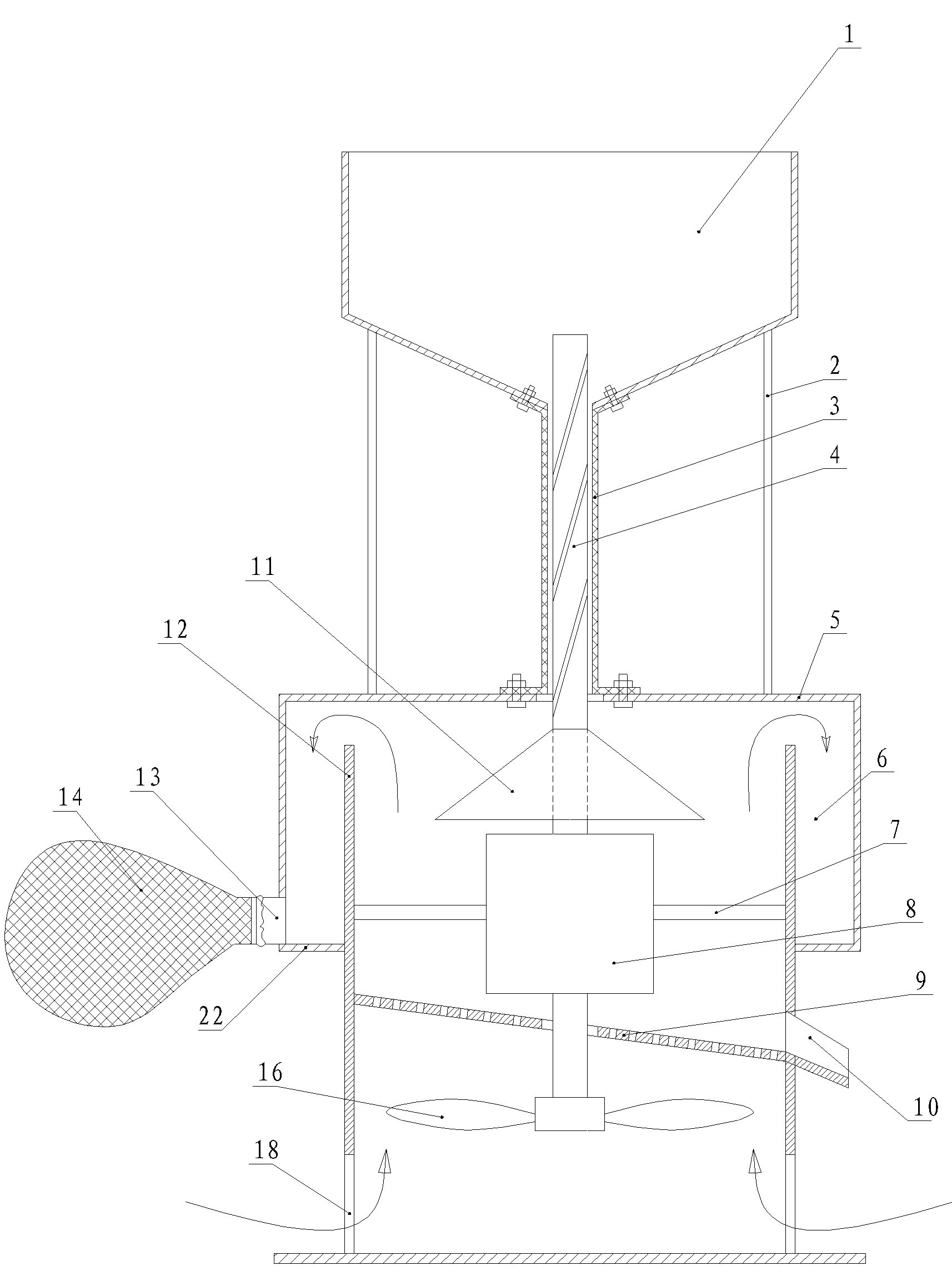

[0027] Embodiment one: see figure 1 In the figure, a garlic peeling machine includes a hopper, a peeling device, and a separation device. The peeling device includes an internal auger and an elastic friction sleeve set outside the auger. The upper and lower ends of the elastic friction sleeve are respectively connected to the The lower part of the hopper and the upper part of the separation device, the separation device includes an inner cylinder and an outer cylinder, an upper cover and a lower ring plate, the lower ring plate is fixedly connected to the outer surface of the inner cylinder, and the outer cylinder is installed on the lower On the ring plate, the upper cover is installed on the upper part of the outer cylinder, the lower end of the elastic friction sleeve is installed in the middle of the upper cover, and there is a certain distance between the upper edge of the inner cylinder and the upper cover; the separation device also includes a The motor inside the cylin...

Embodiment 2

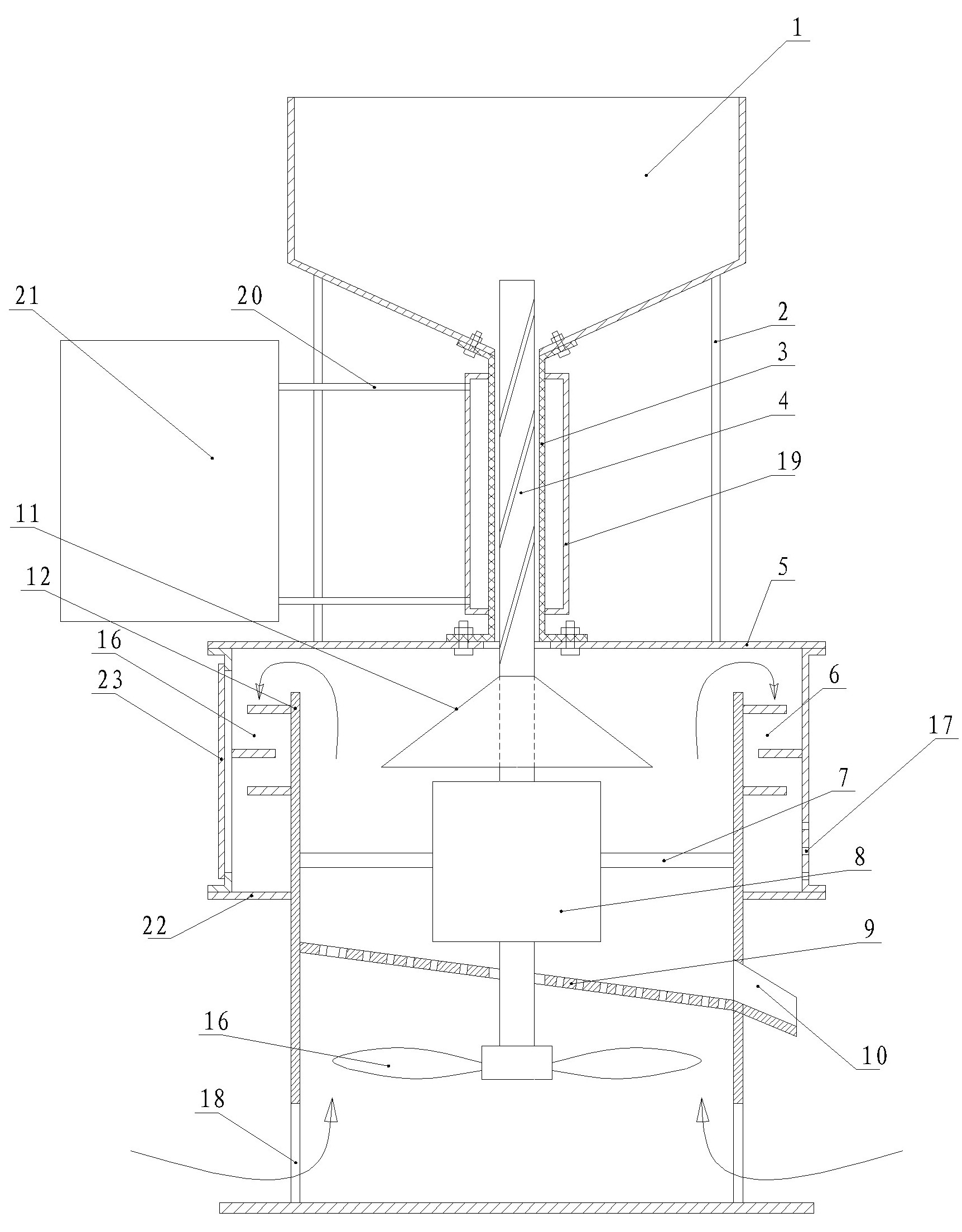

[0030] Embodiment two: see figure 2 In the figure, a garlic peeling machine includes a hopper, a peeling device, and a separation device. The peeling device includes an internal auger and an elastic friction sleeve set outside the auger. The upper and lower ends of the elastic friction sleeve are respectively connected to the The lower part of the hopper and the upper part of the separation device, the separation device includes an inner cylinder and an outer cylinder, an upper cover and a lower ring plate, the lower ring plate is fixedly connected to the outer surface of the inner cylinder, and the outer cylinder is installed on the lower On the ring plate, the upper cover is installed on the upper part of the outer cylinder, the lower end of the elastic friction sleeve is installed in the middle of the upper cover, and there is a certain distance between the upper edge of the inner cylinder and the upper cover; the separation device also includes a The motor inside the cyli...

Embodiment 3

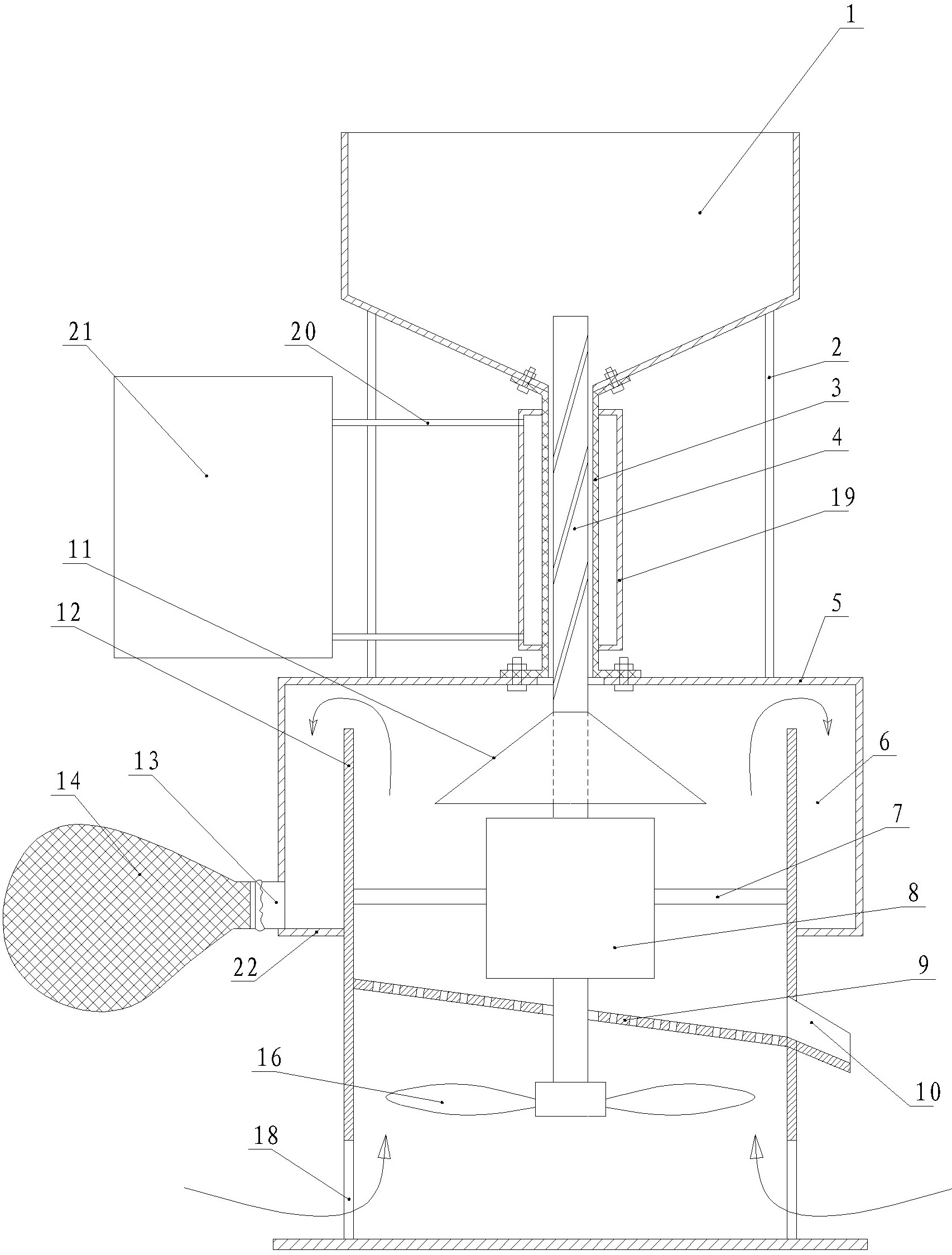

[0033] Embodiment three: see image 3 In the figure, a garlic peeling machine includes a hopper, a peeling device, and a separation device. The peeling device includes an internal auger and an elastic friction sleeve set outside the auger. The upper and lower ends of the elastic friction sleeve are respectively connected to the The lower part of the hopper and the upper part of the separation device, the separation device includes an inner cylinder and an outer cylinder, an upper cover and a lower ring plate, the lower ring plate is fixedly connected to the outer surface of the inner cylinder, and the outer cylinder is installed on the lower On the ring plate, the upper cover is installed on the upper part of the outer cylinder, the lower end of the elastic friction sleeve is installed in the middle of the upper cover, and there is a certain distance between the upper edge of the inner cylinder and the upper cover; the separation device also includes a The motor inside the cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com