Direct inserted light emitting diode (LED) radiating unit and radiating system

A heat dissipation unit and heat dissipation system technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of high consumption of chemical raw materials, unsatisfactory heat dissipation effect, high labor costs, etc., achieve good heat dissipation effect, simple and reasonable structure, The effect of saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment b2

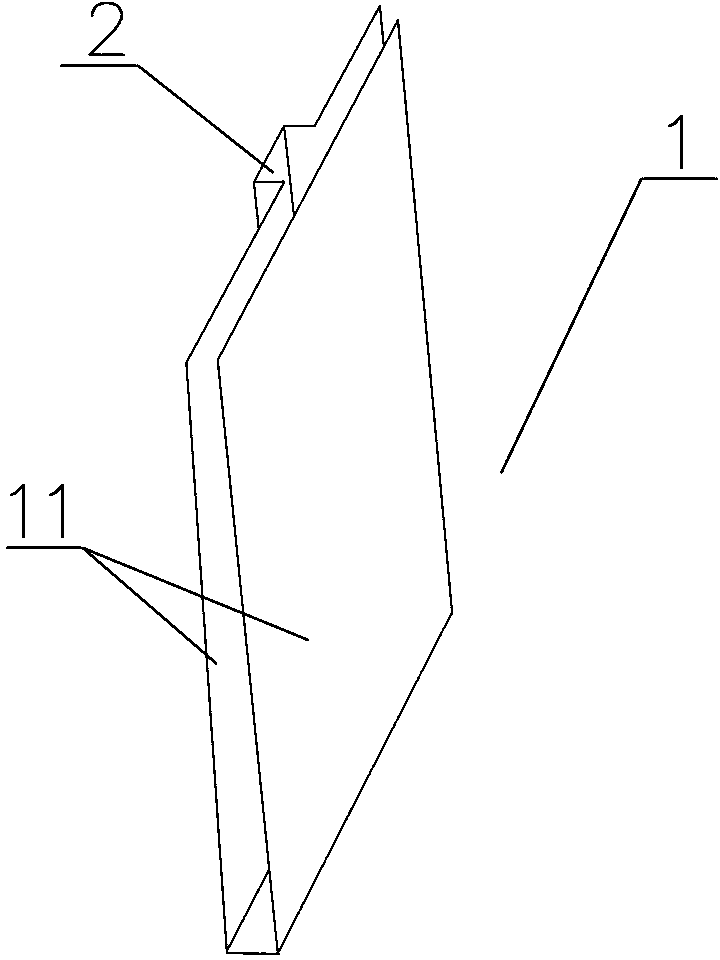

[0033] Embodiment b2: with reference to Figure 4 , connecting the lower extension parts of the plurality of in-line LED cooling fins in sequence as described in embodiment a2, and paying attention to staggering the installation grooves 2 on both sides at intervals to form the in-line LED cooling unit. In actual production, the specific processing details of this in-line LED heat dissipation unit can be the same as that of embodiment b1, and correspondingly, plug pins should be left at the lower extension of the clip 11 to facilitate the connection with peripheral devices. Combination with lighting frame or circuit board mounting frame.

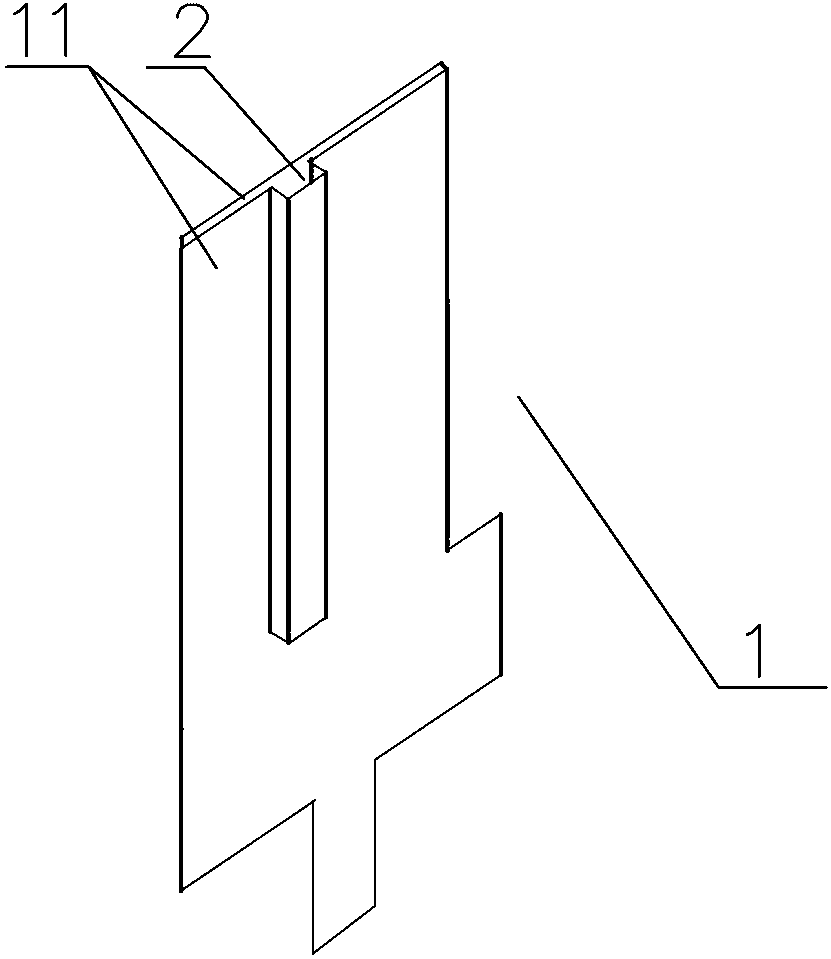

[0034] Embodiment c1 of in-line LED cooling system: refer to Figure 5 , an in-line LED heat dissipation system, which includes a plurality of in-line LED heat dissipation units, and the plurality of in-line LED heat dissipation units are arranged in parallel in multiple rows.

[0035] As a further preferred embodiment, among any two adjace...

Embodiment c2

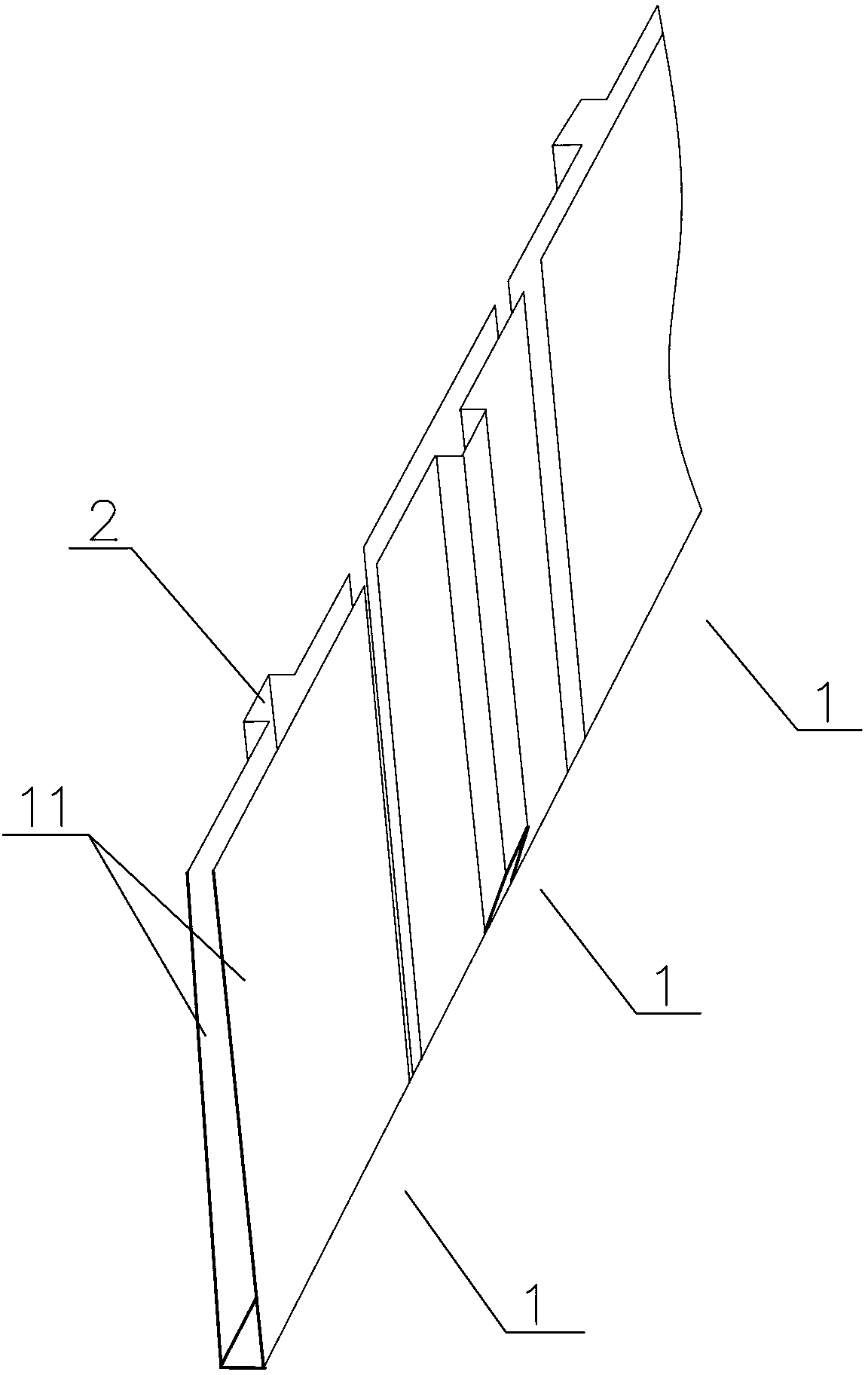

[0036] Embodiment c2: with reference to Image 6 , making the in-line LED heat dissipation system ring-shaped, that is, the in-line LED heat dissipation unit is in a ring structure, and the multiple in-line LED heat dissipation units are arranged in a multi-layer ring array.

[0037] As a further preferred embodiment, in any two adjacent layers of the ring-shaped in-line LED heat dissipation units, at least two mounting grooves 2 have protruding directions facing each other and facing each other. In some occasions, it may be necessary to arrange a ring-shaped LED array. By making the in-line LED heat dissipation unit ring-shaped and surrounding it in multiple layers, a planar ring-shaped array of multiple installation slots 2 in groups of two is formed. The requirement that the protruding directions of at least two installation grooves 2 in any adjacent two layers of the ring-shaped in-line LED heat dissipation units face each other and face each other is actually the same as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com