High-reliability capacitance type radio frequency micro-electromechanical system switch without charge injection effect

A technology of charge injection effect and micro-electromechanical system, applied in the direction of electric switch, magnetic/electric field switch, circuit, etc., can solve the problems of reducing the amount of charge injection, low-frequency noise, and small dielectric constant, and achieve the goal of improving reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

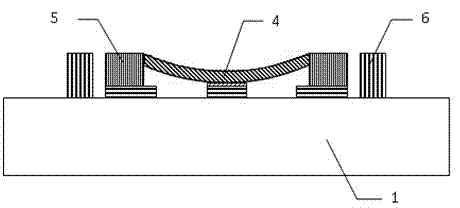

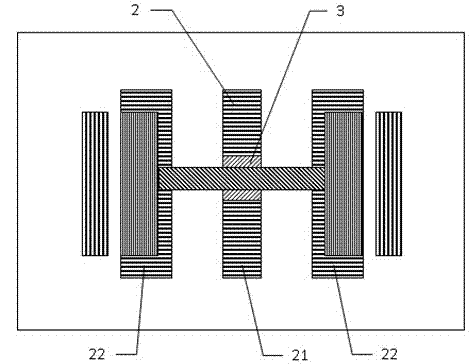

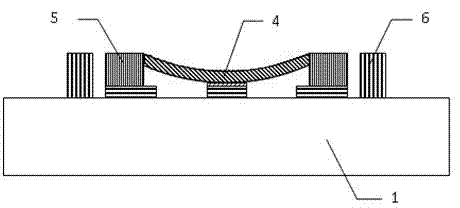

[0011] Example: Such as figure 1 , figure 2 As shown, the manufacturing process of the capacitive radio frequency MEMS switch of the present invention comprises the following steps:

[0012] (1) Sputter gold on a low-loss substrate and etch to form a coplanar waveguide;

[0013] (2) Deposit a layer of insulating dielectric film and etch only the part covering the overlapping area between the center electrode of the coplanar waveguide and the membrane bridge;

[0014] (3) Coating a sacrificial layer, and etching a movable bias electrode window on the sacrificial layer;

[0015] (4) Sputter gold and etch to form membrane bridges and movable bias electrode patterns, and then perform soft gold electroplating to thicken to form membrane bridges and movable bias electrode structures;

[0016] (5) Coat the sacrificial layer again, cover the film bridge and the movable bias electrode, and etch the fixed bias electrode window on the sacrificial layer;

[0017] (6) Sputter gold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com