Hollow fiber film solution composite condensation dehumidification central ventilation system

A fresh air system and fiber membrane technology, which is applied in the field of hollow fiber membrane solution composite condensation dehumidification fresh air system, can solve the problems of reducing the operating stability and service life of the unit, corrosion of pipes and various wall surfaces, and failure to solve equipment corrosion, etc., to achieve energy saving The effect is obvious, the service life is long, and the effect of increasing the temperature of the cold source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

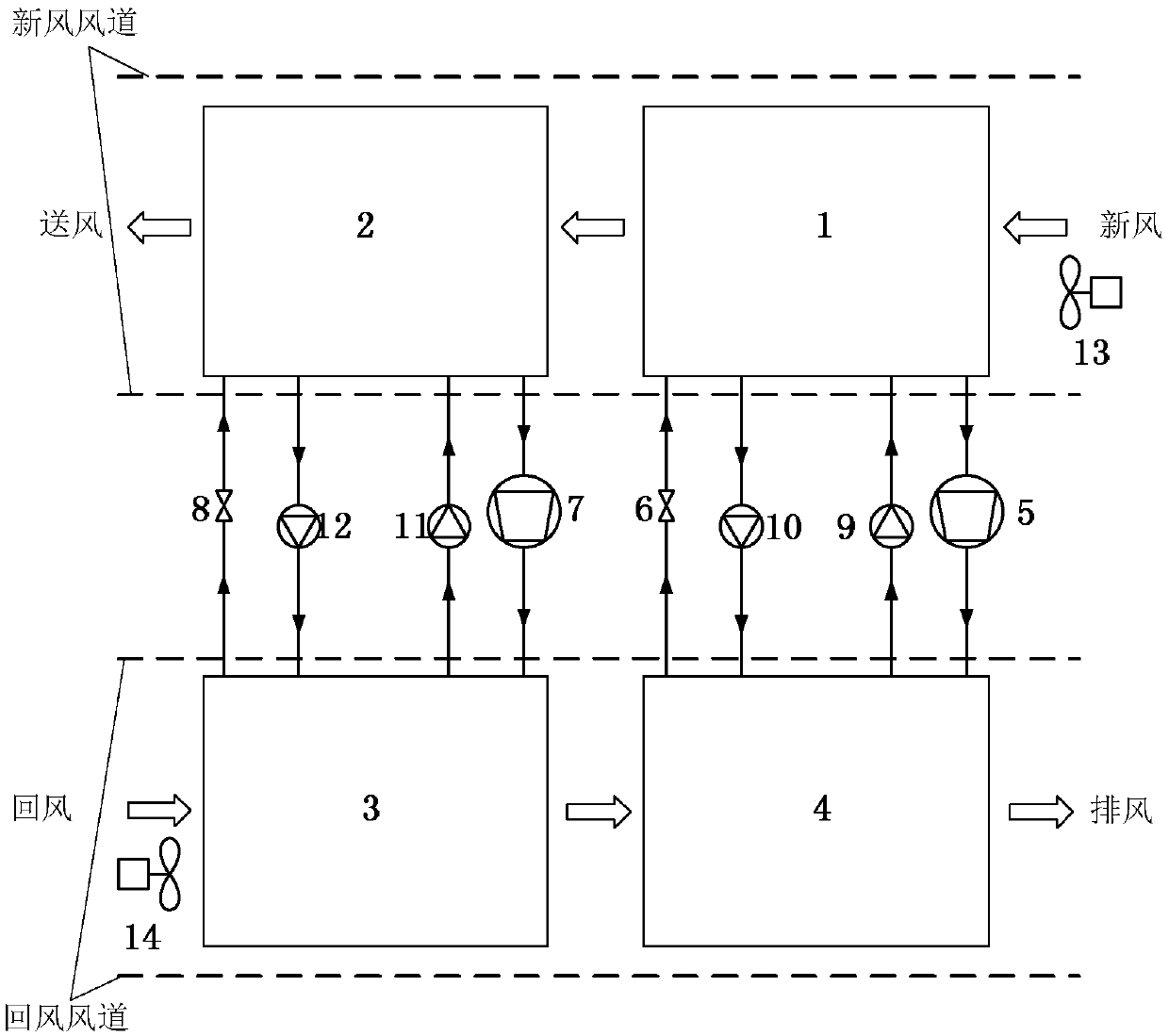

[0033] Attached below Figure 1~4 Specific embodiments of the present invention will be further described.

[0034] The hollow fiber membrane solution composite condensation dehumidification fresh air system of the present invention has a structure such as figure 1 As shown, the system mainly includes two-stage fresh air treatment and return air utilization modules. The main components of the system include 4 air treatment components, 2 sets of vapor compression heat pump devices, and corresponding air and solution circulation devices. For example, the present invention can realize the dehumidification and cooling treatment of fresh air.

[0035] The specific structure and working principle are as follows:

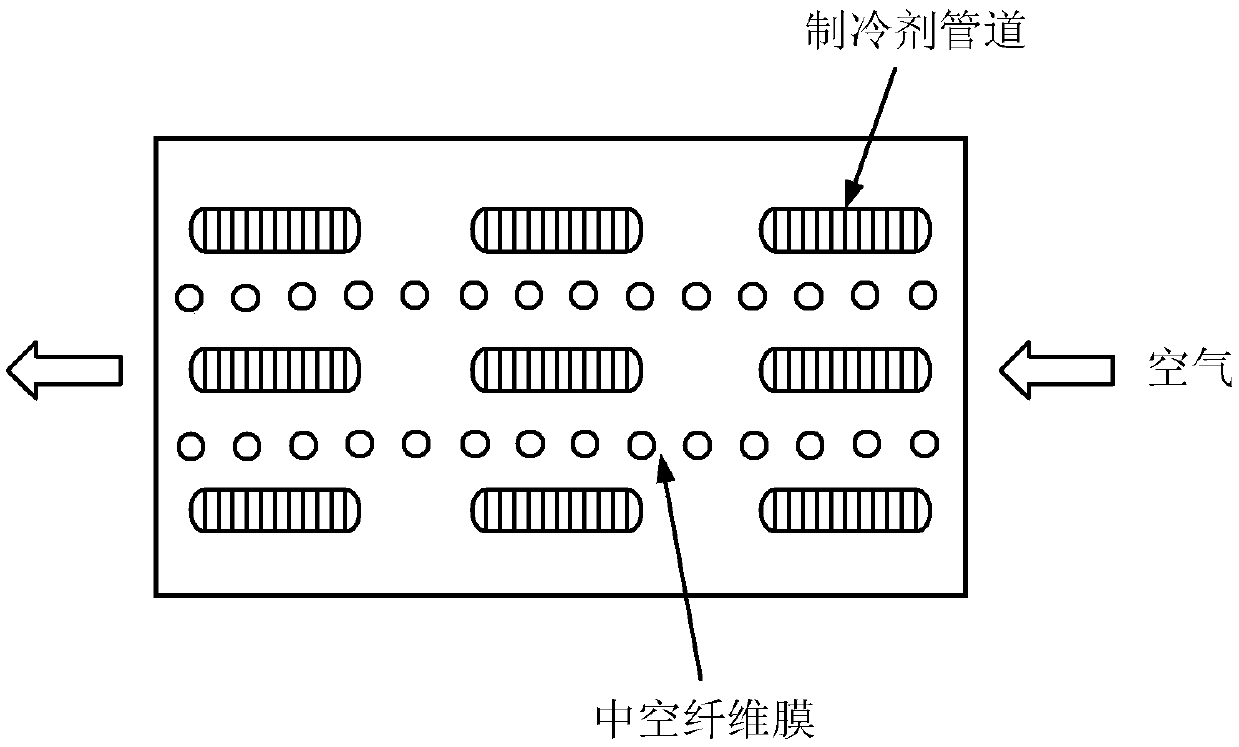

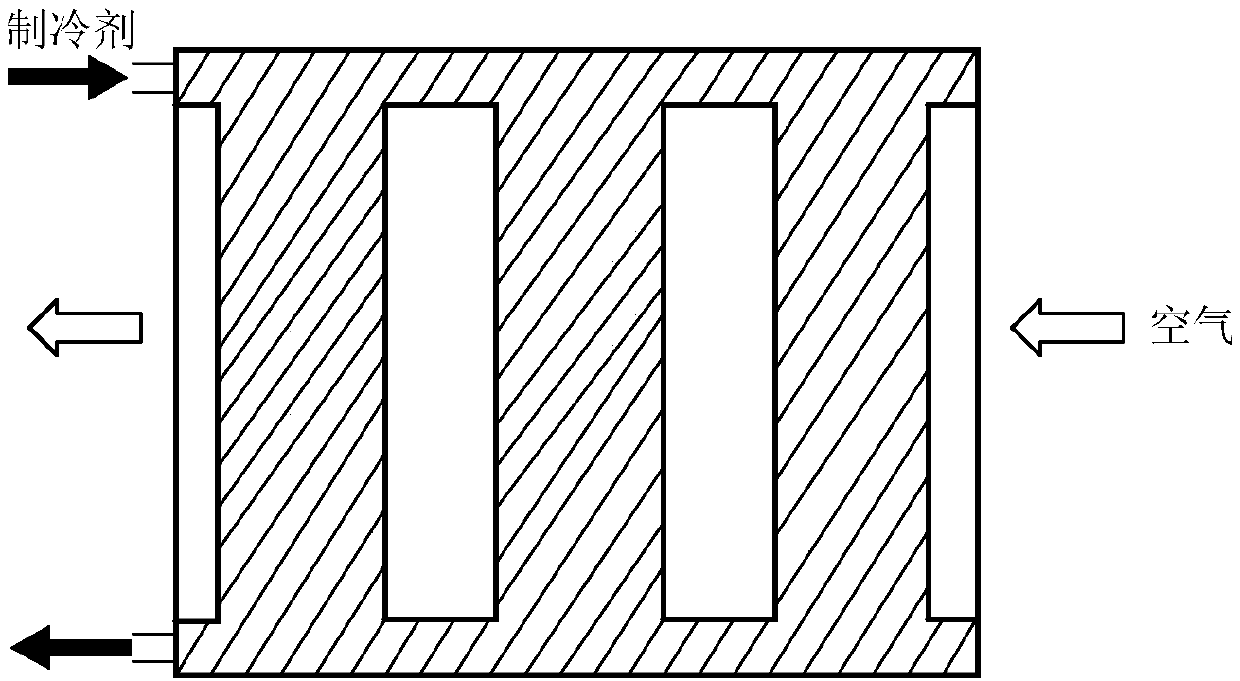

[0036] Specifically, when the unit is turned on, the outdoor fresh air is first sent into the first air processing unit 1 by the first fan 13 from the inlet of the fresh air duct. In the first air module 1, the dehumidification solution (calcium chloride solution) enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com