A material feeding device for a VSI-crusher, and a method of crushing material.

A feeding device and crusher technology, applied in grain processing, etc., can solve the problems of reducing the crushing efficiency of the crusher and increasing the need for maintenance work, so as to achieve the effect of avoiding blockage and effective crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

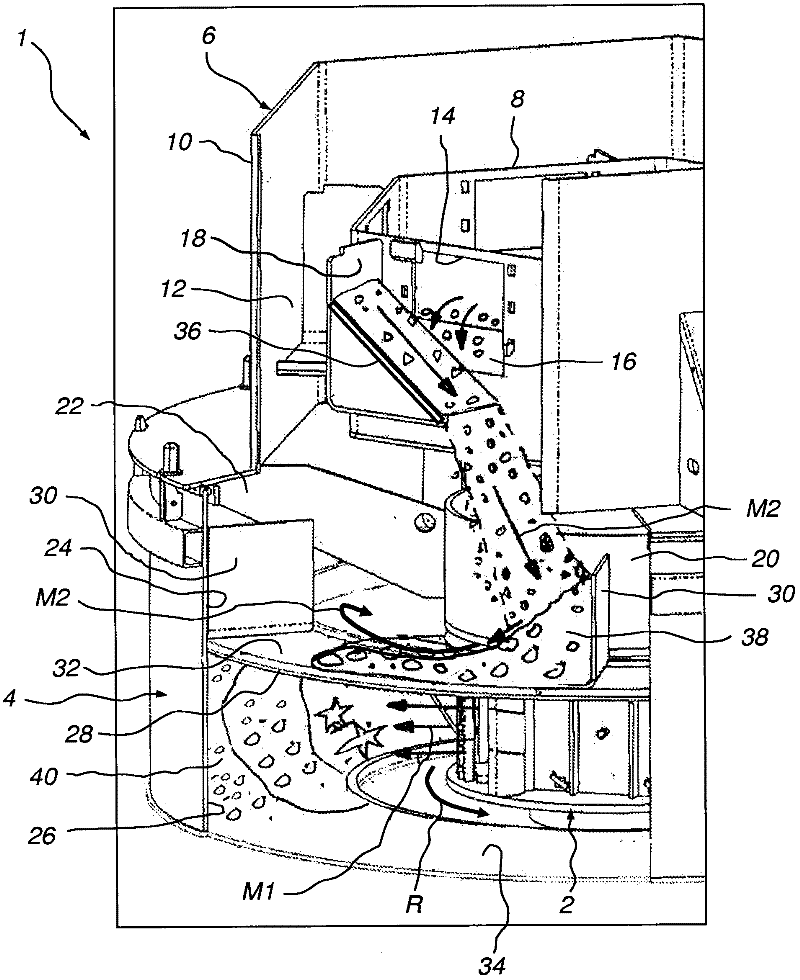

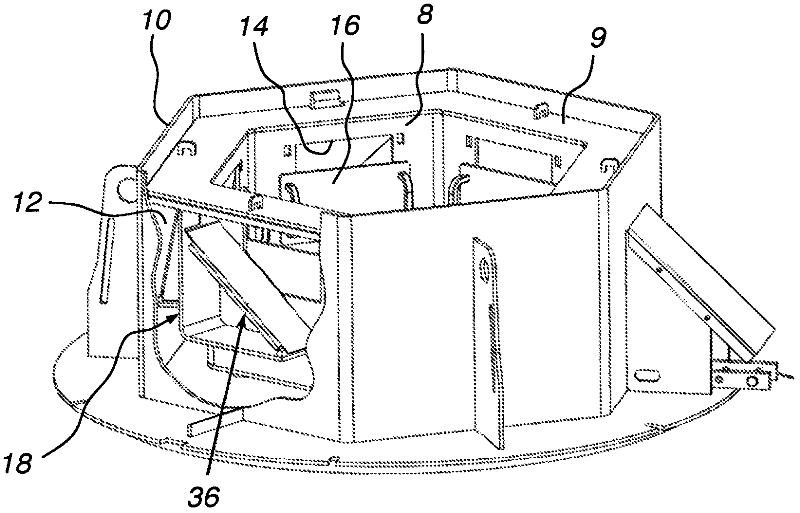

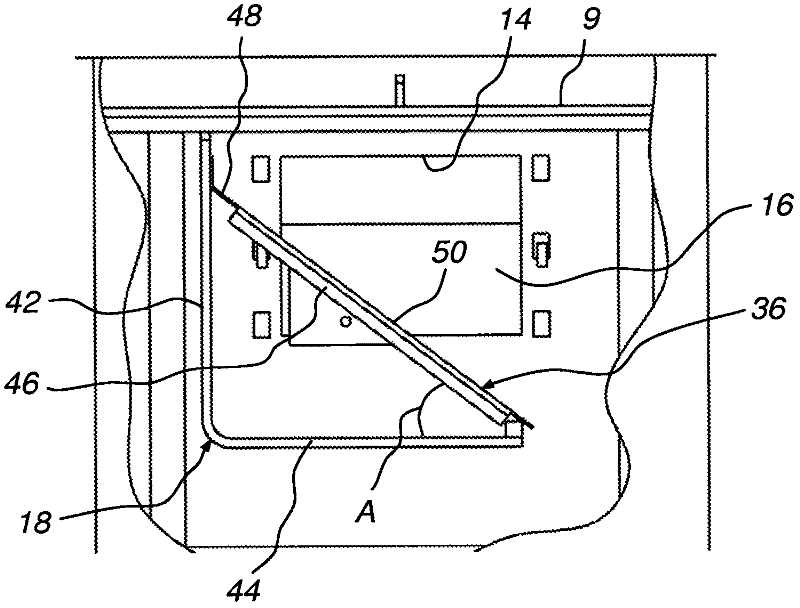

[0024] exist figure 1 In , a vertical shaft impact crusher 1 is shown in partial section. The rotor 2 is located in the housing 4 of the crusher 1 . At the top of the crusher 1 a feed hopper arrangement 6 is placed. The feed hopper arrangement 6 has a hexagonal inner hopper 8 and a hexagonal outer hopper 10 surrounding said inner hopper 8 . figure 1 A cover, not shown, seals the space 12 formed between the inner hopper 8 and the outer hopper 10 from above. The hopper 8 is provided with six outlets 14, each such outlet 14 being placed at one side of the hopper 8 inside the hexagon. Each outlet 14 is provided with a movable flap 16 . The movable flap 16 can be placed at different positions on the inner hopper 8 to obtain the desired opening area of the respective outlet 14 . In said space 12 , near each outlet 14 , an "L"-shaped directional arm 8 is fixed between the inner 8 and outer 10 hoppers. Below the inner hopper 8, a central feed cylinder 20 is placed. The feed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com