Side cover plate for geotechnical engineering physical model test

A physical model, geotechnical engineering technology, applied in soil material testing, material inspection products, testing of machine/structural components, etc., can solve the problems affecting tunnel, cave excavation, high production cost, heavy workload, etc. To achieve the effect of reducing the test workload and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

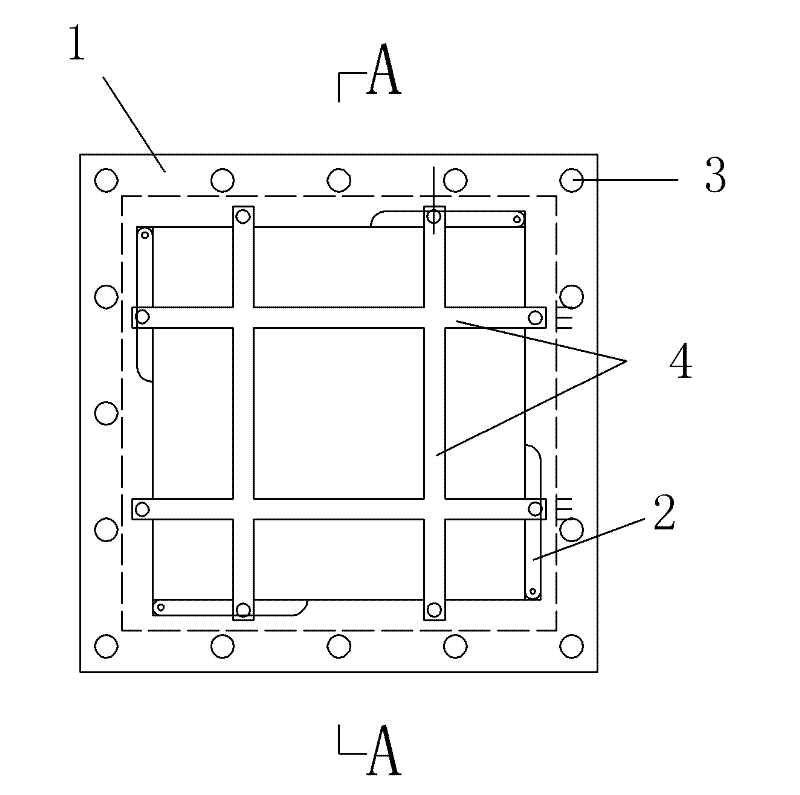

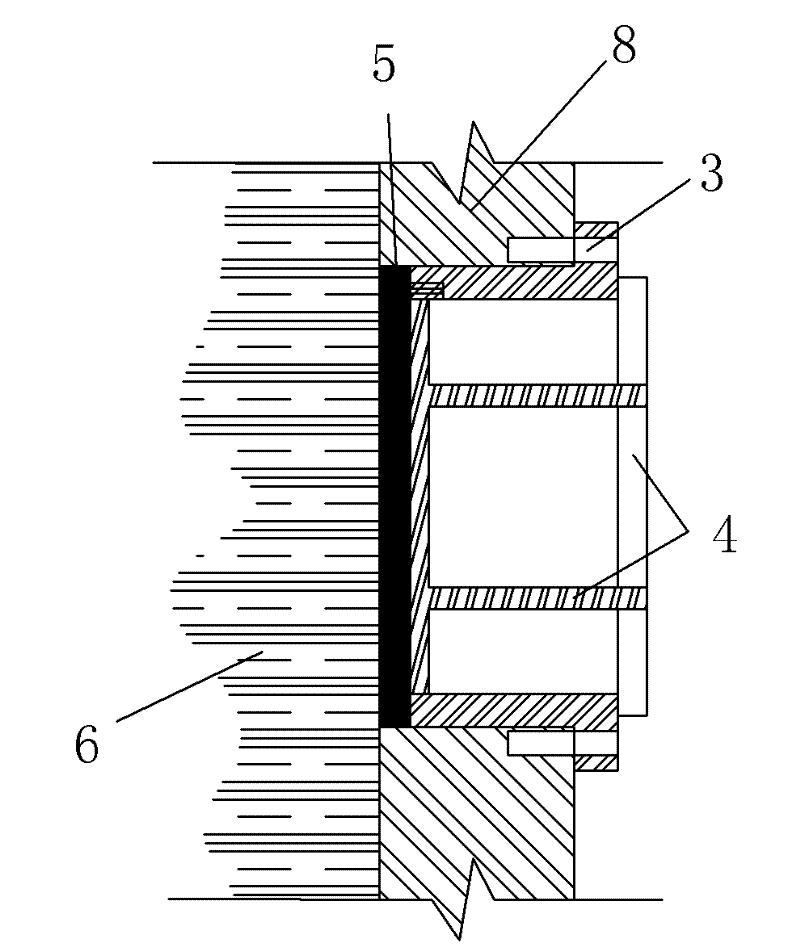

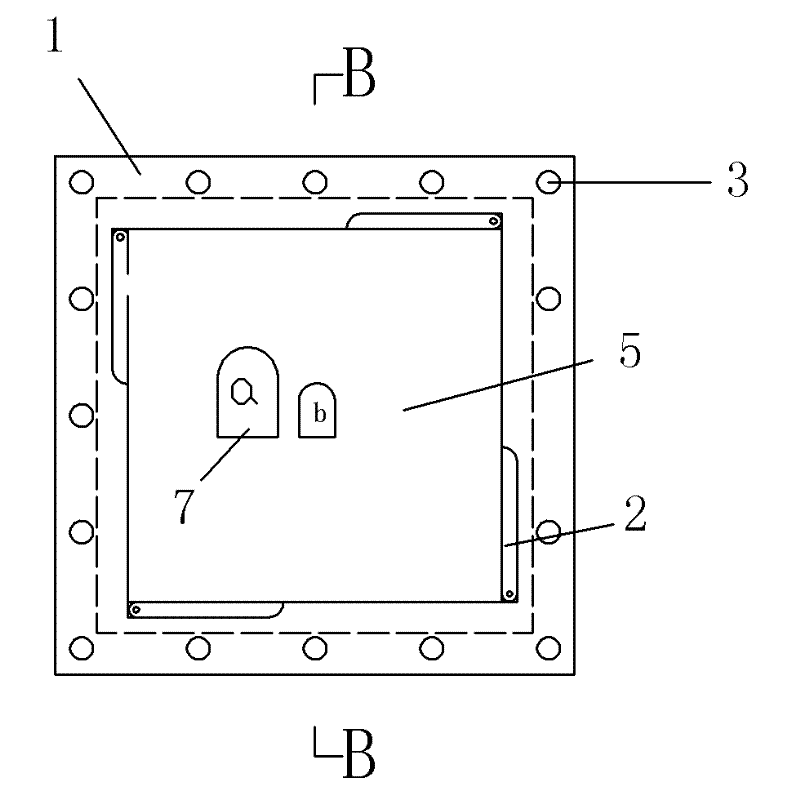

[0023] Such as figure 1 and figure 2 As shown, the side cover plate for geotechnical engineering physical model test of the present invention includes a cover plate main frame 1, a plexiglass plate 5 and a support frame 4, and the plexiglass plate 5 and the support frame 4 are all installed on the cover plate main frame 1, The plexiglass plate 5 is fixed on the inner side of the cover plate main frame 1, the support frame 4 is fixed on the outside of the cover plate main frame 1 by bolts, the outside of the plexiglass plate is in contact with the inside of the support frame, and one end of the stiffener 2 is rotatably connected to the On the main frame of the cover plate, the stiffeners 2 are attached to the outside of the plexiglass plate, and the plexiglass plate 5 is provided with an excavation hole 7 . Stiffeners can be rotated to desired positions as needed and rotated to avoid excavation holes during excavation. A plurality of position adjustment bolts 3 are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com