Special-shape lifting type parking structure

A parking building, lifting technology, applied in the field of special-shaped lifting parking buildings, can solve the problem of low space utilization, achieve low power consumption, improve convenient functions, and eliminate the effects of heating and ventilation facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: Cross-shaped lifting parking building

[0030] 1. Parking structure

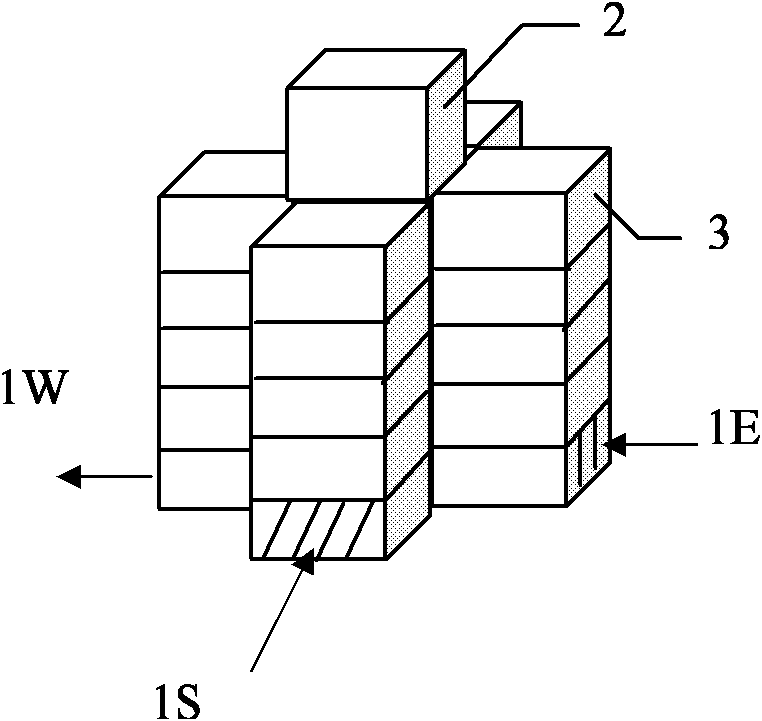

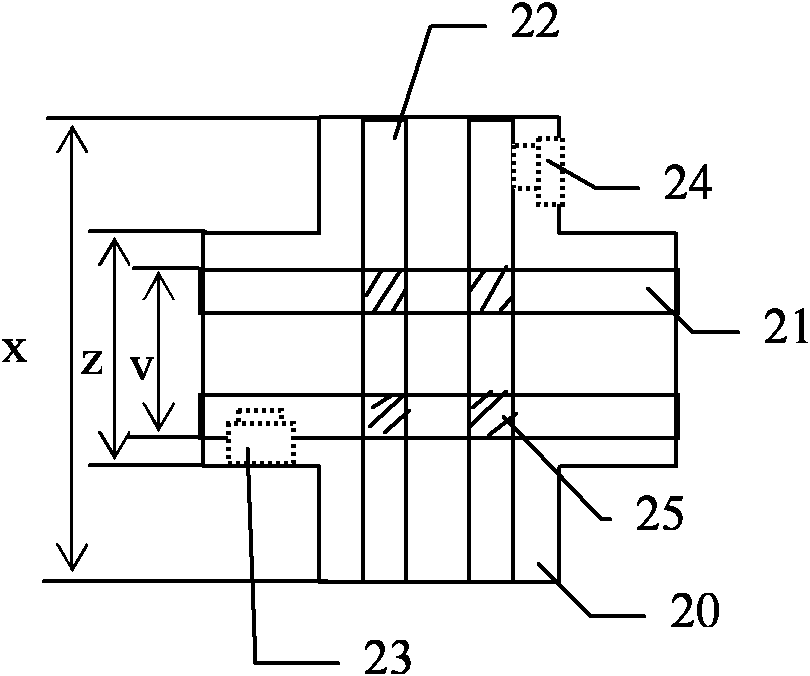

[0031] The plane of the parking building is cross-shaped. Such as figure 1 As shown, the cross-shaped lifting parking building adopts a modular design, including an entrance and exit part 1, a lifting part 2 and a storage part 3. in:

[0032] Entrance and exit: The vehicle entrance and exit is located on the ground floor of the parking building. Taking into account the driver's driving habit in the straight direction, that is, the entrance of the east to send the car in, the exit of the west to pick up the car and drive out: the entrance to the south to send the car in, the exit to the north to pick up the car and drive out, the vehicle entrance and exit are divided into east-west pairs Vehicle import and export 1E (entry), 1W (exit) and a pair of north-south vehicle import and export 1S (entrance), 1N (exit).

[0033] Storage part: It consists of four storage garages in the southea...

Embodiment 2

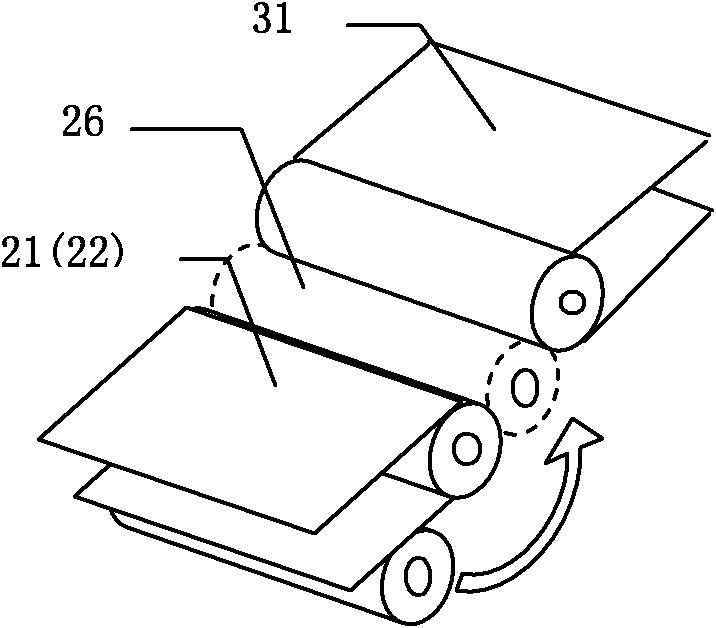

[0059] Embodiment 2: Cross-shaped lifting parking building

[0060] The plane of the parking building is still cross-shaped, but on the basis of Embodiment 1, a pair of roller belts opposite to the roller belts of the car floor are laid on the ground of the vehicle entrance passage and the exit passage, so that the car can be moved from the entrance to the entrance. Transport to or from the elevator car to the exit. The intermediate wheel transmission is adopted between the roller belt and the conveyor belt of the car.

[0061] Its working principle is: when the car drives in, it stops on the roller belt of the entrance channel, the driver gets off, and the roller belt moves the car into the lifting part. When driving out, the lifting part sends the car into the exit passage, and the driver takes the car.

Embodiment 3

[0062] Embodiment 3: T-shaped lifting parking building

[0063] The difference from the foregoing embodiments is that the plane of the parking building is T-shaped. The storage workshops on each floor include three storage workshops in the east, west, and north. On the ground floor of the parking building, cars can enter and exit from the east-west direction, or from the north. The elevator shaft is located at the intersection of the east, west and north storage workshops.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com