Camera functional test plate

A functional test and camera technology, which is applied in image communication, television, electrical components, etc., can solve the problems of production efficiency and production cost impact, waste of time and financial resources, etc., and achieve the effect of improving utilization efficiency, avoiding duplication and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

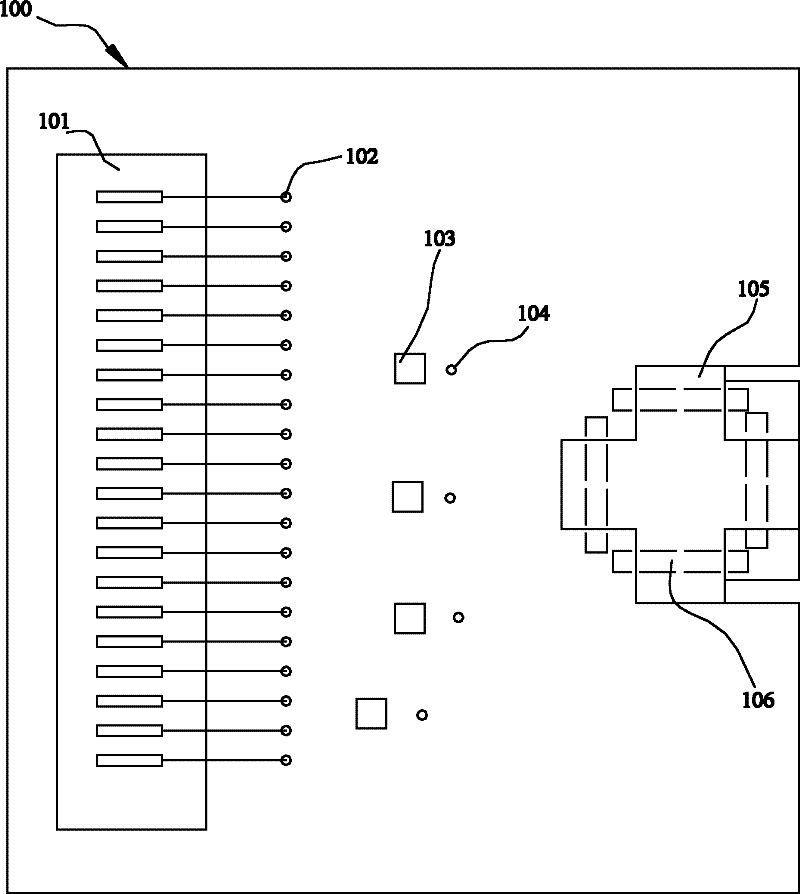

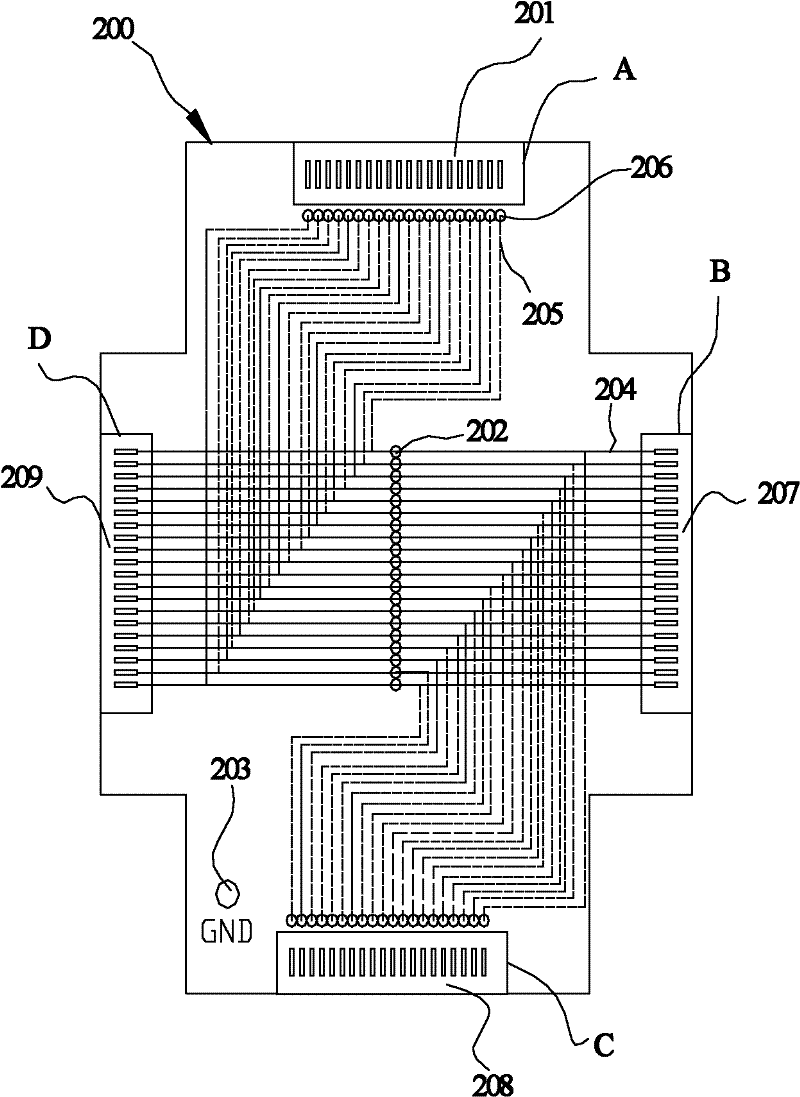

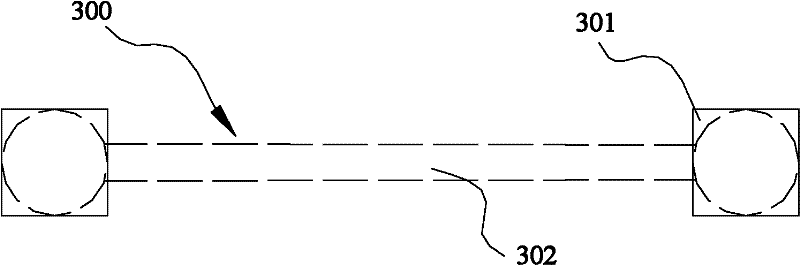

[0021] The core of the camera function test board of the present invention is composed of a large board, a small board and corresponding metal clamping wires, wherein the large board and the small board can be artificially connected at will. In this way, when testing different camera module products, it is only necessary to consider the cooperation between the connector on the small board and the connector of the product under test, without considering the relationship between the product under test and the large board, between the product under test and the small board, or between the product under test and the small board. And the cooperation between the large board and the small board; at the same time, it is also possible to change the horizontal / vertical direction of the connector by rotating the small board or place the small board in the front and back grooves of the large board to be suitable for different camera module products, thus One test board can be used for test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com