Multifunctional closestool

A multi-functional toilet technology, applied in the field of sanitation facilities, can solve the problems of labor cost, ineffective sewage discharge, easy clogging, etc., and achieve the effect of wide flushing range, excellent sewage discharge effect, and not easy to clog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

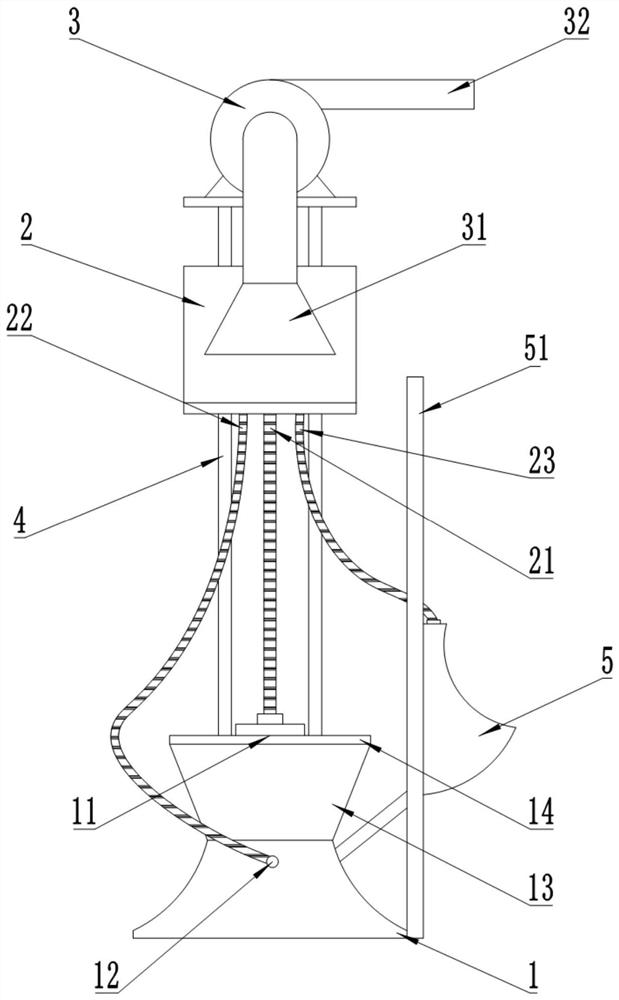

[0036] like figure 1 As shown, the present embodiment provides a multifunctional toilet, including a toilet 1, a water tank 2, an exhaust fan 3 and a bracket 4, the bracket 4 is a steel structure bracket 4, and the toilet 1, the water tank 2 and the exhaust fan 3 are respectively fixed to the bracket 4. The lower, middle and upper parts. The water tank 2 is located 1 meter above the toilet 1. The bottom of the water tank 2 is provided with a first pipeline 21, a second pipeline 22 and a third pipeline 23 respectively. The button for the water outlet of the second pipeline 22 and the third pipeline 23. The exhaust fan 3 is arranged on the top of the water tank 2, and the exhaust fan 3 includes an air inlet pipe 32 and an air exhaust pipe 33. Driven by the motor, the air is sucked by the air inlet pipe 32 and discharged from the exhaust pipe 33.

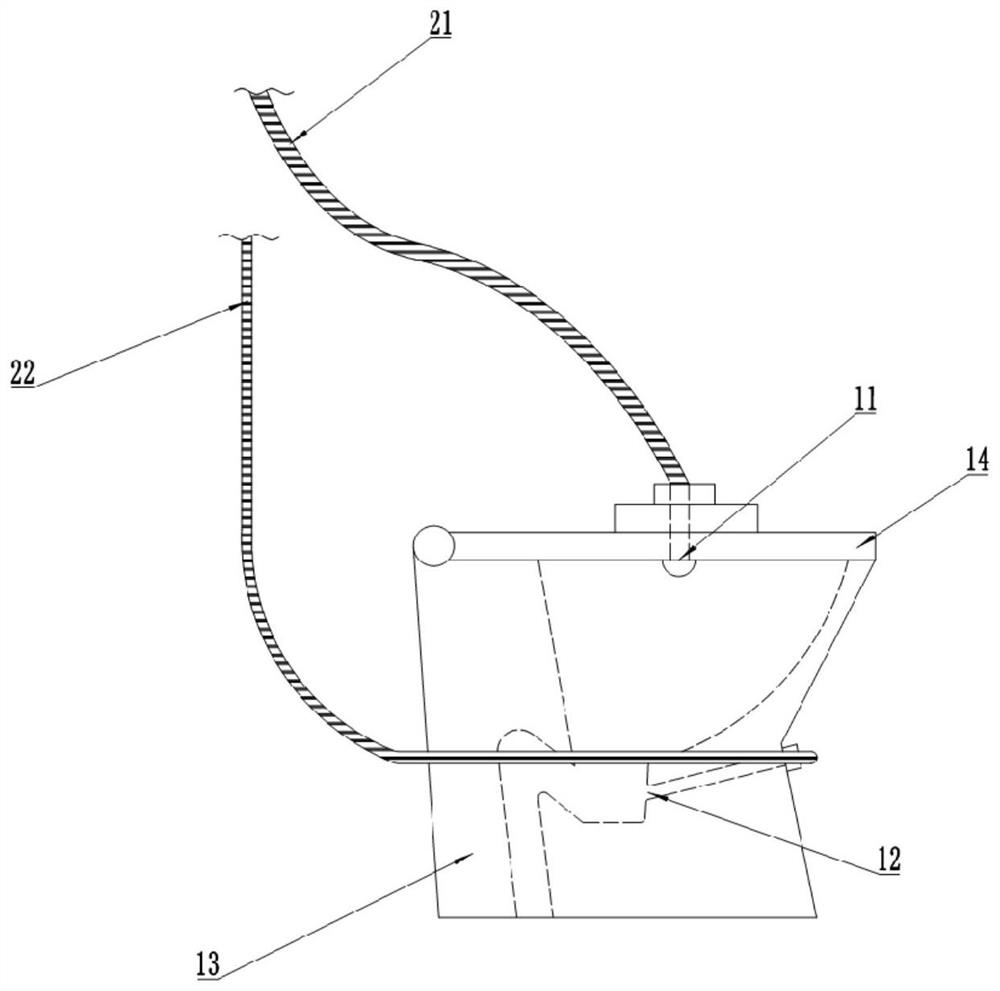

[0037] like figure 2 As shown, the sewer pipe of the toilet 1 is a siphon type pipe. The toilet 1 includes a bucket body 13 and a...

Embodiment 2

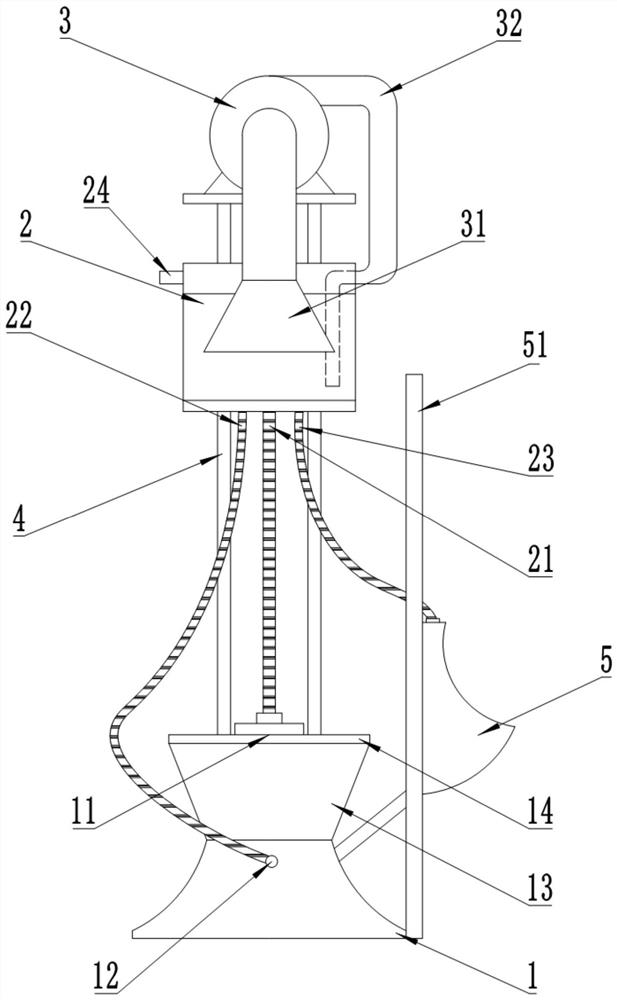

[0043] like image 3 As shown, the difference between the second embodiment and the first embodiment is that the exhaust pipe 33 of the exhaust fan 3 extends downward and extends below the liquid level in the water tank 2. The top of the water tank 2 is also provided with an air outlet 24. The air outlet 24 is of an electronically controlled opening and closing type, and the air outlet 24 is also provided with an activated carbon filter, which can filter the gas discharged from the air outlet 24 . A solid toilet-cleaning block is placed in the water tank 2 , and the main components of the solid toilet-cleaning block include hydrochloric acid (or adipic acid) and fragrance, and an air pressure sensor is also installed in the water tank 2 . The front of the men's urinal 5 is provided with an infrared sensor, which can perform infrared induction automatic flushing. The rest of the structure is the same as that of the first embodiment.

[0044] The use process of this embodiment...

Embodiment 3

[0048] like Figure 4 As shown, the difference between the third embodiment and the second embodiment is that the toilet 1 is also provided with a toilet paper processing bucket 6, the toilet paper processing bucket 6 is cylindrical, and the bucket usually contains water that accounts for one-third of the volume, and the top It is semi-closed and is provided with a flip cover 63, and the area of the flip cover 63 is about one-third of the area of the top. A first spout 61 is provided at the top center of the toilet paper processing bucket 6, and a second spout 62 is provided on the bottom side wall. The bottom of the water tank 2 is also provided with a fourth pipeline 25. The fourth pipeline is a three-way pipeline, which is respectively connected to the bottom of the water tank 2, the first spout 61 and the second spout 62, and the fourth pipeline 25 passes through the first spout. 61 and the second spout 62 are respectively fixed at the top and bottom positions of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com