Method for winding battery cell of lithium ion

A lithium-ion battery technology, applied in the winding field of lithium-ion batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

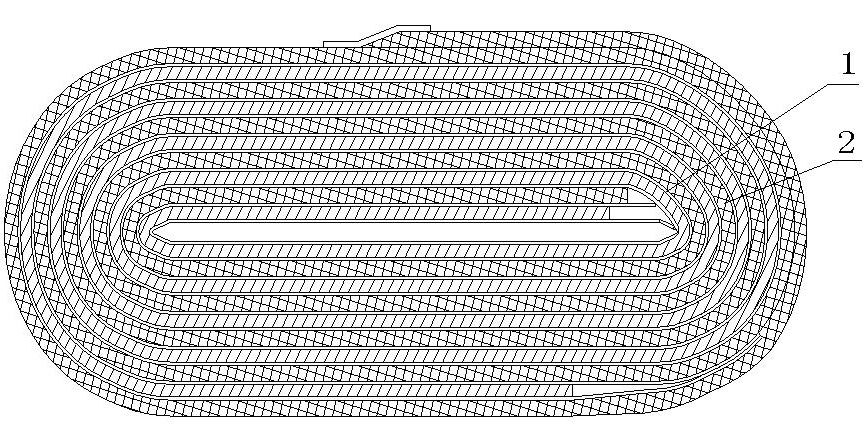

Image

Examples

Embodiment 1

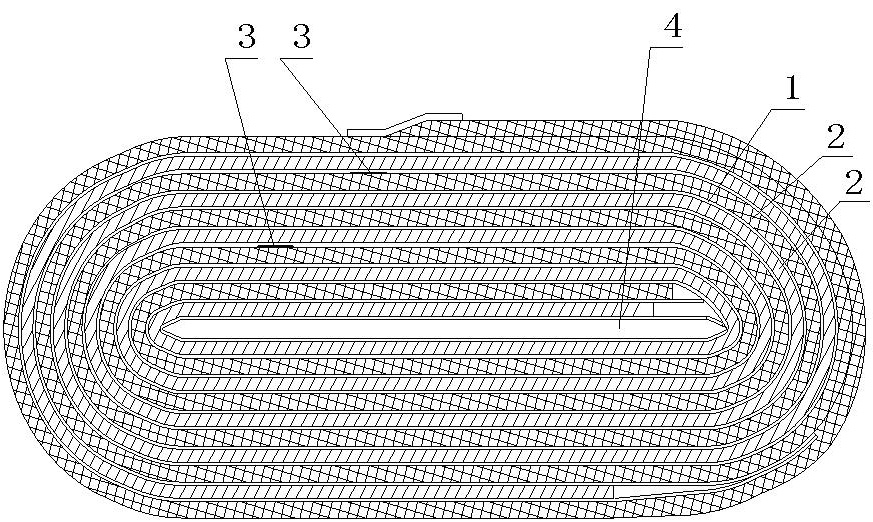

[0020] Such as figure 2 As shown, the winding method of the lithium ion battery core of the present embodiment, its specific operation process includes:

[0021] Manually fold the cut pole piece 2 and diaphragm 1 in sequence, and wind the starting end on the main winding needle 4, and the main winding needle driving mechanism drives the main winding needle 4 to rotate, driving the pole piece that has been positioned at the starting end. After the sheet 2 and the diaphragm 1 are wound to a predetermined thickness, the predetermined thickness is preferably 4 to 5 mm; the driving mechanism is stopped, and an auxiliary winding needle 3 is manually positioned in parallel with the main winding needle 4 on the pole piece of the predetermined thickness shown On the surface, the driving mechanism works to drive the main winding needle 4 to continue to rotate. After winding one circle, release the auxiliary winding needle while continuing to wind, and continue to wind the predetermined...

Embodiment 2

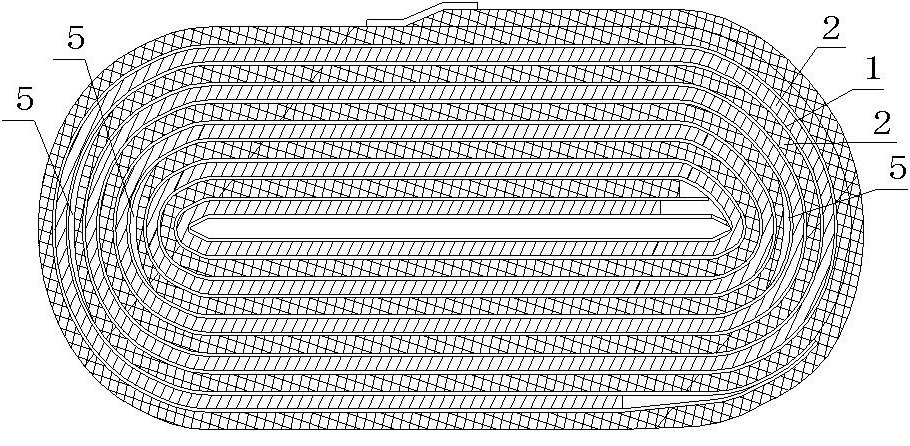

[0024] The lithium-ion battery winding method in Example 1 adopts a semi-manual method, and some operations need to be manually completed by human operators, and the winding efficiency is low. The cell winding method of the present invention is also suitable for use on automatic winding equipment, and its specific implementation steps are as follows:

[0025] Install the coils of the pole piece and the diaphragm on the automatic unwinding mechanism respectively, and wind the starting ends of the diaphragm and the pole piece on the main winding needle of the automatic winding equipment, and the diaphragm and the pole piece are automatically unwound by the automatic unwinding mechanism. Unwind, automatically enter the winding section, the main winding needle is located in the winding section, the driving mechanism drives the main winding needle to rotate, drives the pole piece and diaphragm positioned at the starting end to wind to a predetermined thickness, the driving mechanism...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com