Bridge crane trolley for mine

A technology of bridge crane and trolley, which is applied in the direction of load trolley, traveling mechanism, load hanging element, etc., can solve the problems of equipment hoisting, maintenance and replacement difficulties, etc., and achieve the effect of solving hoisting difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

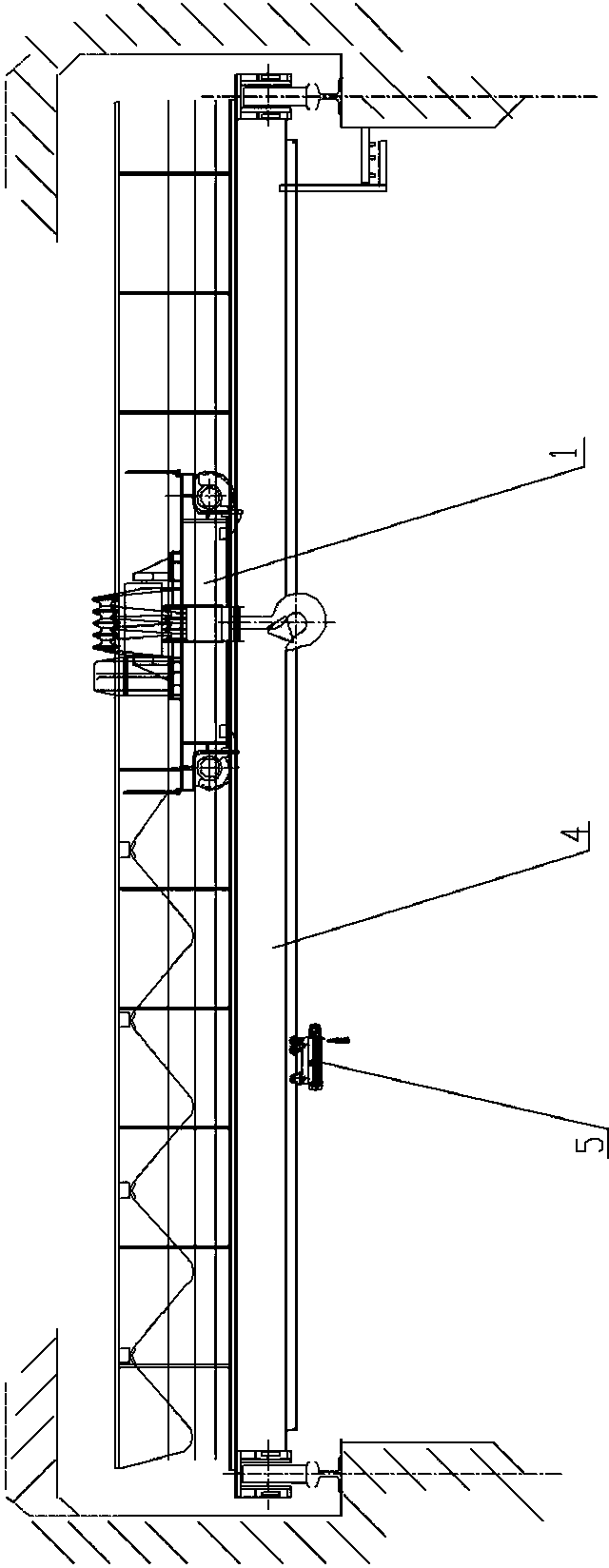

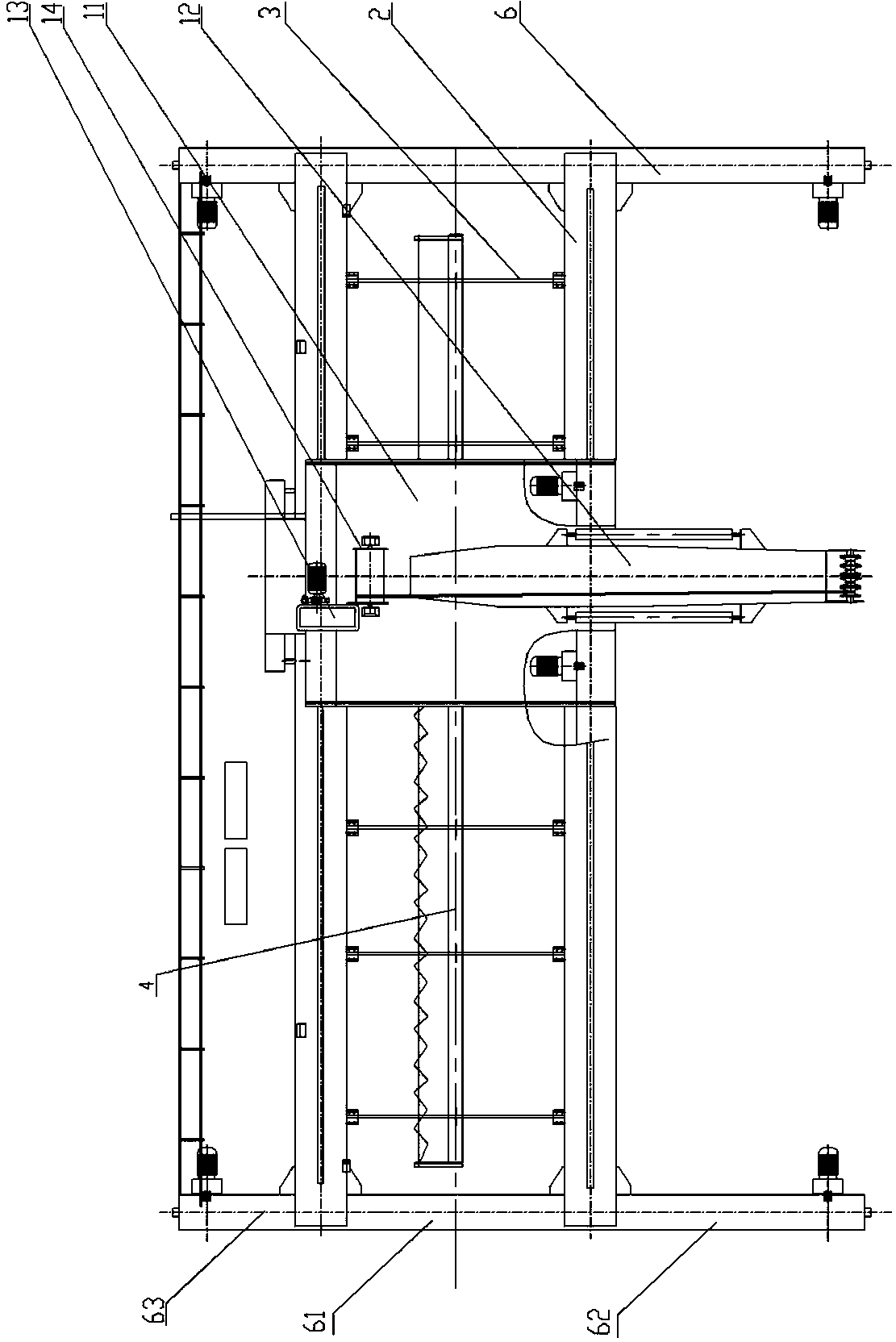

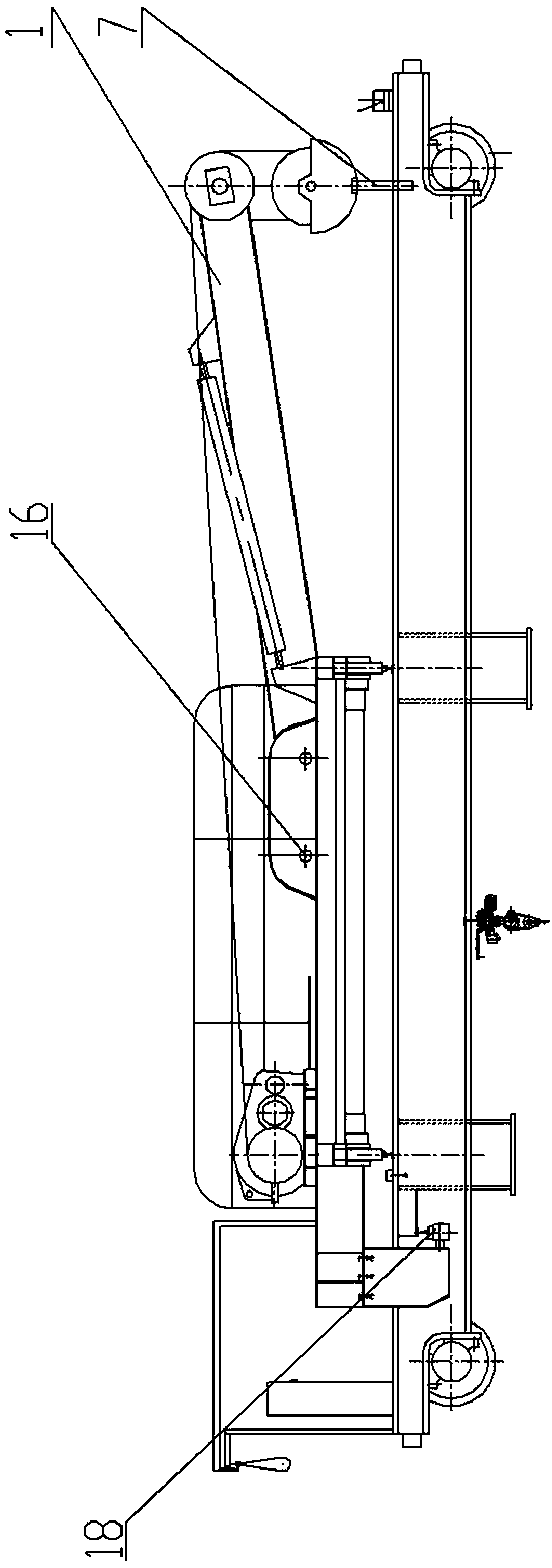

[0019] Such as Figure 1 to Figure 5 As shown, a bridge crane for mines includes two main beams 2 horizontally arranged, and two end beams 6 are fixedly connected to the ends of the two main beams 2. The main beam 2 and the end beam 6 constitute a crane bridge frame. The end beam 6 is provided with a trolley traveling mechanism, which includes wheels arranged at both ends of the end beam and a traveling motor for driving the wheels to rotate, and a guide rail extending in the extension direction of the main beam is fixed on the main beam 2 A crane trolley 1 is provided on the guide rail. The crane trolley 1 includes a trolley chassis 11 slidably mounted on the guide rail. A reel 14 is provided on the trolley chassis 11, and the reel 14 is driven by a motor 13 to roll on the trolley chassis 11. One side of the tube 14 is fixedly provided with a cantilever beam 12 outside the chassis of the trolley extending upward, and the cantilever beam 12 is arranged obliquely to the plane of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com