Waste heat absorbing kettle for gas stove

A technology for gas stoves and kettles, which can be used in household heating, water heaters/stoves, applications, etc., and can solve problems such as discomfort, fluttering heat, instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

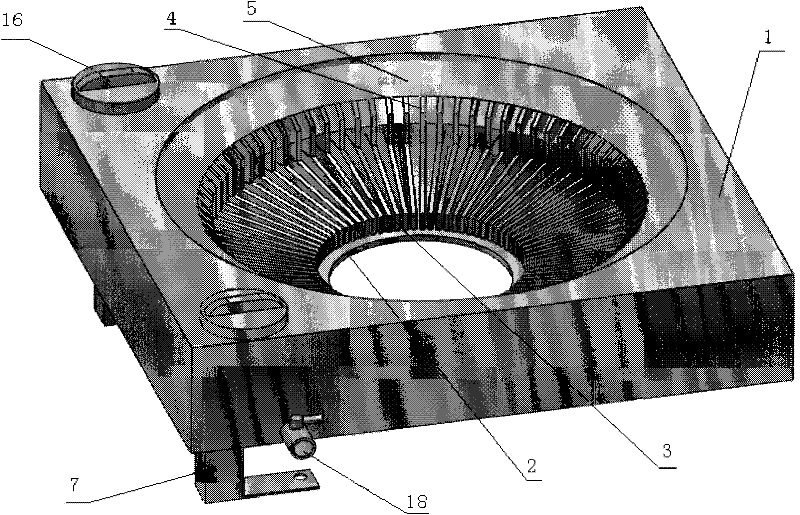

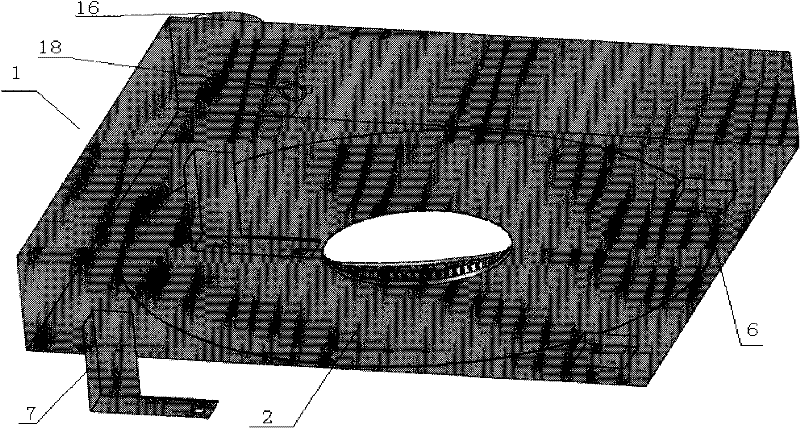

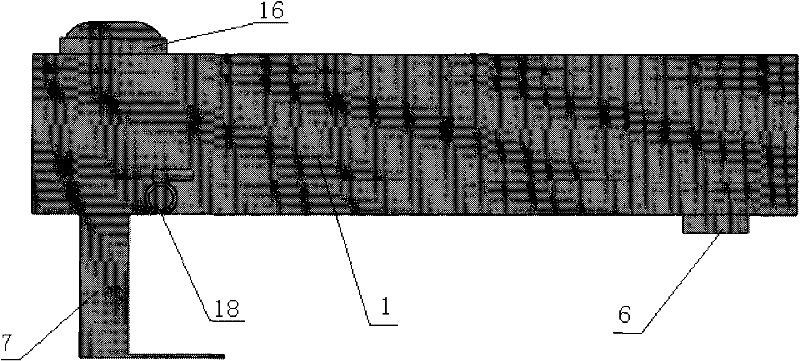

[0035] Gas cooker of the present invention is used as the residual water absorption kettle such as Figure 1 to Figure 16 shown.

[0036] A waste-absorbing kettle for a gas stove, its annular water tank (1) surrounds the flame of the burner of the gas stove in a ring shape, such as Figure 16 As shown, the annular water tank (1) can surround the flame in 360 degrees.

[0037] The inner surface lower part (11) of annular water tank (1) resembles the side shape of the similar circular truncated body, as Figure 5 , Image 6 , Figure 7 As shown, the flame heat of the gas stove can be heated from the bottom of the annular water tank (1), facilitating the formation of heat convection from the bottom to the top of the water body; The shape is similar to the arc shape of the side of the frying pan, which helps the side and inner surface top (12) of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com