Novel steam atomization device

An atomizing device and steam technology, which are applied in washing devices, steam generation, steam generation methods, etc., can solve the problems of difficult processing, inconvenient processing, and cumbersome use of irons, and achieve good atomization effect, low cost, and ease of use. processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

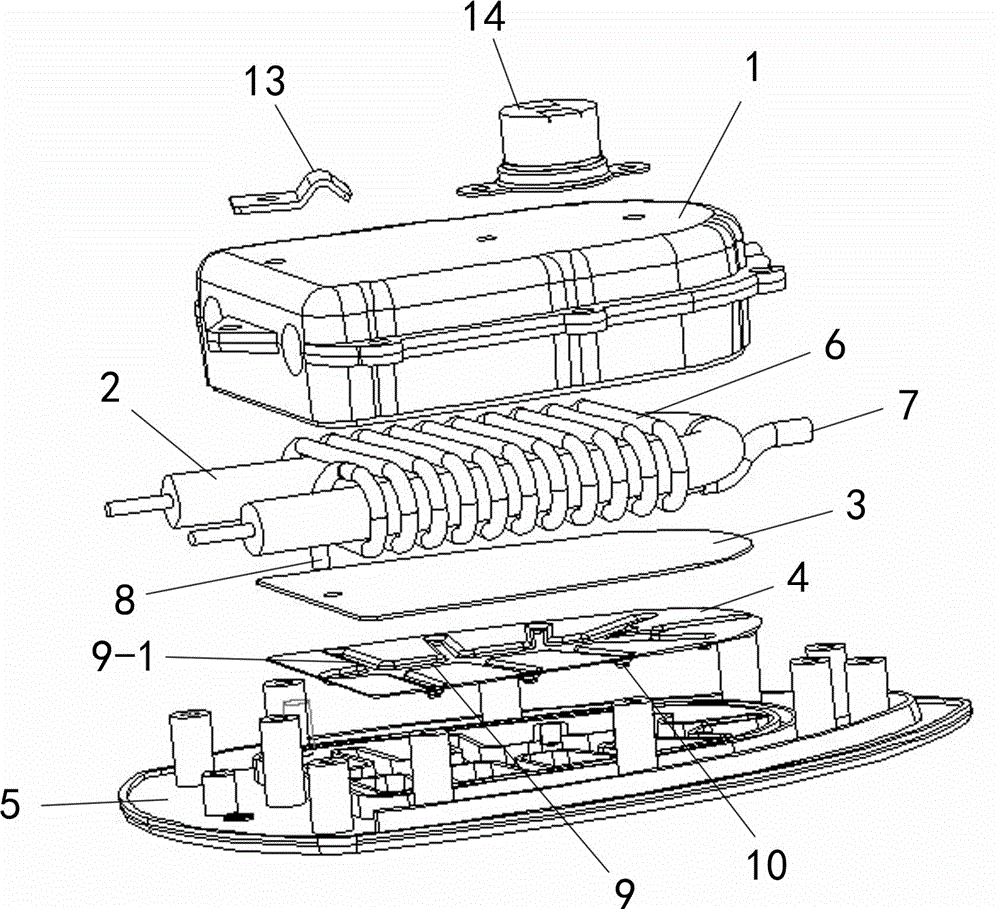

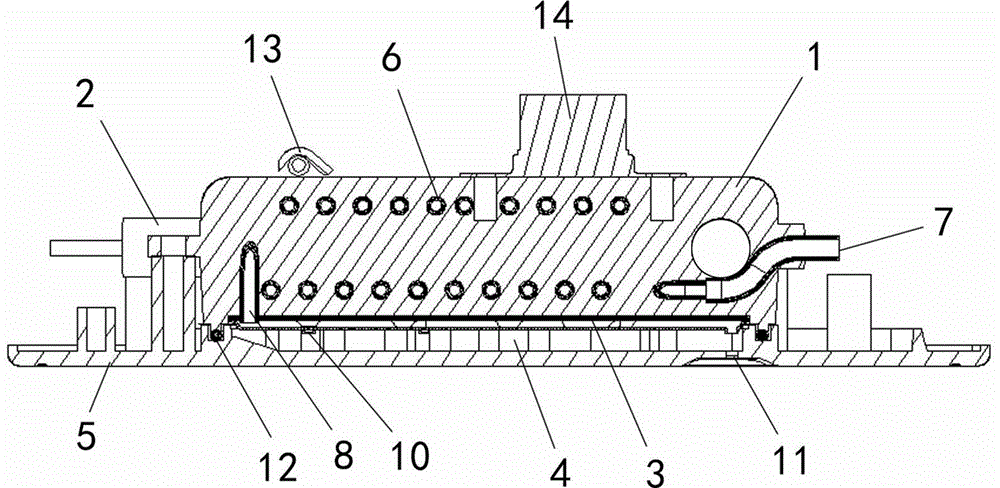

[0012] Such as figure 1 , figure 2 As shown, a new steam atomization device is characterized in that it includes an aluminum heating body 1, a heating pipe 2, a heat conducting plate 3, a steam circulation plate 4 and an iron soleplate 5, and the heating pipe 2 is built in the aluminum heating body 1, The heat pipe 2 is wound with a steam channel 6, one end of the steam channel 6 is a water inlet 7, and the other end is a steam outlet 8; the bottom of the aluminum heating body 1 is die-cast with a heat conduction plate 3, and the bottom surface of the heat conduction plate 3 is provided with a steam circulation plate 4. The steam circulation plate 4 is provided with a steam flow groove 9, and the steam flow groove 9 is provided with several branch grooves 9-1, and the end of the branch groove 9-1 is provided with a steam outlet 2 10, and the heat conduction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com