Air cooling-dehumidifying method and cooling-dehumidifying air-conditioning system for plant factory

An air-cooling and air-conditioning system technology, applied in air-conditioning systems, botany equipment and methods, ventilation systems, etc., can solve the problems of air-conditioning system energy efficiency ratio reduction, cold source temperature reduction, and system inoperability, etc., to achieve energy efficiency ratio improvement, Reduce condensation temperature, avoid freezing or frosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

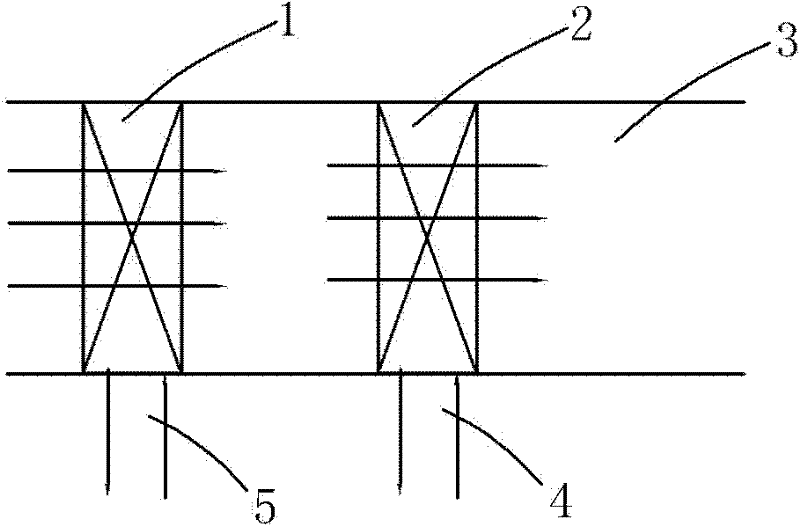

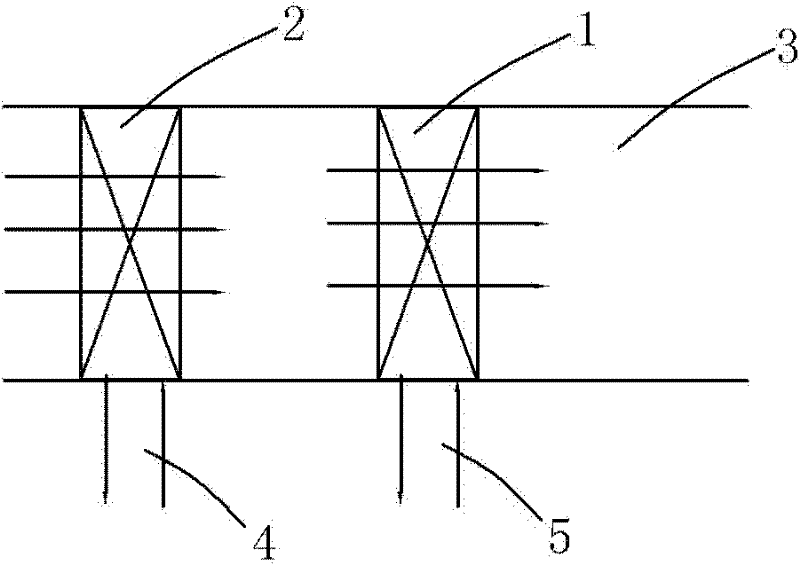

[0040] Example: see figure 1 In the air cooling and dehumidification method of the plant factory of this embodiment, two sets of heat exchangers with a common air duct 3 are arranged in the plant factory, and the two sets of heat exchangers are connected in series in the common air duct before and after.

[0041] In the two sets of heat exchangers, the first heat exchanger is set as the heating coil 1, which first contacts the air to heat the air; the second heat exchanger is set as the cooling coil 2, and the outlet air of the heating coil Perform cooling and dehumidification.

[0042] In practical applications, the heat source of the heating coil 1 is the condensation heat of the refrigeration unit in the plant factory or the heat dissipation of the artificial light source.

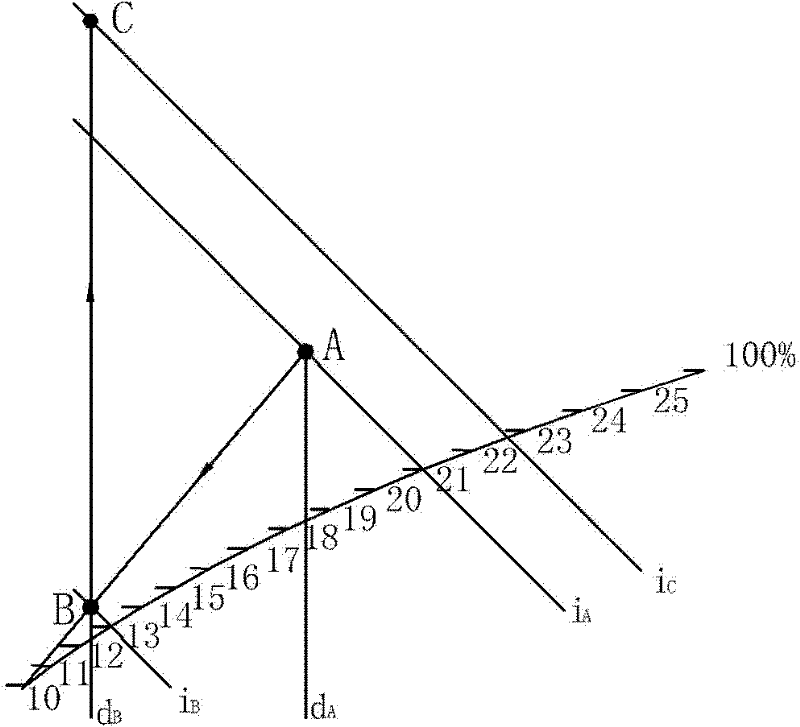

[0043] For the schematic diagram of the cooling and dehumidifying method of the present invention, see figure 1 , The change of air condition in the cooling and dehumidifying air-conditioning system of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com