Filter

A technology for filters and filter areas, applied in the direction of fixed filter element filters, filtration separation, chemical instruments and methods, etc., can solve the problems of affecting the filtering effect, clogging the filter element, and poor sewage discharge effect, so as to achieve good sewage discharge effect and improve The effect of the filter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

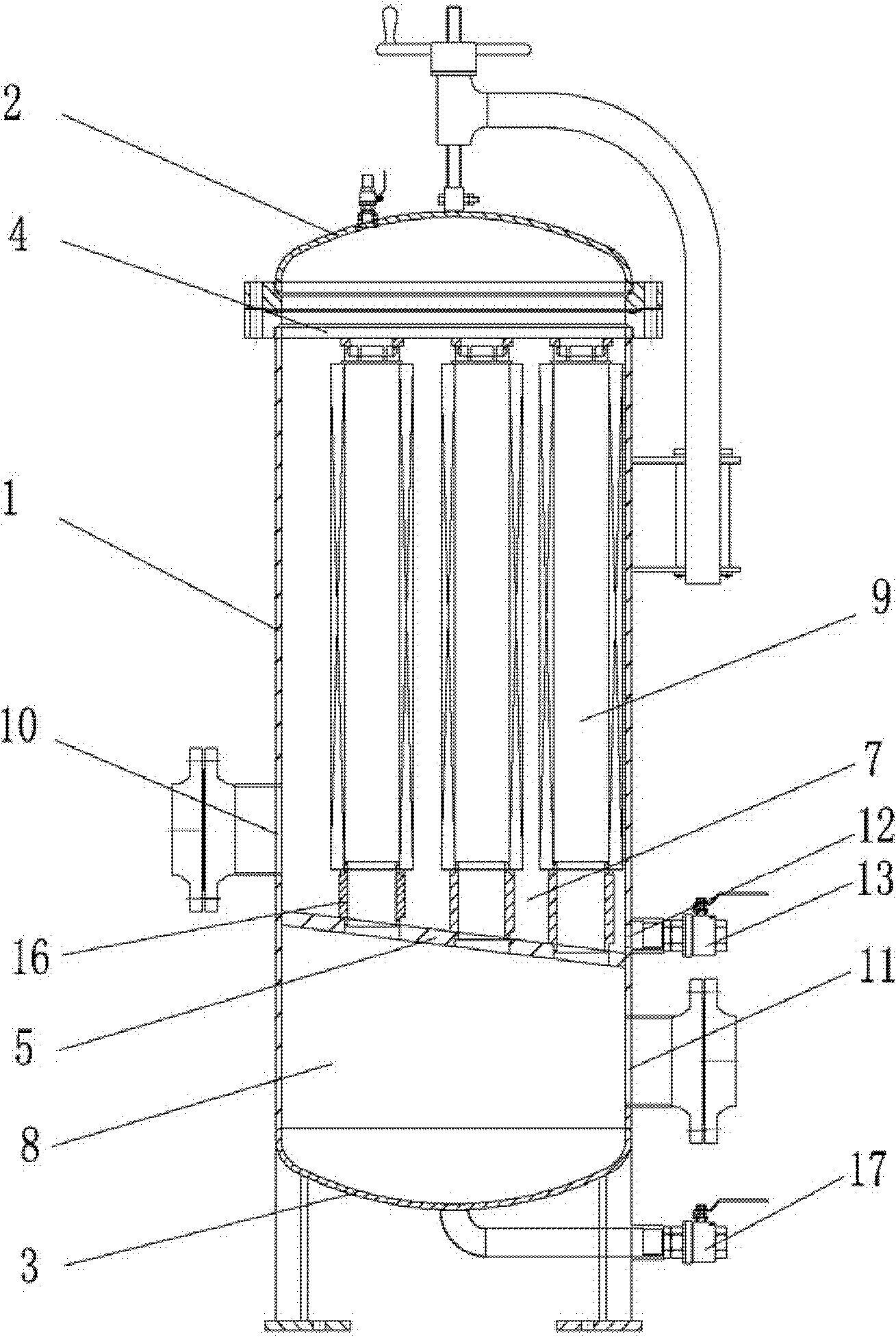

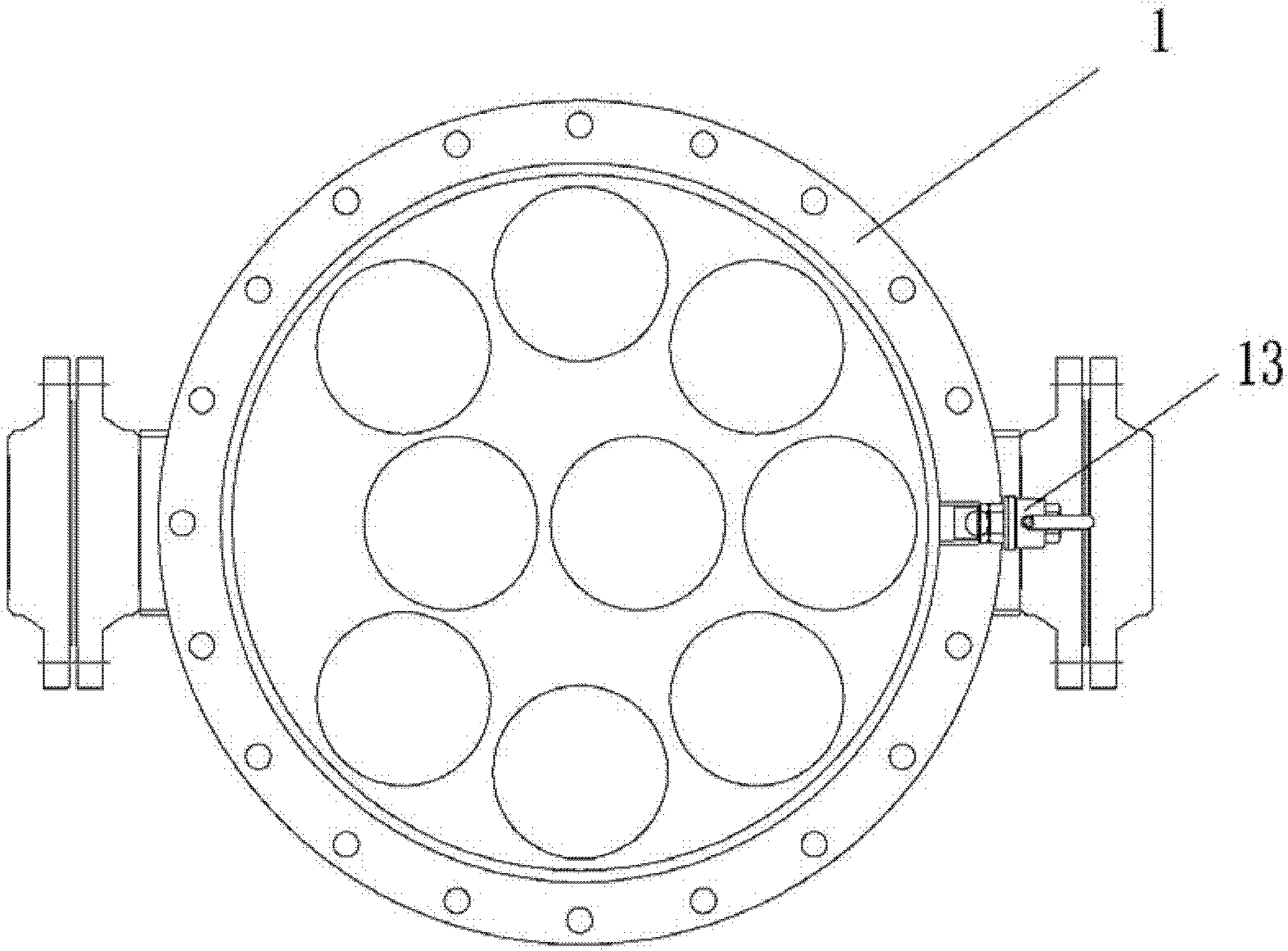

[0020] Such as figure 1 , figure 2 As shown, the filter of the present invention includes: a cylindrical body 1, an upper end cap 2, a lower end cap 3, a pressing plate 4, a filter element 9, a filter element seat 16 and a tube sheet 5, a cylindrical body 1, an upper end cap 2 and a lower end cap 2. The head 3 forms a tank-shaped body with a cavity in the center, the pressure plate 4 is connected to the top inner wall of the cylinder body 1, the tube plate 5 is arranged obliquely and fixedly connected with the inner wall of the cylinder body 1, and the tube plate 5 seals the cavity of the tank-shaped body Separated into a filter area 7 and a clean liquid area 8, the upper end of the filter element 9 is connected to the pressure plate 4, the lower end of the filter element 9 is connected to the tube plate 5 through the filter element seat 16, and the side wall of the cylinder body 1 is provided with a liquid inlet 10, The liquid outlet 11 and the sewage outlet 12, the liquid ...

Embodiment 2

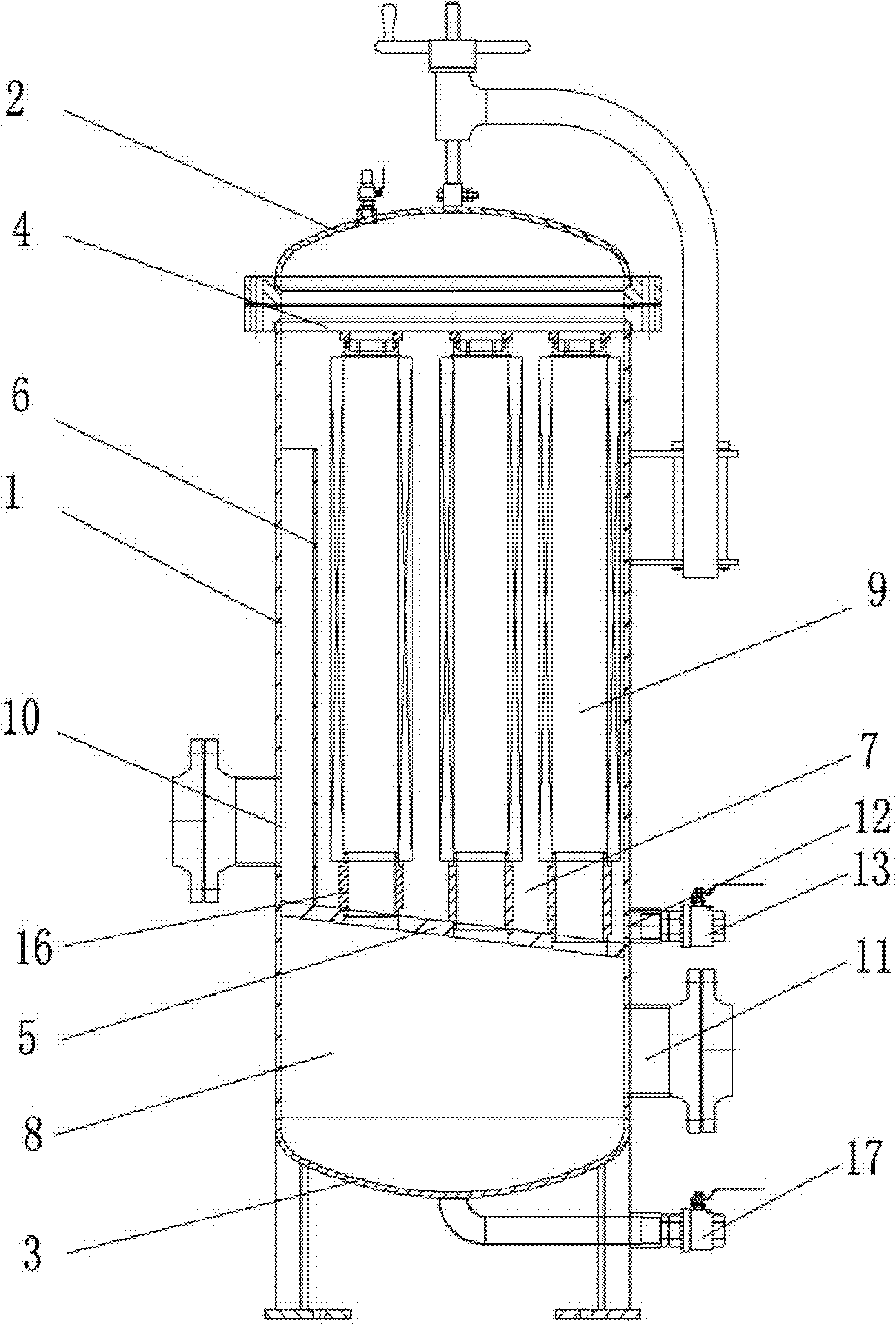

[0022] Such as image 3 , Figure 4 As shown, the second embodiment of the present invention has the characteristics of the first embodiment, wherein the tube sheet 5 is provided with a vertical anti-shock plate 6 between the filter element 9 and the liquid inlet 10, and the anti-shock plate 6 connects the filter area 7 It is divided into a diversion area 14 and a working area 15 connected at the top.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com