Chassis of railway bathtub open wagon

A vehicle chassis and bathtub technology, which is applied to railway car body parts, chassis, transportation and packaging, etc., can solve the problems of bathtub end plate deformation, reduced service life, and increased longitudinal impact force, etc., to reduce weight and improve Service life, effect of reducing longitudinal impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

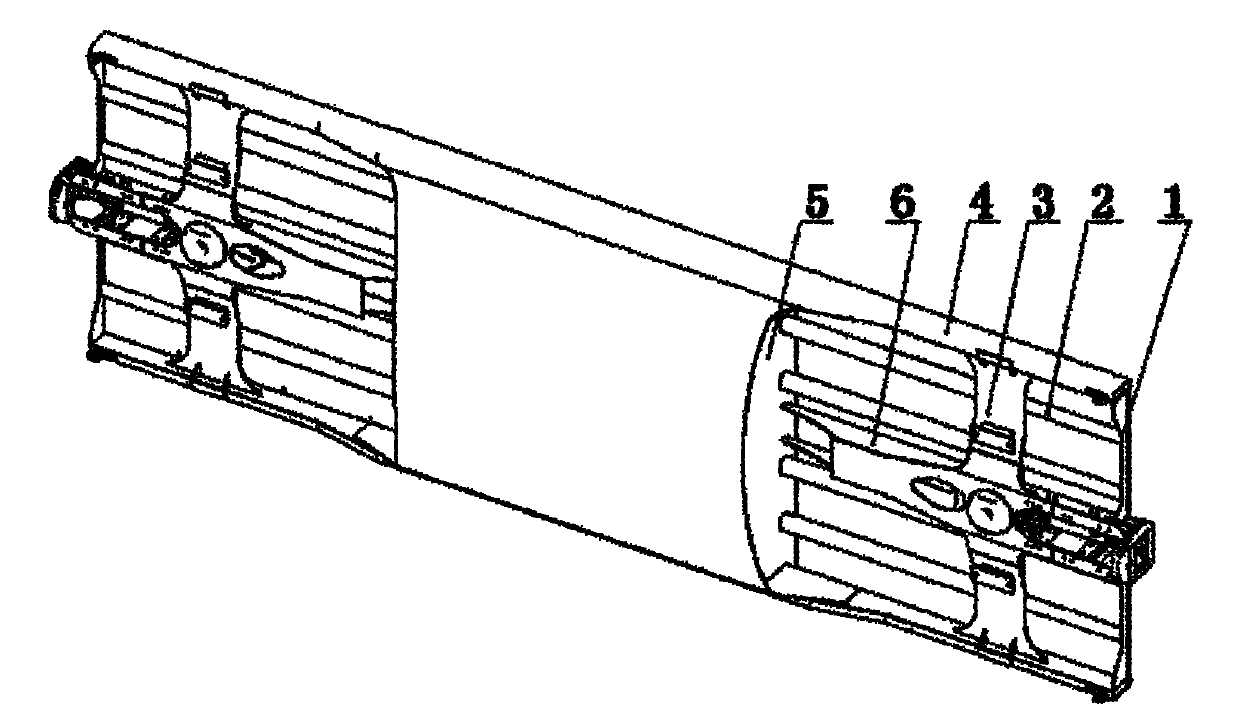

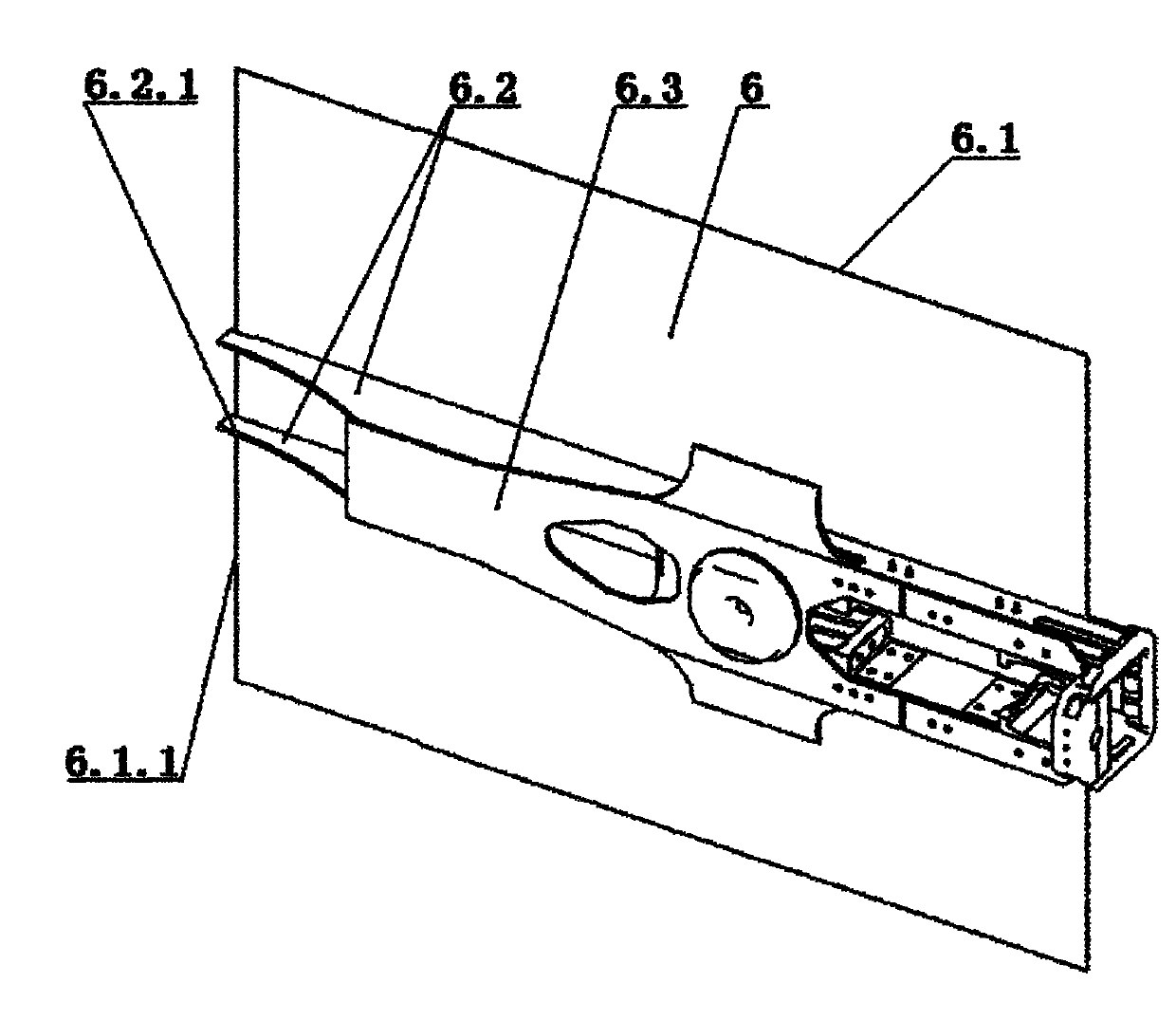

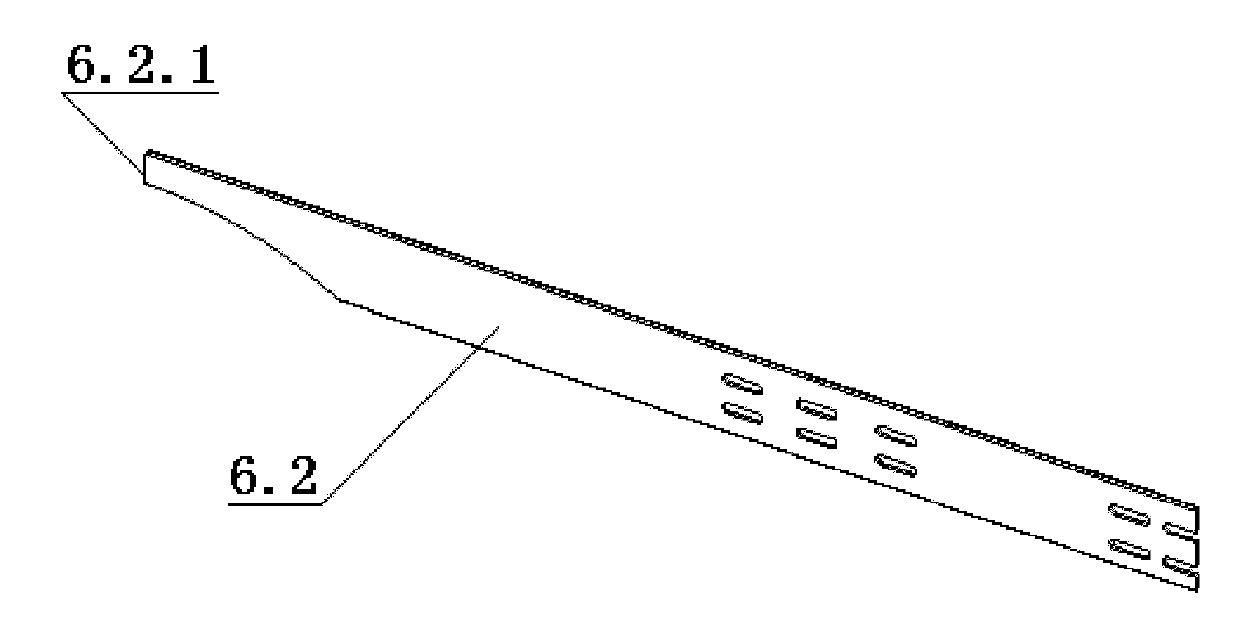

[0013] Embodiment: end beam assembly 1, longitudinal beam 2, corbel assembly 3, side beam assembly 4, bathtub 5 composed of bottom plate 5.1 and end plate 5.2, and upper cover plate 6.1 in box-type traction beam 6 are all Made in a conventional way, the web tail end 6.2.1 of the web 6.2 in the box-type traction beam 6 is a variable-section structure with a section gradually increasing from the outside to the inside, and the length of the lower cover plate 6.3 is the same as the plane of the lower end of the web 6.2. The lengths are consistent, and the upper cover plate tail end 6.1.1 and the web plate tail end 6.2.1 of the upper cover plate 6.1 are all welded and connected with the end plate 5.2 to become the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com