Linear-driven high-speed planar parallel mechanical arm

A linear drive and manipulator technology, applied in the field of manipulators, can solve problems such as low bearing capacity, achieve high positioning accuracy and repeat positioning accuracy, high positioning accuracy and repeat positioning accuracy, and improve overall stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

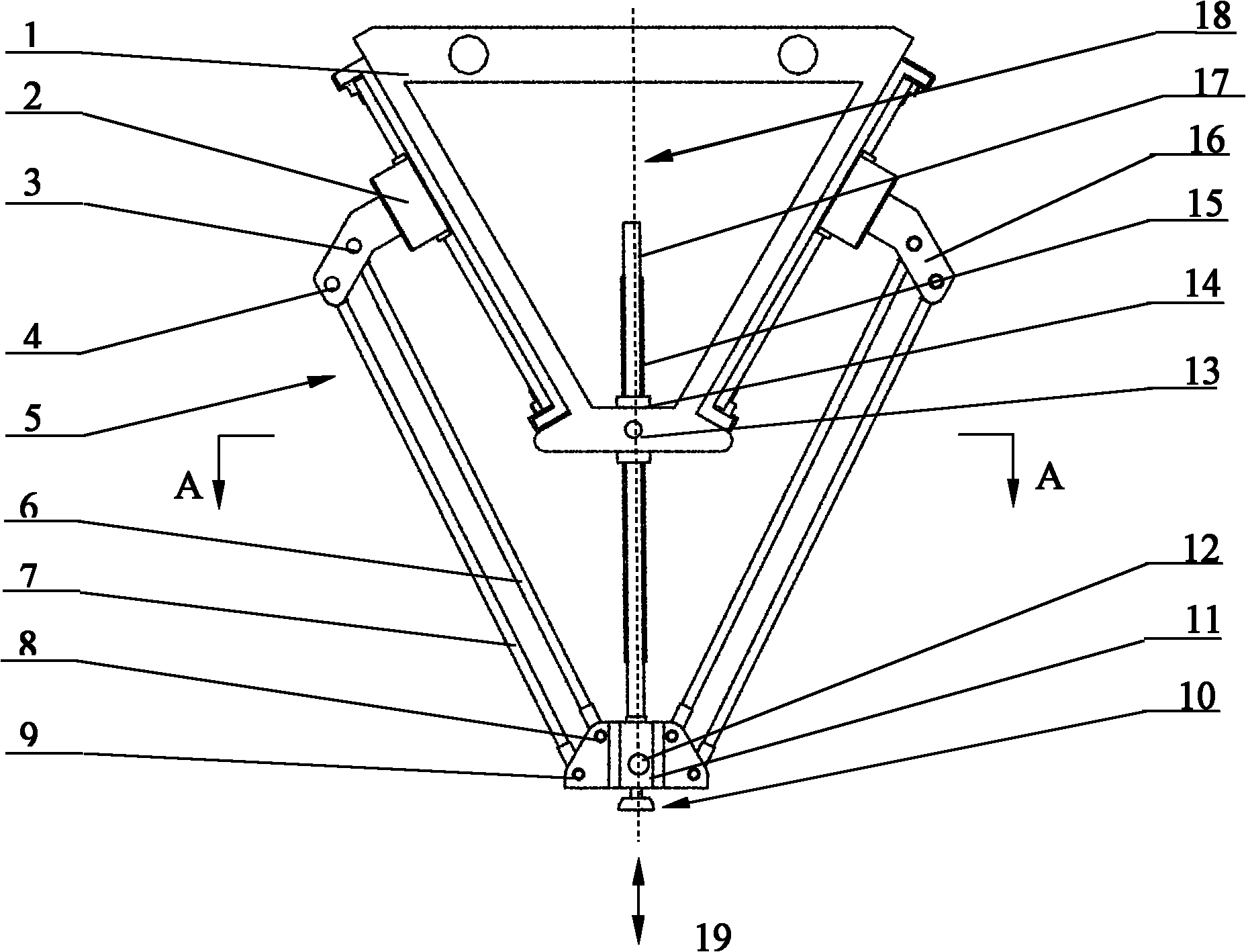

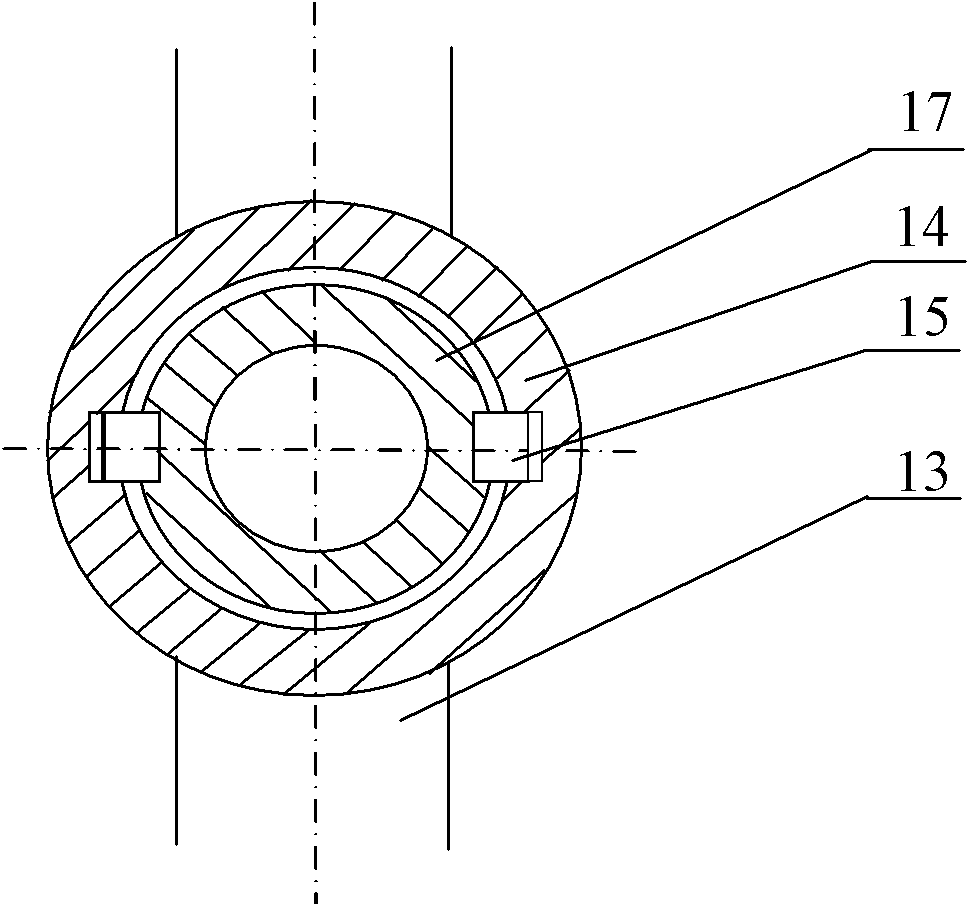

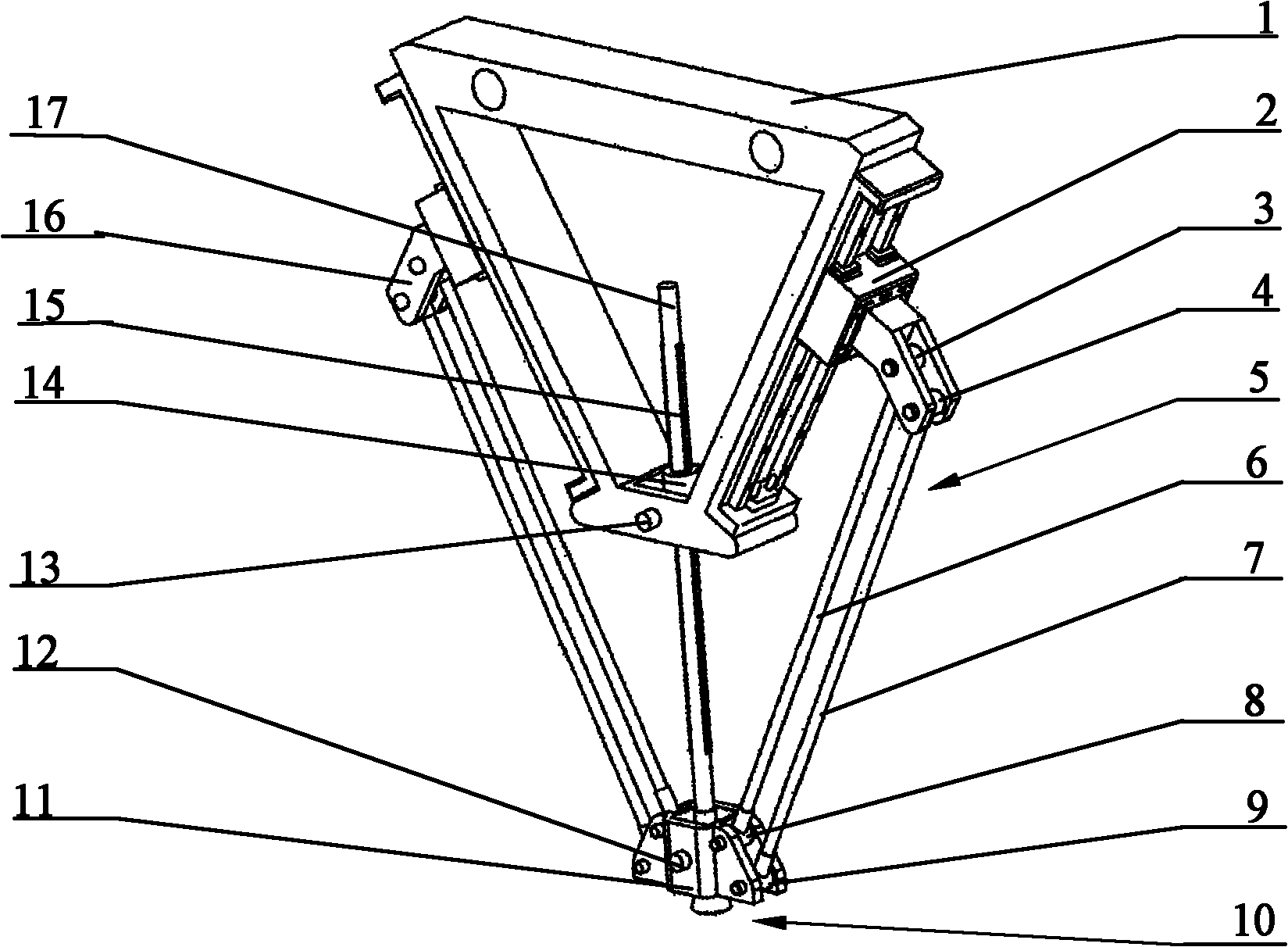

[0025] see Figure 1 to Figure 5 , a linear-driven high-speed planar parallel manipulator, including a machine base 1, two linear motors 2 and two kinematic chains 5 connected between the linear motors 2 and the moving platform 11, guide rods 17, sleeves 14, and the moving platform 11. figure 1 Middle dotted line 18 represents a plane perpendicular to the mechanism by the guide bar, Figure 1 to Figure 5 The mechanism in is symmetric about this plane. The mechanism uses a linear motor 2 as a driving component, and the linear motor 2 moves linearly along the fixed guide rail. The sleeve 14 is connected with the base 1 through two coaxial pins 13 on its outer wall; the guide rod 17 is installed on the base 1 through the sleeve 14, and its lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com