Chain Brake Equipment

A technology of braking equipment and equipment, applied in the direction of ships, etc., can solve the problems of hydraulic system damage, strong waves, etc., and achieve the effect of avoiding transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

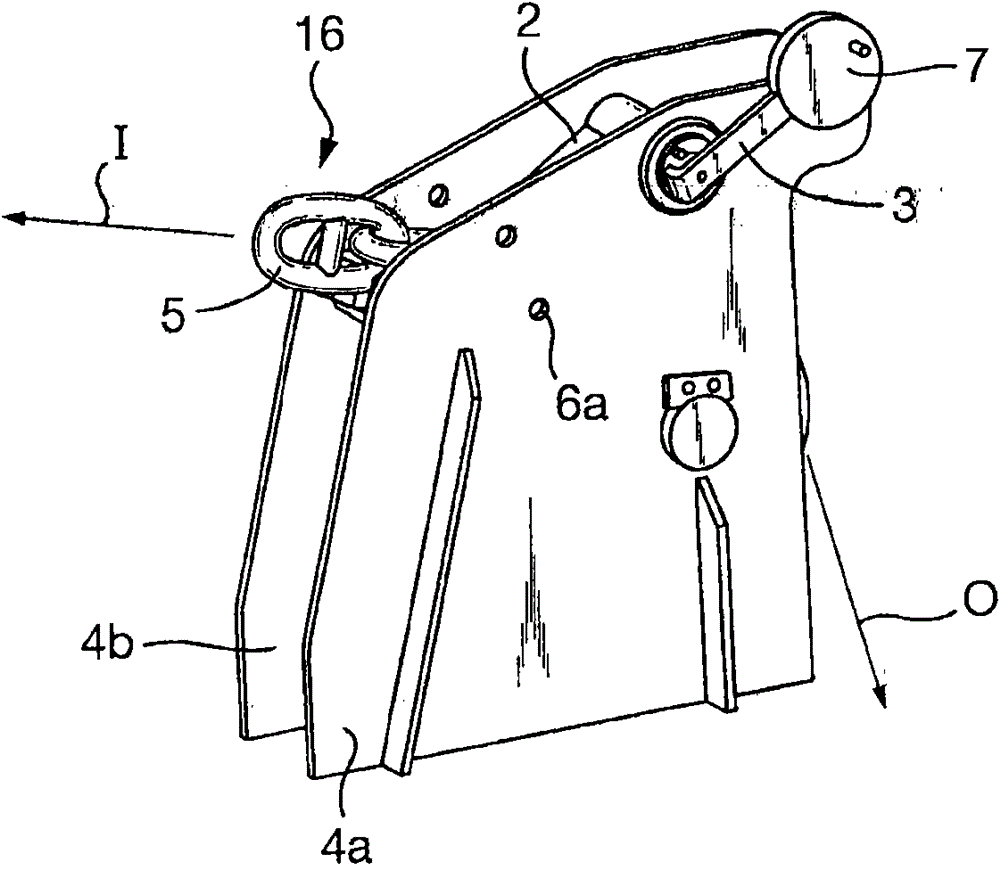

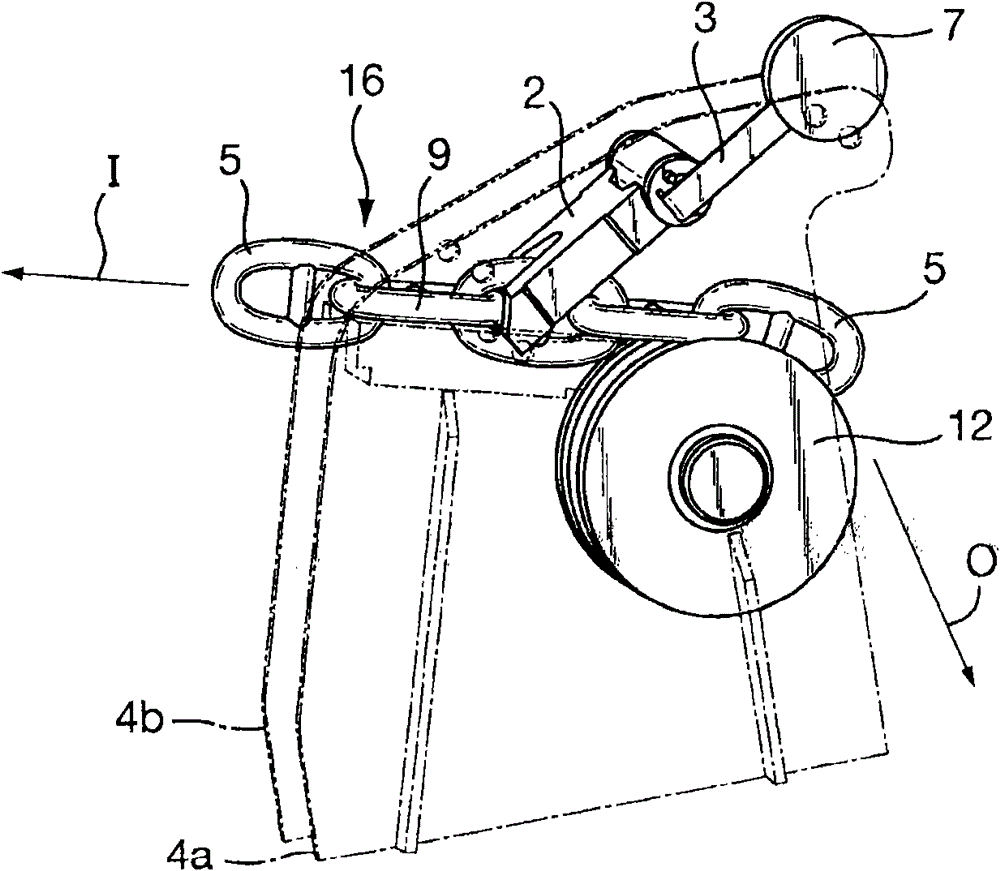

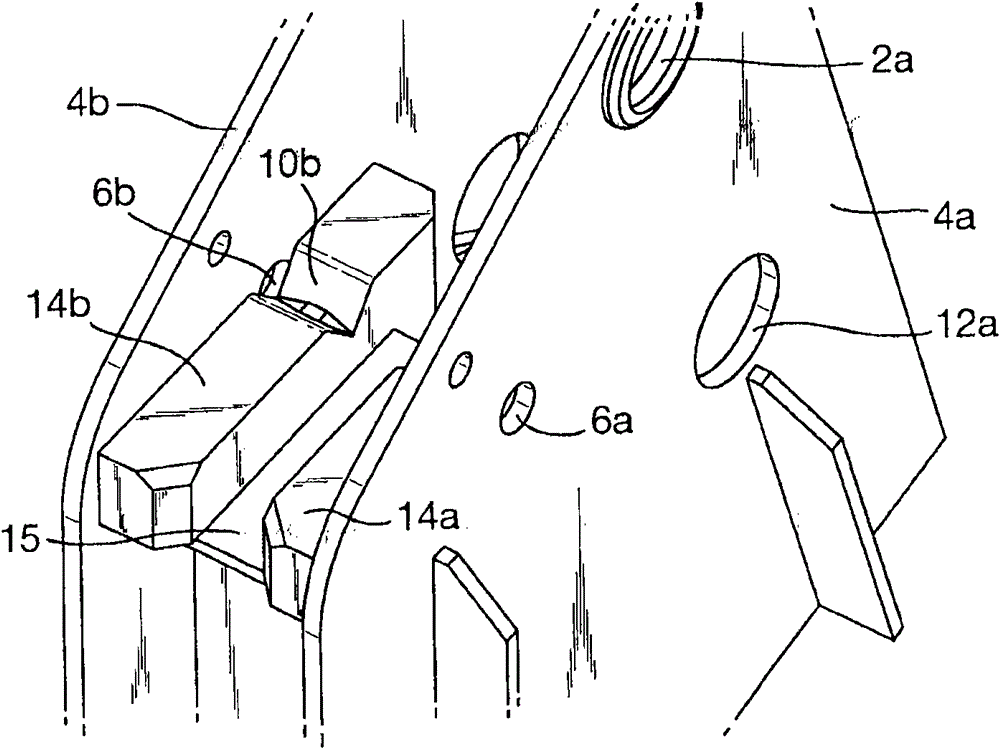

[0031] Referring to the attached drawings, first of all figure 1 with figure 2 , the chain braking device according to the invention comprises a frame which in the described embodiment consists of two upstanding plate elements 4a, 4b which are attached at their lower ends to the deck of the ship by conventional means ( not shown). This device replaces conventional chain brakes and is therefore welded to the deck between the windlass and the hawse barrel. Anchor chain 16 (only a portion of which is shown) extends through the chain braking apparatus, in the inboard direction towards the winch (not shown), indicated by the arrow marked "I", and in the outboard direction towards the hawse barrel ( not shown) and the sea, shown by the arrow marked "O". Thus, when the anchor chain is released from the ship, it moves in the "O" direction, and when it is pulled back, for example in connection with the lifting of the anchor, the chain moves in the "I" direction. These operations a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com