Slide linkage structure for drawers

A sliding rail connection and drawer technology, which is applied to drawers, furniture parts, household appliances, etc., achieves the effects of low production precision requirements, simple and reasonable structure, and guaranteed reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

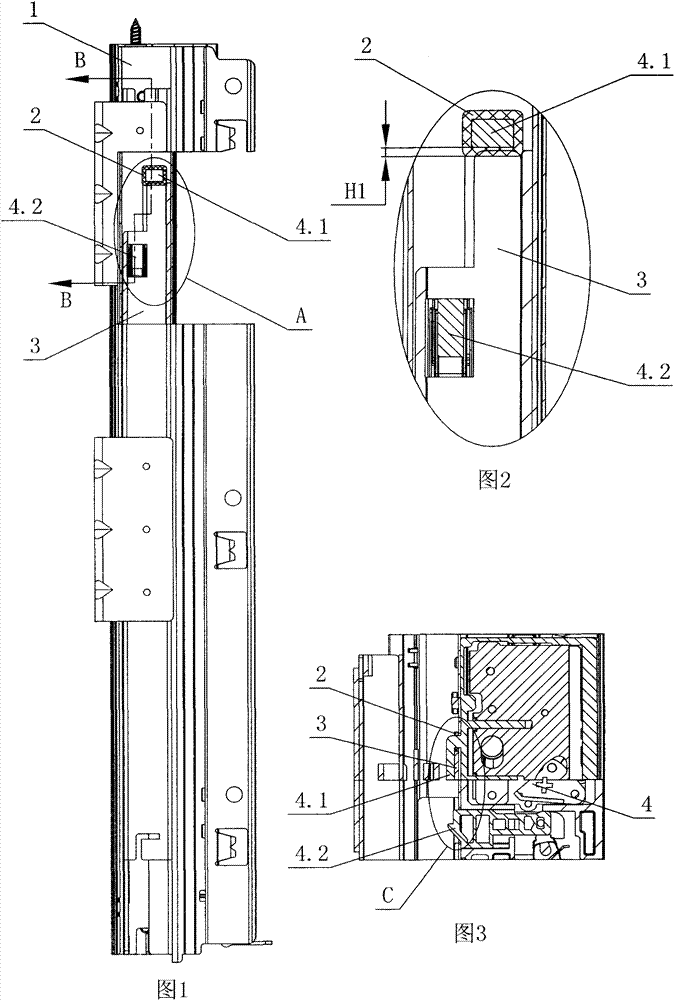

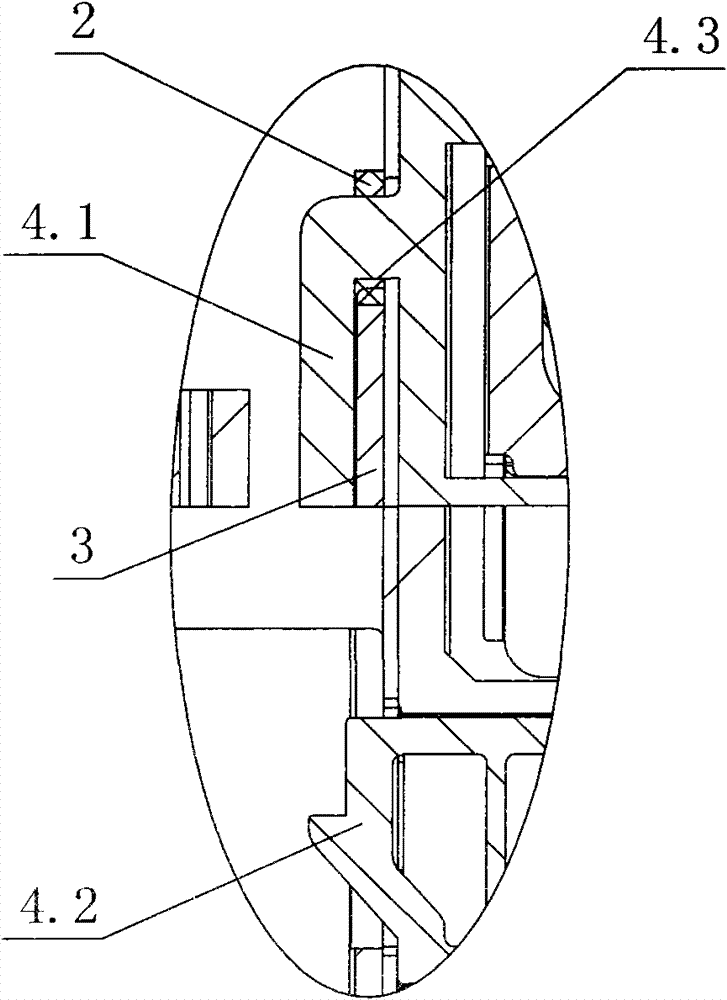

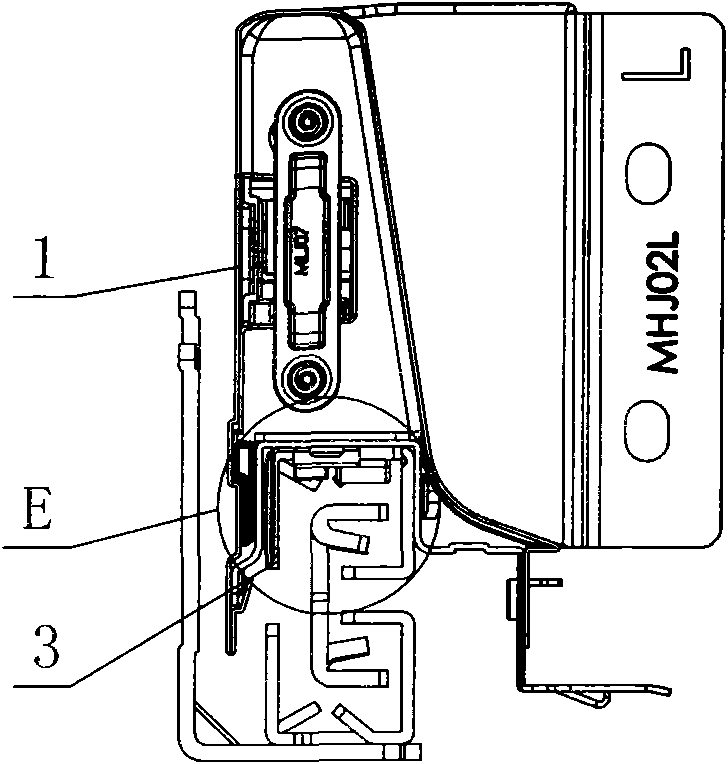

[0030] see Figure 1-Figure 8 , the drawer slide rail connection structure includes a drawer side panel 1 with a panel adjustment device 4 inside, and the front and rear sides of the bottom of the panel adjustment device are respectively provided with a catch hook 4.1 that prevents the moving rail 3 of the slide rail from advancing and a lock that prevents the moving rail from retreating. Tongue 4.2, the catch hook and the lock tongue protrude from the bottom of the side plate of the drawer and connect with the moving rail; the front end of the top of the moving rail is inserted into the catch hook, the front end face 3.1 of the moving rail is in contact with the inner end face 4.3 of the catch hook, and the rear of the front face of the moving rail corresponds The dead bolt is provided with a stop hole 3.2. A gap eliminating component is arranged between the front end surface 3.1 of the moving rail and the inner end surface 4.3 of the retaining hook.

[0031] The gap elimina...

no. 2 example

[0034] see Figure 9-Figure 12 , The gap eliminating component is a cushion 2' made of soft material, which is fixedly connected with the inner end surface 4.3 of the retaining hook in advance by an adhesive. The distance between the front end surface of the lock tongue 4.2 and the inner end surface 4.3 of the retaining hook is L1, the distance between the front end surface of the stop hole 3.2 and the front end surface 4.1 of the moving rail is L2, and the thickness of the cushion 2' is H2; among them, L1 - H2≤L2<L1.

[0035] The above cushion 2' can also be fixedly connected to the front end surface 4.1 of the moving rail in advance through an adhesive, then L2L2. Other unmentioned parts are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com