Device and method for thermally bonding a flexible coating to a support

A support, thermal bonding technology, applied in special positions, applications, household appliances, etc. of vehicles, can solve problems such as deterioration of personnel working conditions, economic losses, and rising ambient temperature, and achieve simple and effective implementation and rapid adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

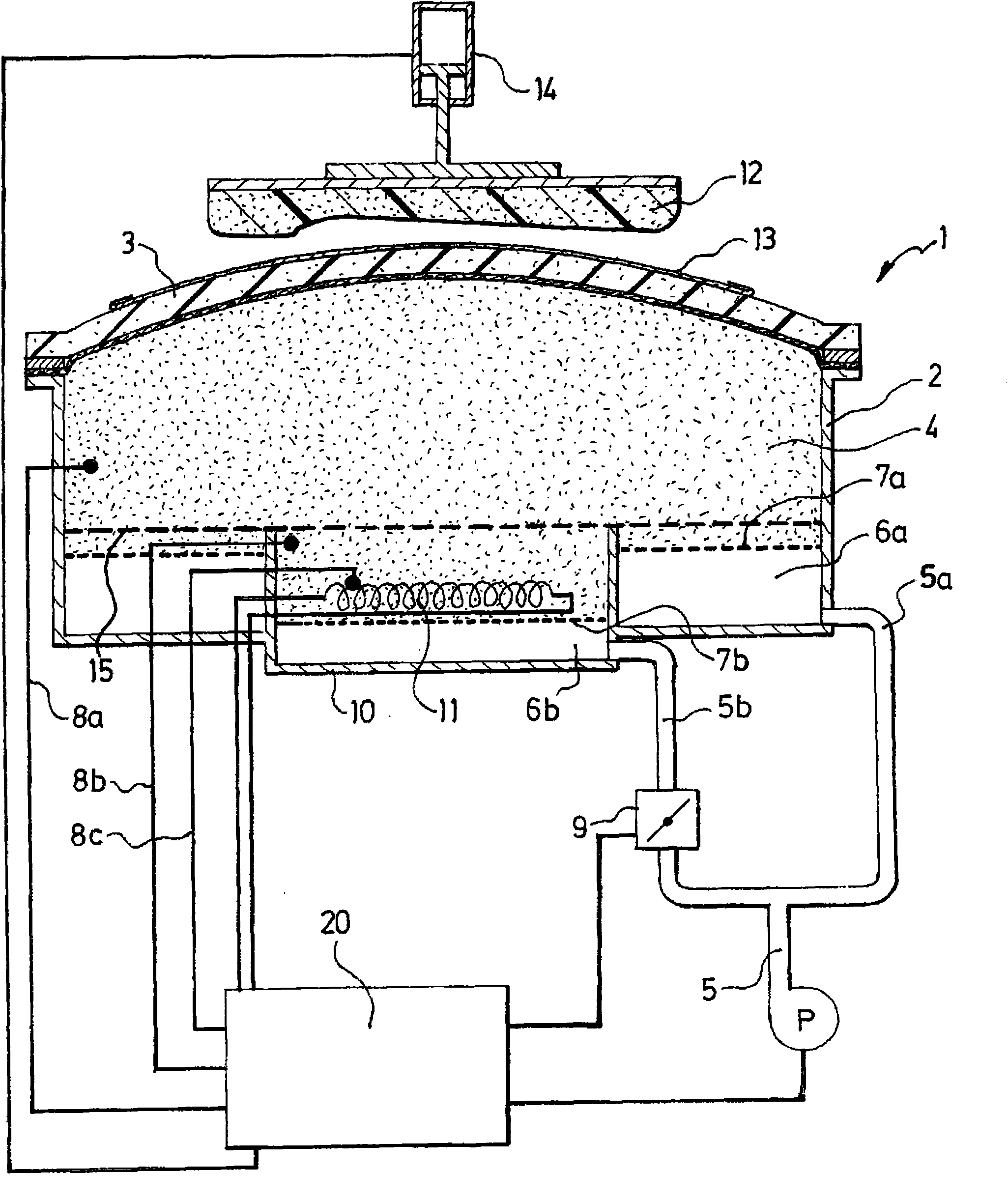

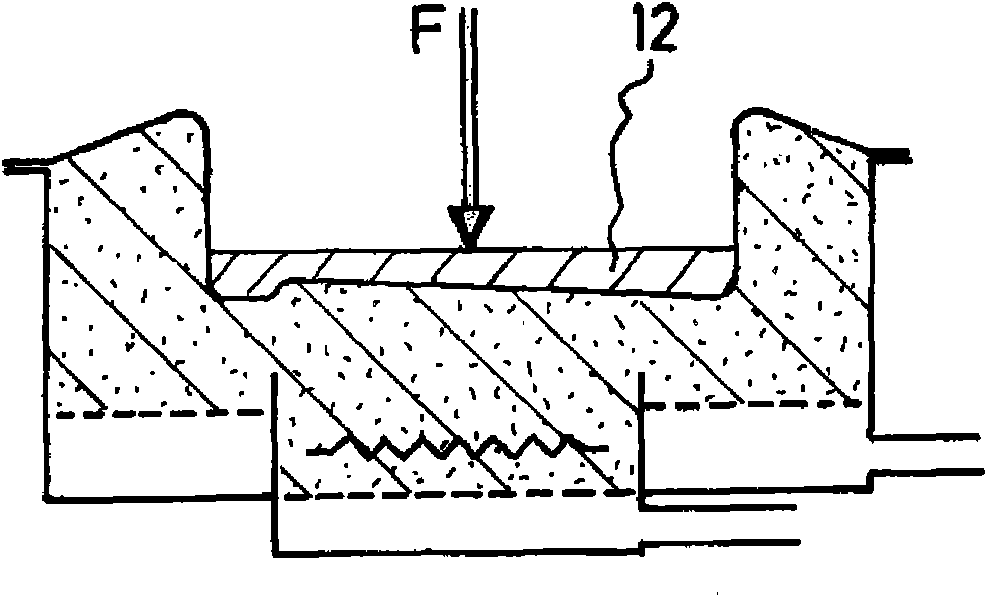

[0039] by figure 1 The device according to the invention shown in the example in the example, also known as the skin processing table, is of the aforementioned patent EP 0 350 979 figure 1 The type shown in. It is intended to perform the assembly and bonding of the flexible outer cover to the foam support, for example, to obtain a seat skin.

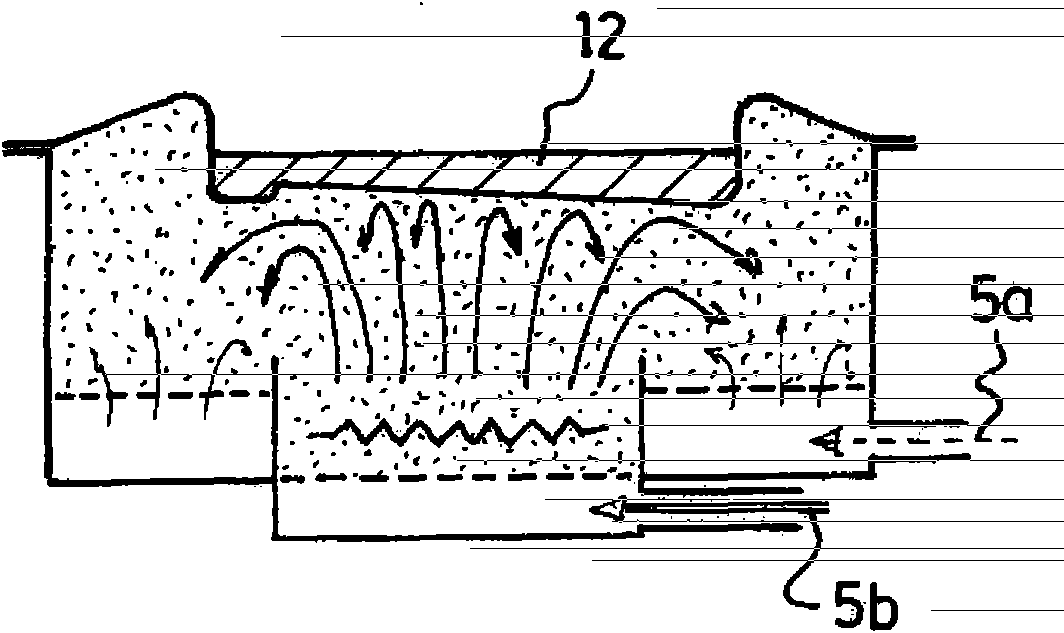

[0040] The device includes a processing table 1 with a parallelepiped housing 2 whose height is smaller than its other dimensions. The housing 2 contains a particle bed 4, which is composed of, for example, glass microspheres having a diameter from 75 to 150 microns, and preferably substantially equal to 100 μm. The particles are placed on the diffusion filter 7a, which is formed of, for example, a microporous pressed wood (pressed wood) sheet adapted to allow from the space located between the diffusion filter 7a and the bottom of the housing 2, also called The gas flow through the gas distributor 6a, while keeping the glass beads in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com