Closestool with pressurizing drainage device

A technology for drainage devices and toilets, which is applied in water supply devices, flushing toilets, sanitary equipment for toilets, etc. It can solve the problems that affect the water-saving performance of siphon toilets, poor water-saving effects, and large water consumption, and achieve sewage discharge The effect is strengthened, the effect of sewage discharge is obvious, and the effect of saving water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

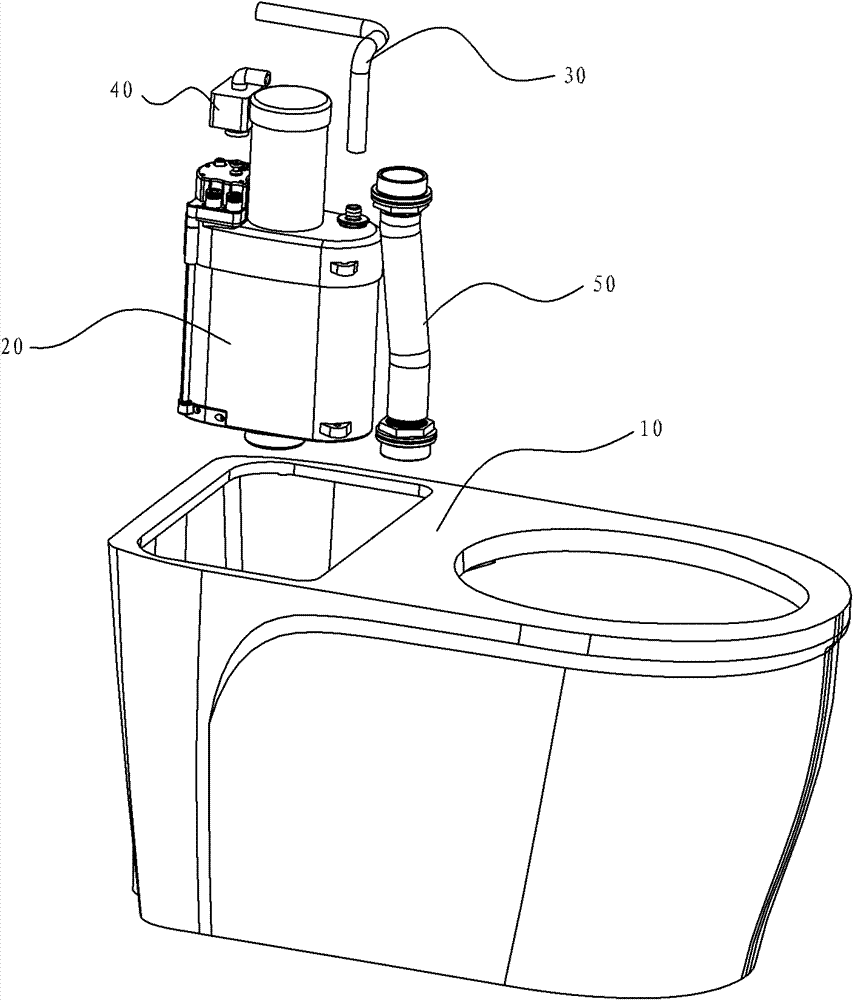

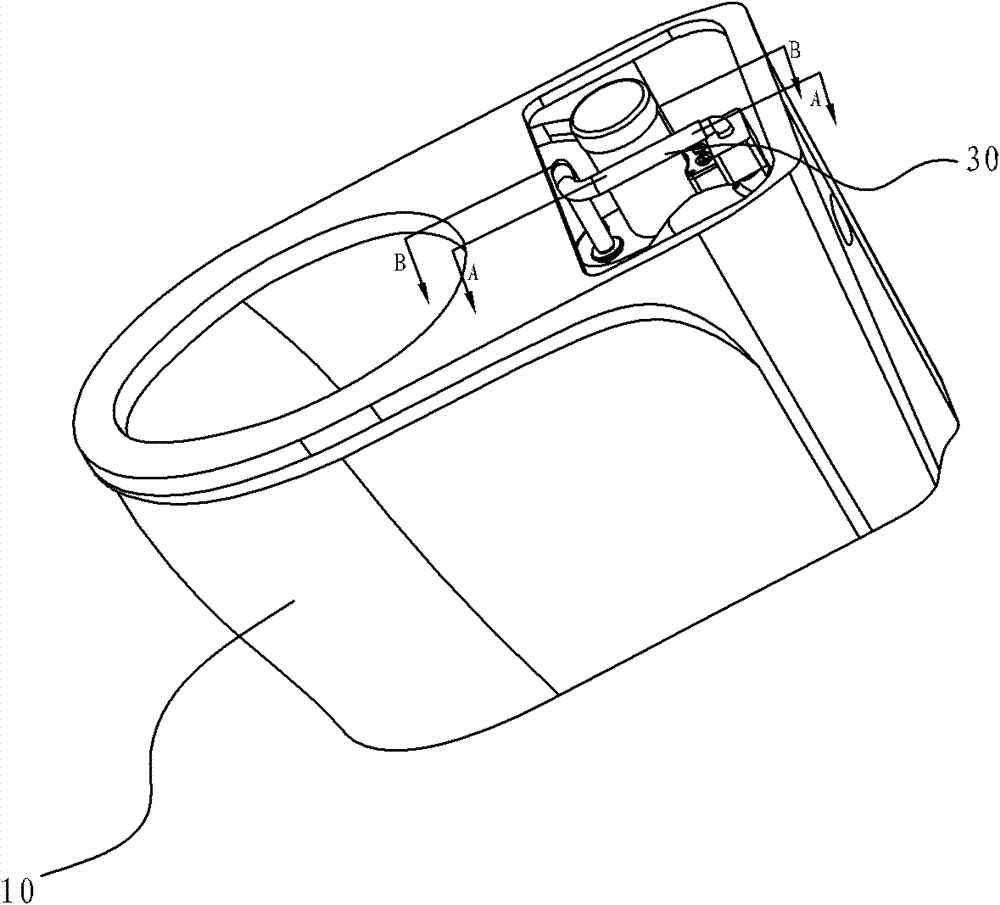

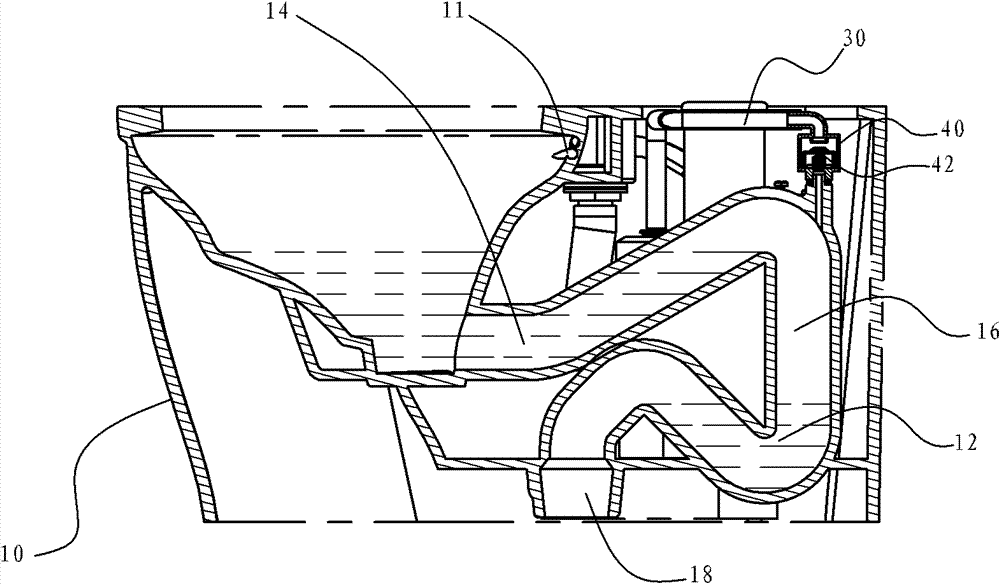

[0028] Such as figure 1 , figure 2 , image 3 As shown, the toilet with a pressurized drainage device according to the present invention includes a toilet body 10 and a pressurized drainage device; the toilet body 10 is provided with a ring washing nozzle 11, an upper trap 14, a lower trap 12, Gas storage pipeline 16, sewage outlet 18, gas delivery pipe 30, gas storage pipeline 16 is located between the upper water trap 14 and the lower water trap 12, and communicates with the upper water trap 14 and the lower water trap 12, the sewage outlet 18 communicates with the lower water trap 12, and the gas delivery pipe 30 communicates with the gas storage pipeline 16.

[0029] Such as image 3 , Figure 4 , Figure 5 As shown, the pressurized drainage device includes a box body 20 and a water inlet and outlet mechanism and a pressure mechanism located in the box body 20. The water inlet and outlet mechanism includes a water inlet pipe 27, a drain switch 23 and a drain valve 29...

no. 2 example

[0033] Such as Image 6 , Figure 8 , Figure 9 As shown, the difference between this embodiment and the first embodiment is that the upper end of the box body 20 is also provided with a second air port 31'. The installation position of the second air port is not limited to this, and it can also be installed on the air pipe or on the buffer. The front end; the second air port 31' is provided with an air supply check valve 60 and an air port spring 62, the air supply check valve 60 is used to control the air entering the second air port 31', and the air port spring 62 is arranged under the air supply check valve 60 and in a preloaded state.

[0034] Such as image 3 , Figure 7 , Figure 8As shown, when the second chamber 25 of the box body 20 enters water through the water inlet pipe 27, the piston assembly 21 moves upward, the space of the first chamber 24 becomes smaller, the space of the second chamber 25 becomes larger, and the first chamber The air in the chamber 24...

no. 3 example

[0036] Such as Figure 10 , Figure 11 , Figure 12 As shown, the difference between this embodiment and the first embodiment is that the upper end of the box body 20 is also provided with a second air port 31', and the second air port 31' is provided with an exhaust check valve 60, which is used for exhaust check valve 60. In order to control the discharge of air from the box body 20 , the first air port 31 is provided with an air suction one-way valve 70 , and the air suction one-way valve 70 is used to control air entering the box body 20 from the air delivery pipe 30 .

[0037] Such as image 3 , Figure 11 As shown, when the second chamber 25 of the box body 20 enters water through the water inlet pipe 27, the piston assembly 21 moves upward, the space of the first chamber 24 becomes smaller, the space of the second chamber 25 becomes larger, and the first chamber The air in the chamber 24 is compressed, and both the exhaust one-way valve 60 and the suction one-way va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com