Grain condition prediction system, grain condition control system and grain bulk safety state judging method

A technology for predicting system and safety status, applied to measuring devices, measuring heat, instruments, etc., can solve the problems of increasing false alarms, grain storage quality control, and high blindness in prevention and control, and achieve accurate safety control information, fast speed, and forecasting accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The content of the invention of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

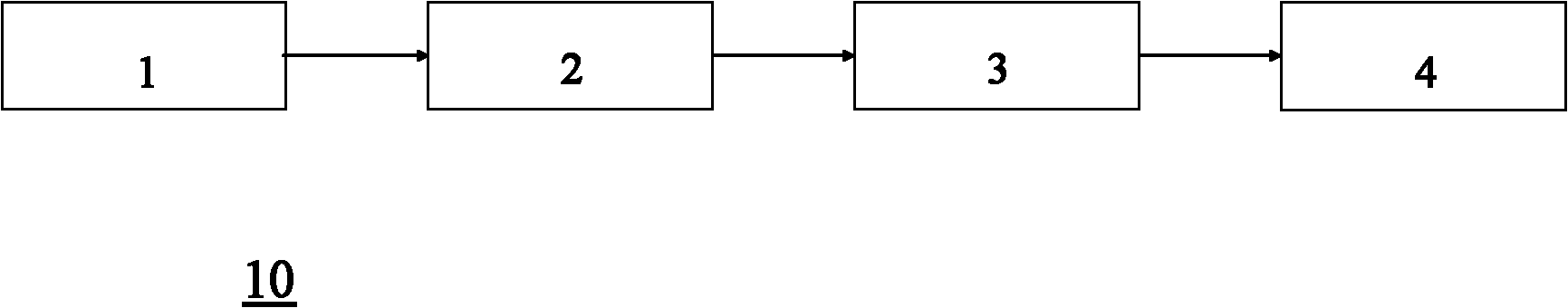

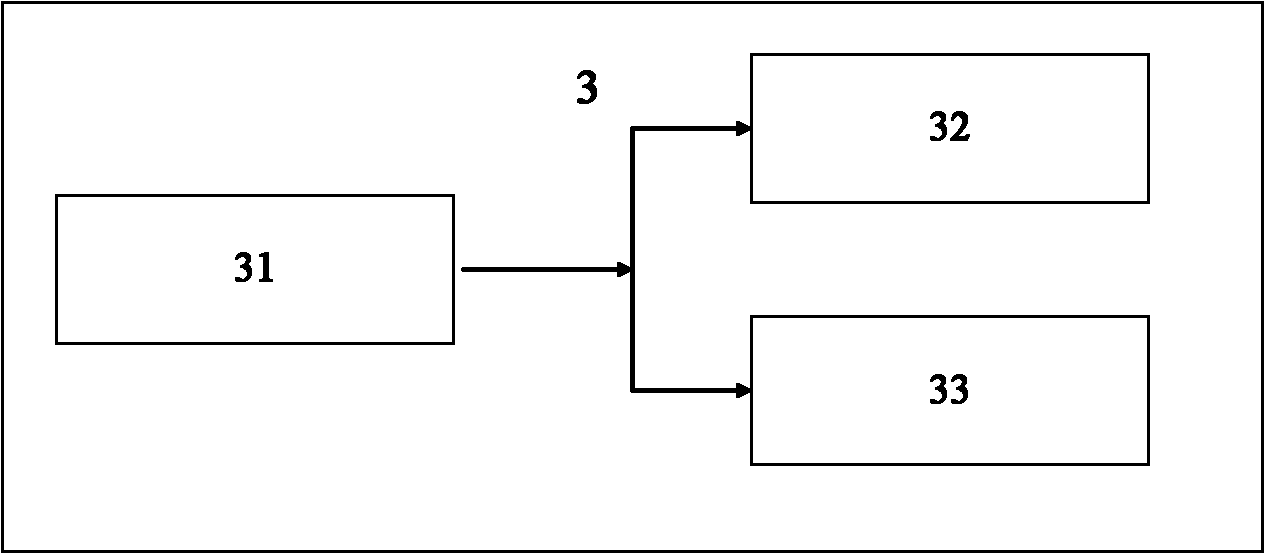

[0034] Such as figure 1 As shown, a grain forecasting system 10 includes a plurality of temperature sensors 1, a storage unit 2, an analysis unit 3, and an alarm unit 4, and temperature thresholds T are set for each detection position in the grain pile. max and temperature change rate difference threshold ΔK max .

[0035] The temperature sensor 1 is used to detect the temperature T of each position in the grain pile, and transmits it to the storage unit 2 through a data transmission cable. Temperature sensor 1 can adopt wired or wireless temperature sensor, such as DS18B20 type temperature sensor, pt thermistor type temperature sensor etc., set a plurality of temperature detection points on the upper layer, middle layer and lower layer of the grain pile as required, temperature acquisition frequency such as at least 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com