Workpiece classification discharge system and workpiece classification discharge method

A technology for workpieces and discharge pipes, which is applied in the manufacture of electrical components, electrical components, semiconductors/solid-state devices, etc., can solve problems such as cost increases, and achieve the effect that the discharge processing speed will not decrease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

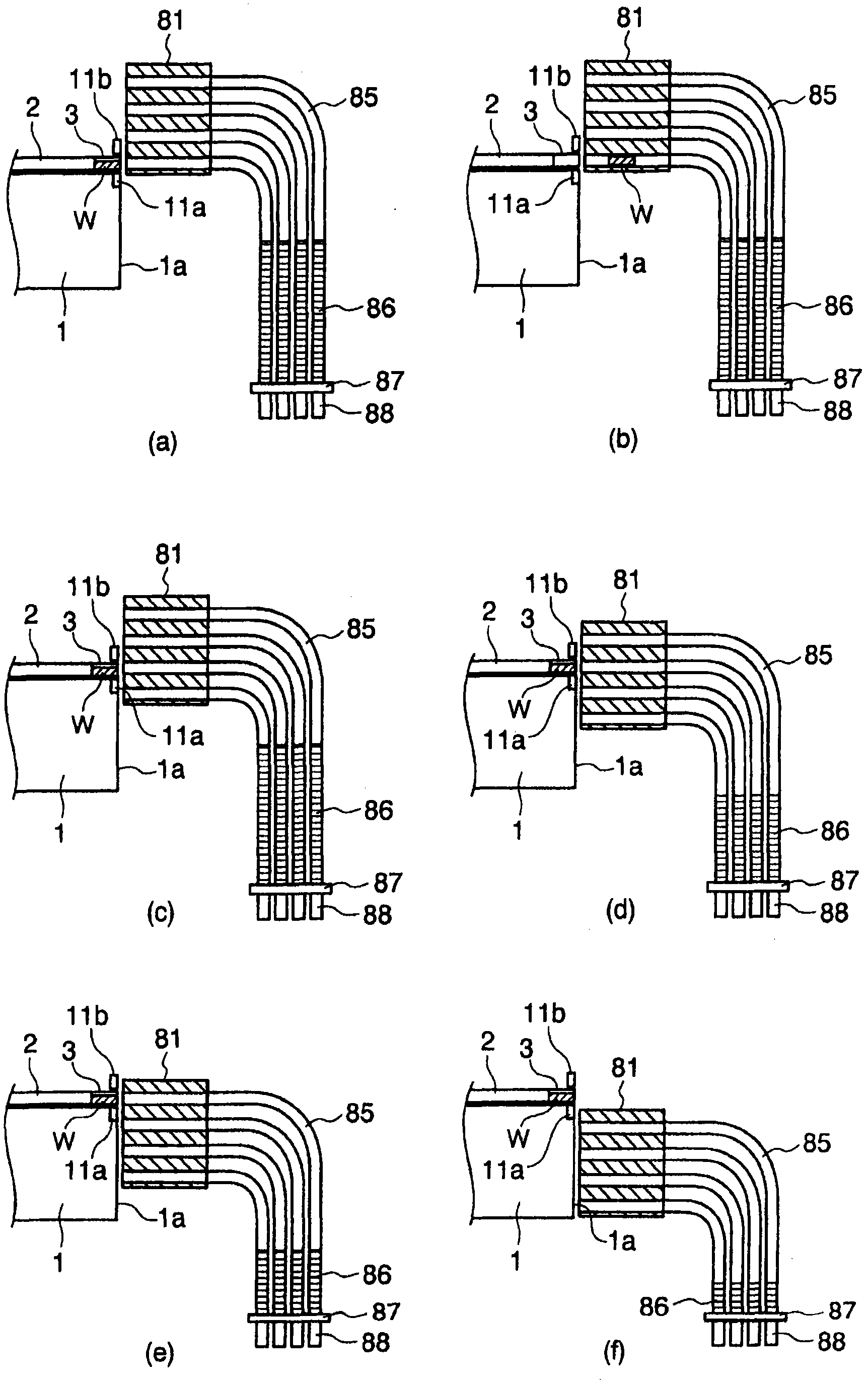

[0082] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

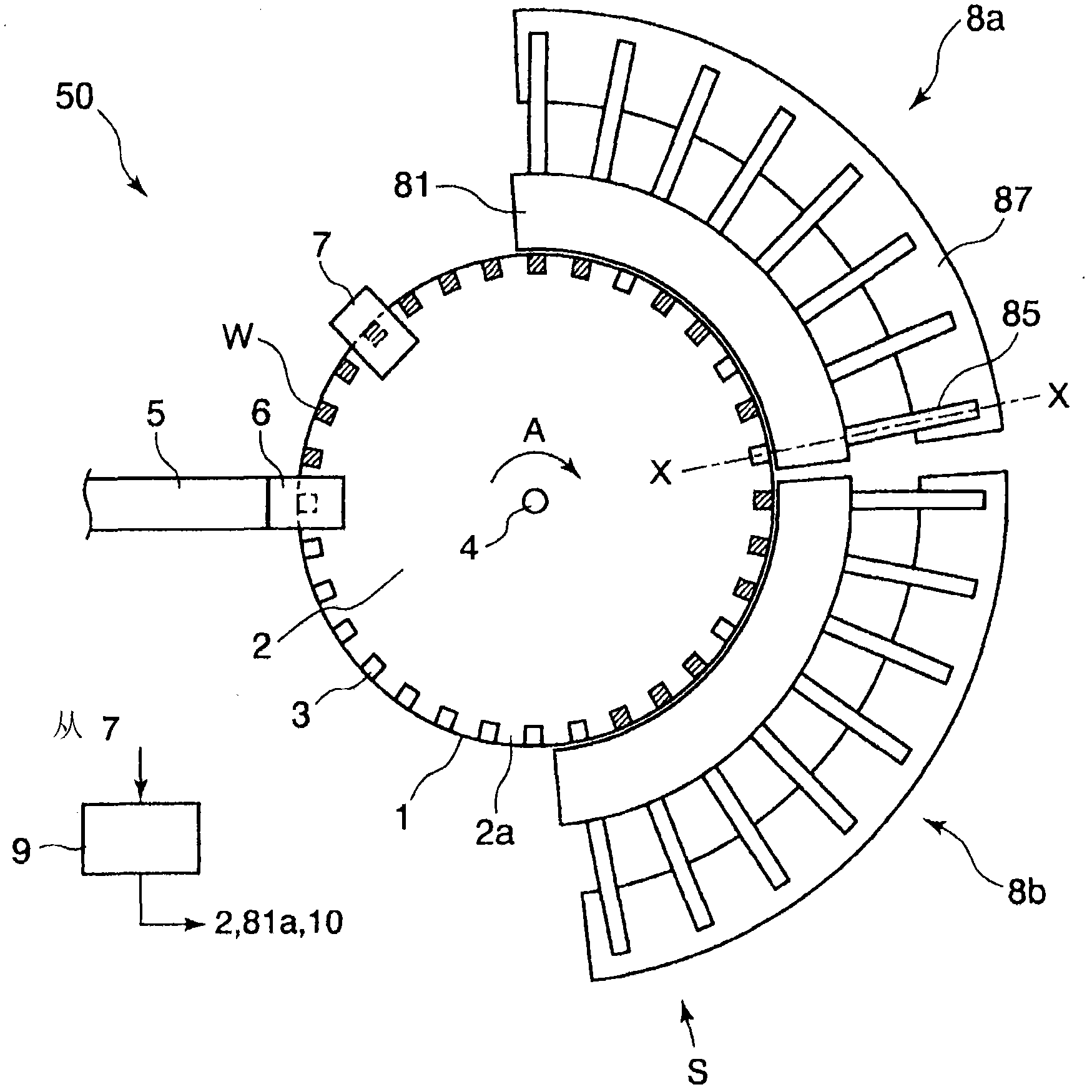

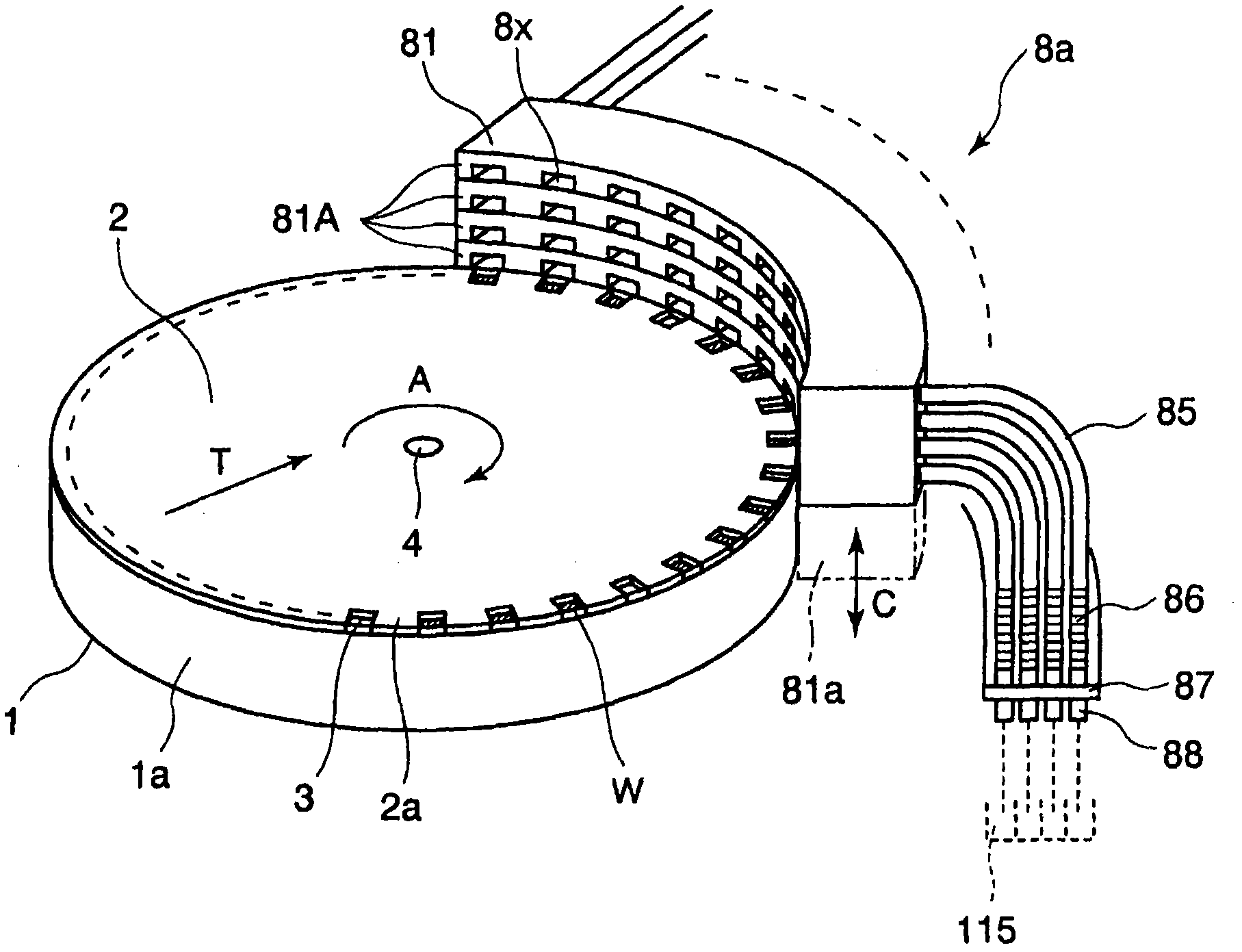

[0083] Figure 1 to Figure 29 It is a figure which shows one Embodiment of the workpiece sorting and discharging system and the workpiece sorting and discharging method of this invention.

[0084] here, figure 1 is a plan view showing the workpiece sorting and discharging system, figure 2 It is a perspective view showing the workpiece sorting and discharging system.

[0085] Such as figure 1 and figure 2 As shown, the workpiece sorting and discharging system 50 includes: a pedestal 1 disposed in the horizontal direction and having an outer peripheral surface 1a; The workpiece storage hole 3 that is open outward and accommodates the workpiece W; and the workpiece measurement unit 7 are provided near the outer peripheral portion 2a of the transfer table 2, and measure the electrical characteristics of the workpiece W in the workpiece storage hole 3.

[0086] and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com